Arrangement structure of handle seat, rear wheel assembly and power assembly of a portable tillage machine

A technology of power assembly and layout structure, applied in the field of micro-tiller, can solve the problems of inconvenient selection of suitable power for the micro-tiller, complicated installation process of the worm gear box, and reduced working efficiency of the micro-tiller, etc. Reliable tube, easy to cross obstacles, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

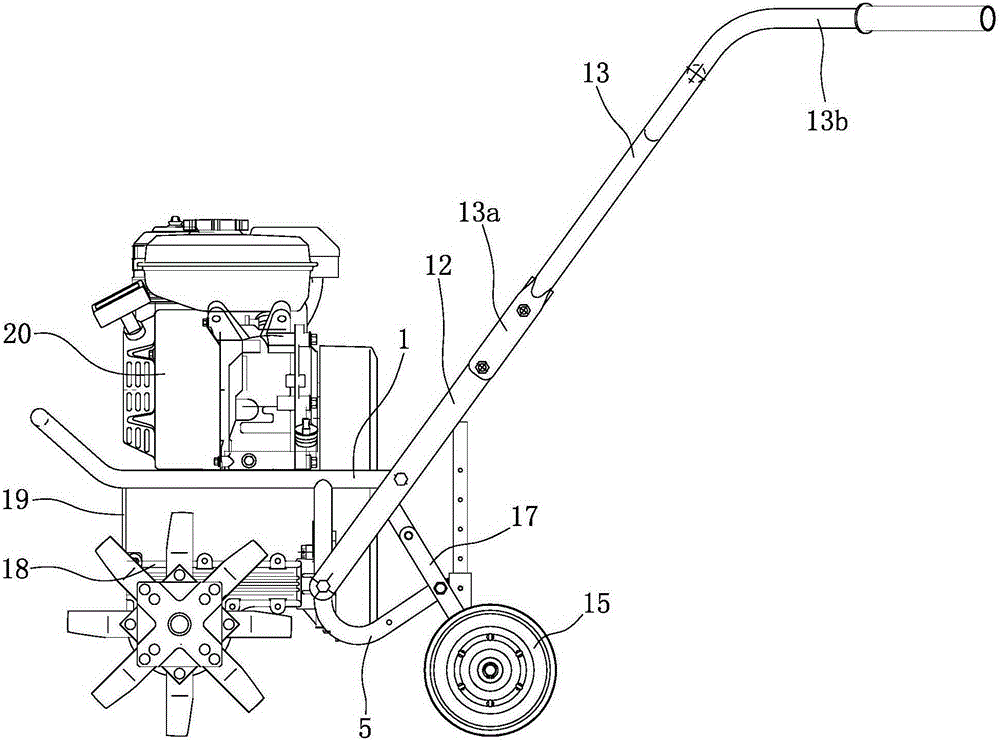

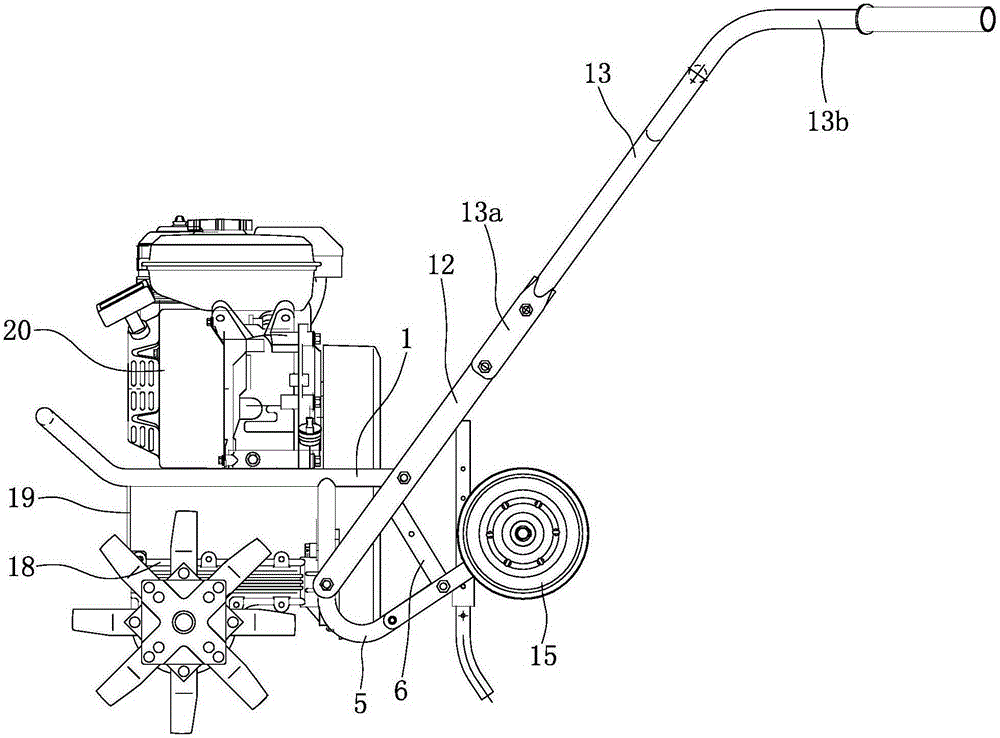

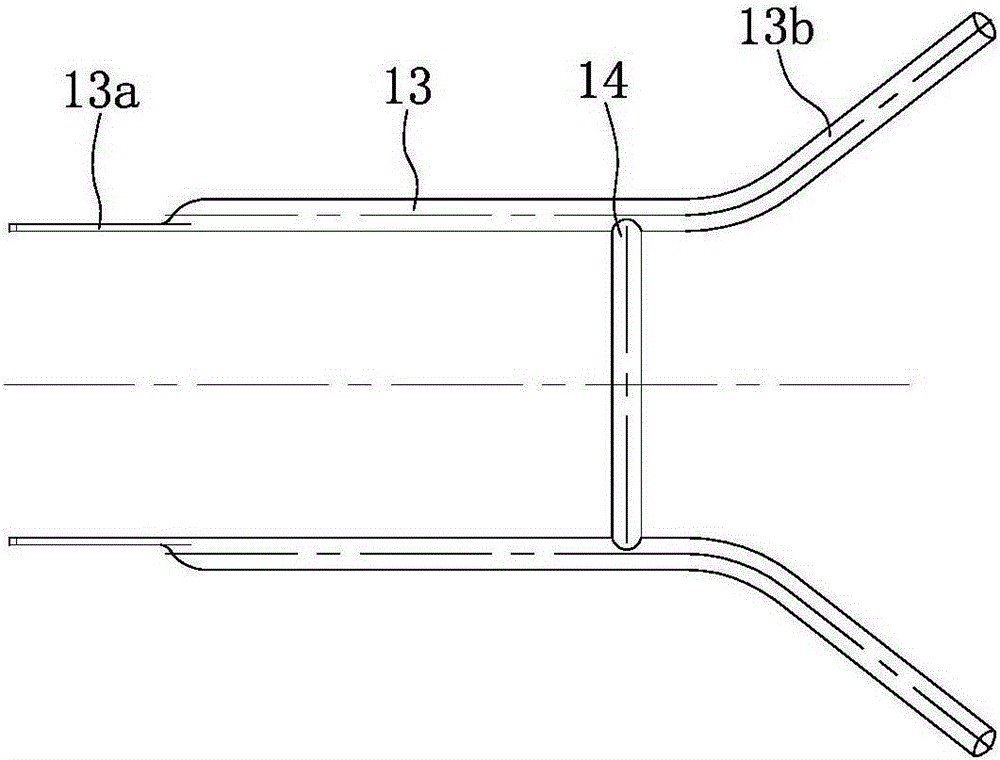

[0032] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 As shown, the frame consists of a main pipe 1, a beam 2, a supporting plate 3, a plug 4, an elbow 5, an inclined pipe 6, a horizontal pipe 7, a positioning sleeve 8, a stopper 9, an upper positioning plate 10 and a lower positioning plate 11, etc. constitute. Wherein, the main pipe 1 is in a "U" shape with the front end closed and the rear end open, and the front end of the main pipe 1 is tilted up to form a bumper 1a. Except for the bumper 1a, the remaining part of the main pipe 1 is a horizontal section symmetrically arranged on the left and right sides, and the bumper 1a and the horizontal section of the main pipe 1 have an included angle of 130-150°. A crossbeam 2 is arranged at the front between the two horizontal sections of the main pipe 1. The crossbeam 2 is a rectangular pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com