Technology method using siltstone for manufacturing stone pot

A process method and siltstone technology are applied in the field of making stone pots with siltstone, which can solve problems such as difficult processing, and achieve the effects of changing processing performance, improving machinability and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

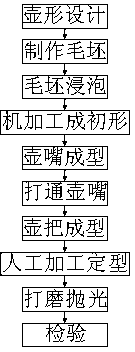

Image

Examples

Embodiment 1

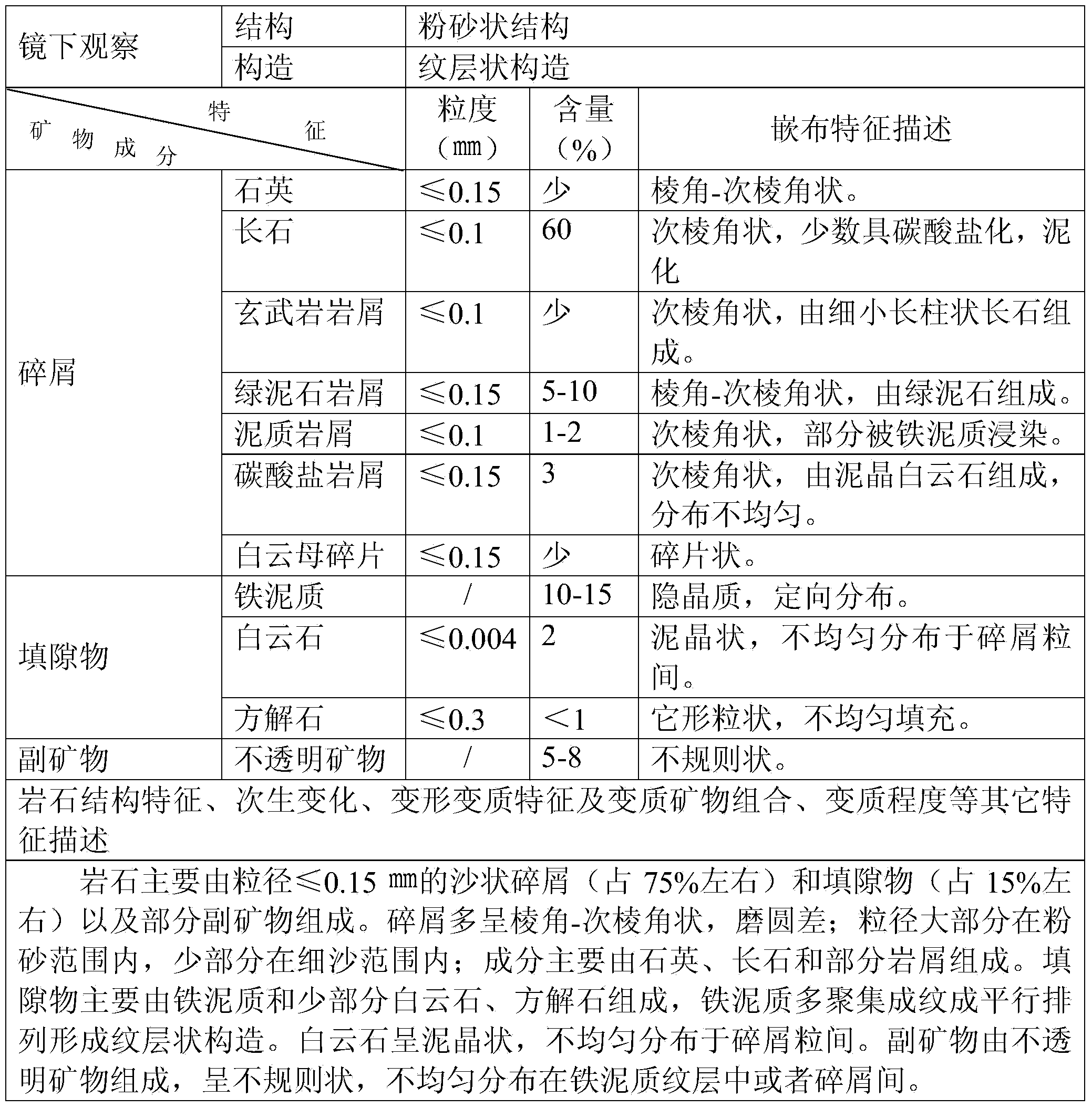

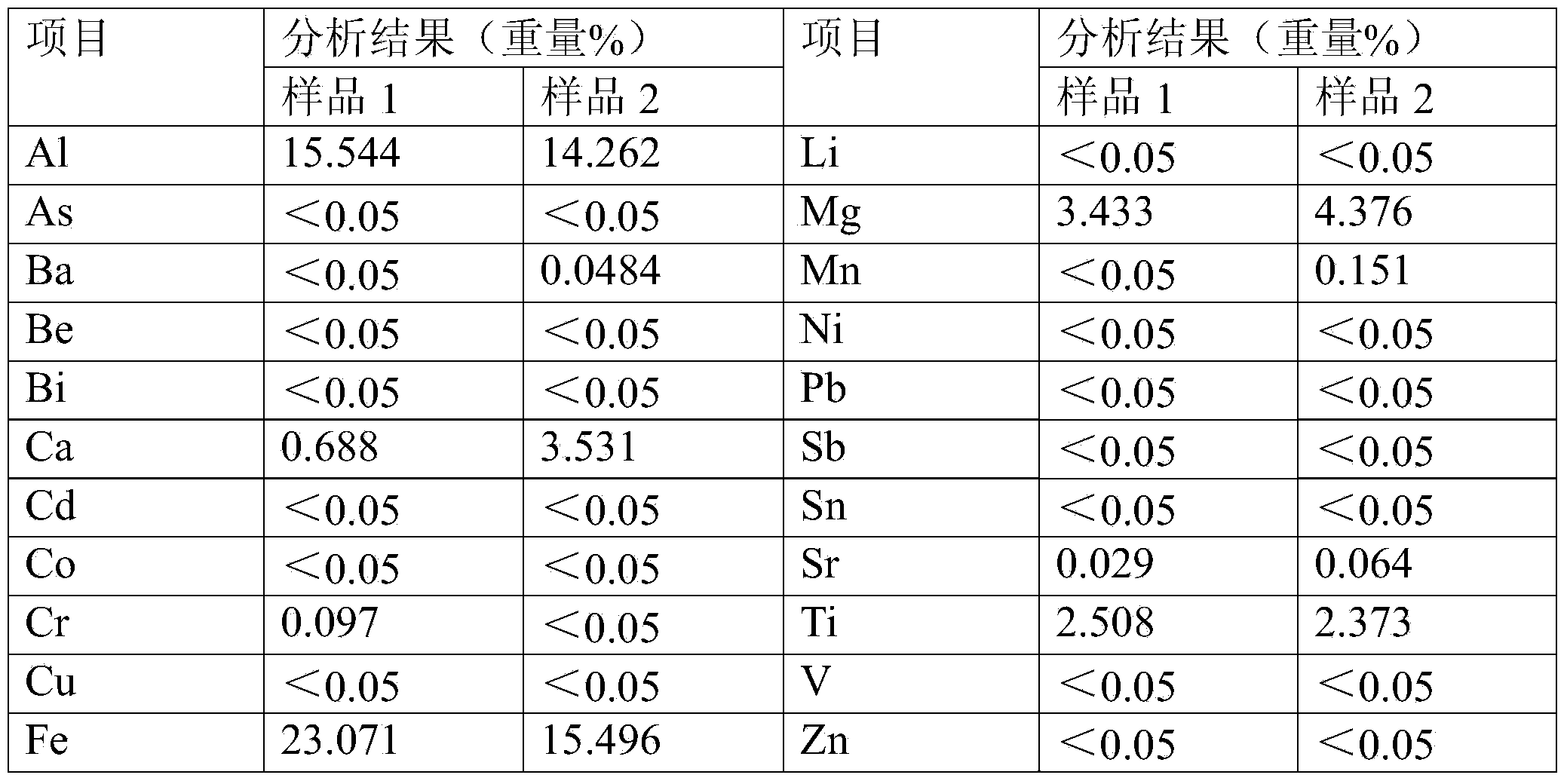

[0026] Example 1, choose siltstone from Hebatou, Zhenxiong County, Yunnan Province, which is purple and gray-green laminated mud, and process one hundred stone pots with a wall thickness of 5mm, including the following steps:

[0027] (1) Pot shape design, design the pot shape and draw drawings according to the stone pattern of siltstone;

[0028] (2) making blanks, cutting large pieces of siltstone into small blanks according to the design requirements;

[0029] (3) soaking the blank, soaking the blank in cold water, the soaking time is two days;

[0030] (4) Machining into a preliminary shape, taking out the soaked blank, drawing a line on the blank according to the design drawing, using a milling machine and an engraving machine to mill and engrave the inner cavity and outer wall of the blank to form a semi-finished teapot;

[0031] (5) The spout is formed, and the shape of the spout is processed by an engraving machine;

[0032] (6) To get through the spout, a 4 mm engra...

Embodiment 2

[0038] Example 2, choose siltstone from Hebatou, Zhenxiong County, Yunnan Province, which is purple and gray-green laminated mud, and process one hundred stone pots with a wall thickness of 5mm, including the following steps:

[0039] (1) Pot shape design, design the pot shape and draw drawings according to the stone pattern of siltstone;

[0040] (2) making blanks, cutting large pieces of siltstone into small blanks according to the design requirements;

[0041] (3) the blank is soaked, the blank is soaked in cold water, and the soaking time is five days;

[0042] (4) Machining into a preliminary shape, taking out the soaked blank, drawing a line on the blank according to the design drawing, using a milling machine and an engraving machine to mill and engrave the inner cavity and outer wall of the blank to form a semi-finished teapot;

[0043] (5) The spout is formed, and the shape of the spout is processed by an engraving machine;

[0044] (6) To get through the spout, the...

Embodiment 3

[0050] Example 3, choose siltstone from Hebatou, Zhenxiong County, Yunnan Province, which is purple and gray-green laminated mud, and process one hundred stone pots with a wall thickness of 5mm, including the following steps:

[0051] (1) Pot shape design, design the pot shape and draw drawings according to the stone pattern of siltstone;

[0052] (2) making blanks, cutting large pieces of siltstone into small blanks according to the design requirements;

[0053] (3) blank is soaked, and blank is soaked in cold water, soaking time is 15 days;

[0054] (4) Machining into a preliminary shape, taking out the soaked blank, drawing a line on the blank according to the design drawing, using a milling machine and an engraving machine to mill and engrave the inner cavity and outer wall of the blank to form a semi-finished teapot;

[0055] (5) The spout is formed, and the shape of the spout is processed by an engraving machine;

[0056] (6) To get through the spout, the 8 mm engravin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com