Continuous high-temperature tempered noodle device and process

A high-temperature tempering and dried noodle technology, which is applied in dough processing, baking, food science, etc., can solve the problems of shortening drying time and large area of drying room, so as to shorten drying time, overcome taste deterioration, The color has a gelatinous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

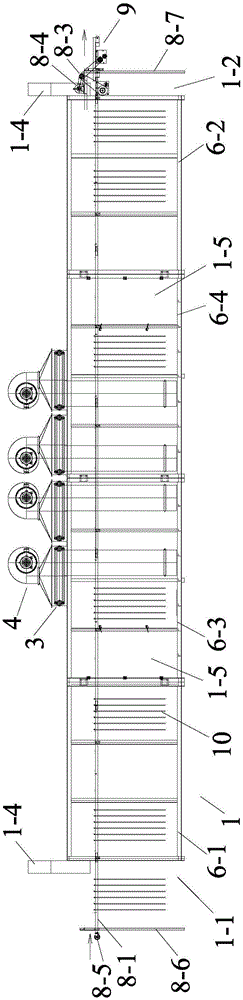

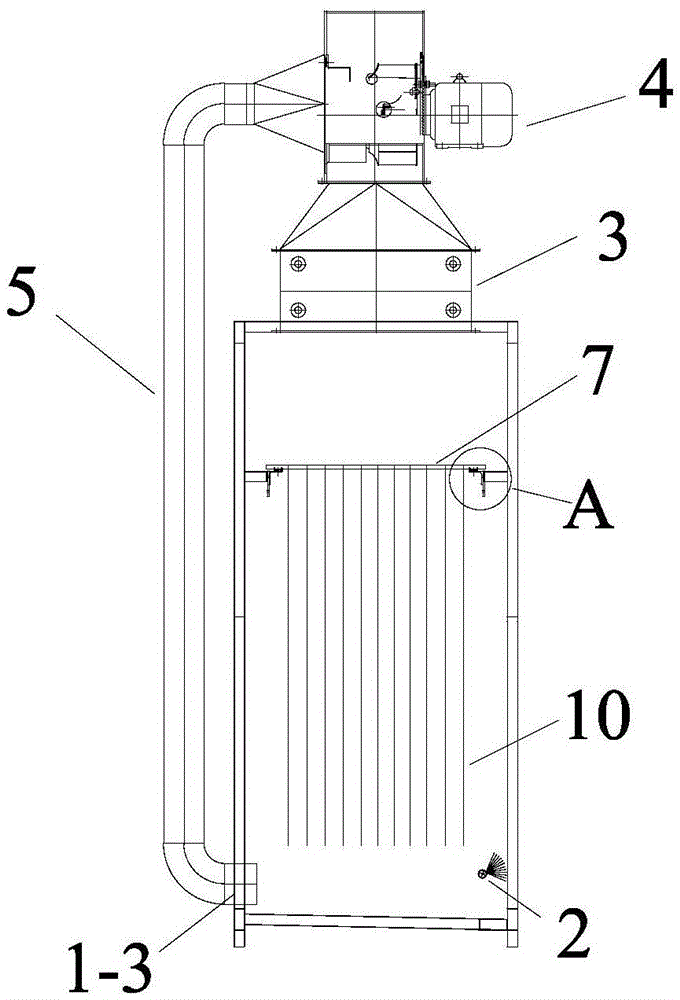

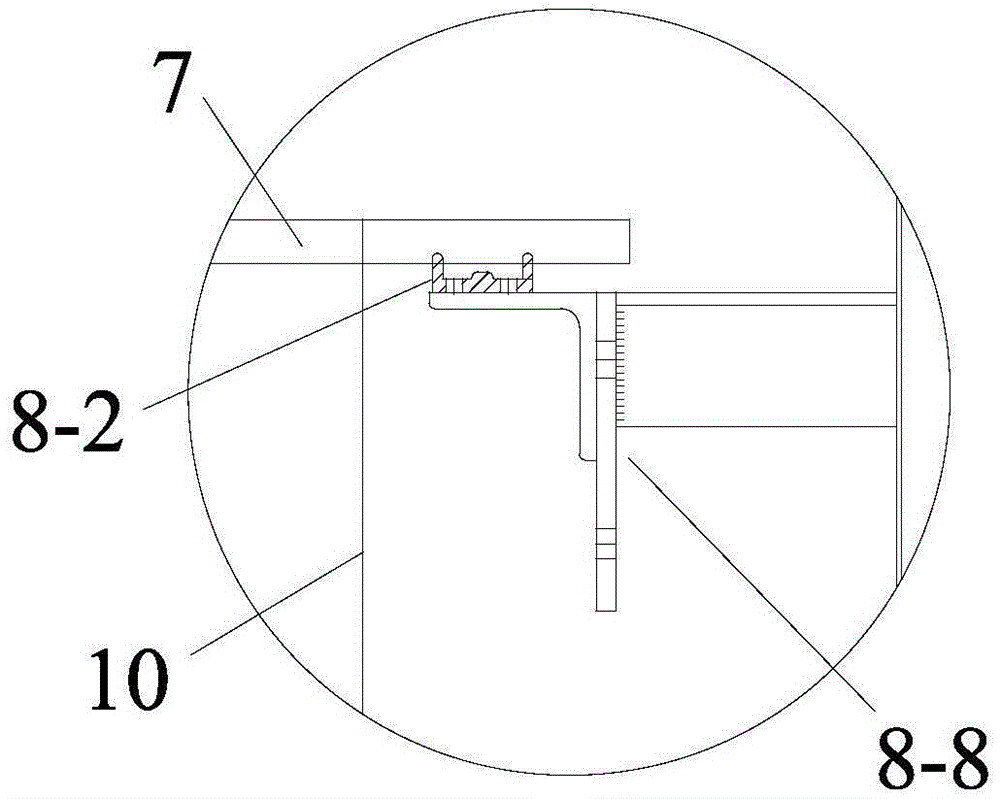

[0032] like Figure 1 to Figure 3 As shown, the continuous high-temperature conditioning and tempering noodle device of the present embodiment includes a box body 1, one end of the box body 1 is an inlet 1-1, and the other end is an outlet 1-2; the middle section of the box body 1 is a heating and humidifying zone; the heating and humidifying zone The lower part of the box body is provided with a steam nozzle 2 connected to an external steam source, and the top of the box body in the heating and humidifying area is provided with a steam heater 3 with a steam outlet connected to the box body 1, the steam heater 3 steam inlet and the circulation fan 4 air outlet Connected, the air inlet of the circulation fan 4 communicates with the box body 1 through the circulation air duct 5 and the circulation air outlet 1-3 at the lower part of the side wall of the box body in the heating and humidifying area in turn. The steam nozzle 2 is arranged along the length direction of the box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com