Hard coating composition

A technology of hard coating and composition, applied in the direction of coating, epoxy resin coating, etc., can solve the problems such as difficult to form a high-hardness protective layer, and achieve improved storage stability, good elongation, transparency and elongation sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

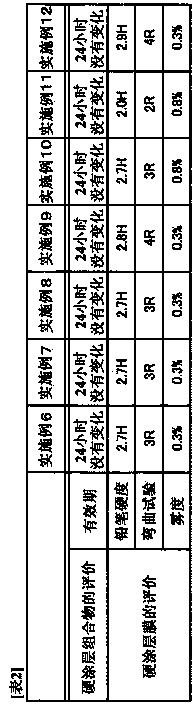

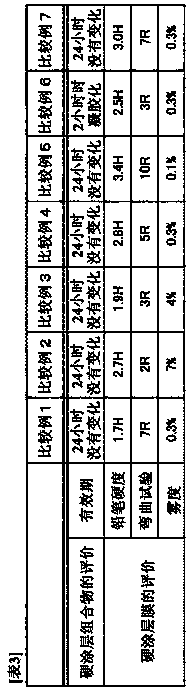

Examples

Embodiment 1

[0111]JER1009 (bisphenol A type epoxy resin, number average molecular weight 3800, manufactured by Mitsubishi Chemical Corporation) solid content 15 parts by mass, Cymel 325 (melamine resin, melamine mononuclear body content rate 48% by mass, manufactured by Japan Cytech Indastries Co., Ltd.) Components 30 parts by mass, Ilugakyua 184 (1-hydroxy-cyclohexyl-phenyl-ketone, manufactured by BASF Corporation) 5 parts by mass of solid content, and Aronics M400 (a mixture of dipentaerythritol pentaacrylate and dipentaerythritol hexaacrylate, Toagosei Co., Ltd.) 50 parts by mass of solid content was mixed with methyl ethyl ketone to obtain 40 mass % of non-volatile content to obtain a hard coat composition.

[0112] The obtained hard coat composition was coated on a PET film (thickness 100 μm) with a bar coater, and heated at 150° C. for 1 minute to remove the solvent to obtain a thermosetting hard coat layer with a film thickness of 5 μm.

[0113] Then use the hard coating with a hig...

Embodiment 2

[0115] Except having changed jER1009 into jER1004 (bisphenol A type epoxy resin, number average molecular weight 1400, the Mitsubishi Chemical Corporation make), it carried out similarly to Example 1, and obtained the hard-coat composition and hard-coat film.

Embodiment 3

[0117] Except having changed jER1009 into jER1010 (bisphenol A type epoxy resin, number average molecular weight 5500, the Mitsubishi Chemical Corporation make), it carried out similarly to Example 1, and obtained the hard-coat composition and hard-coat film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com