Flexible optical diffusion barrier and preparation method thereof

An optical diffusion and flexibility technology, applied in optics, optical components, instruments, etc., can solve the problems of easy bending, product quality decline, scratches on prism film, etc., to reduce defective rate, good flexibility, good adhesion focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

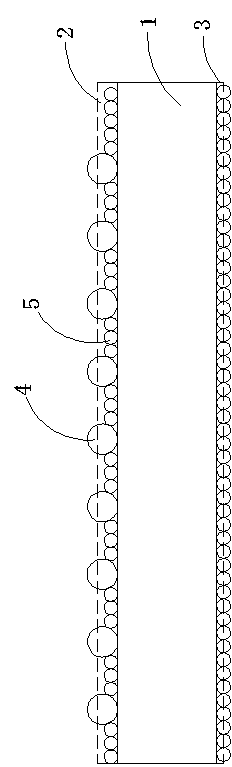

[0033] A flexible optical diffusion film, comprising a substrate layer 1, the upper surface of the substrate layer 1 is coated to form a flexible optical diffusion layer 2, the lower surface of the substrate layer 1 is coated to form an anti-adhesive layer 3, the flexible optical diffusion The parts by weight of the coating solution composition formula of layer 2 are: 24 parts of resin film formers; 5 parts of diffusion particles; 1 part of crosslinking agent; 70 parts of solvent; : 24 parts of resin film former, 5 parts of anti-adhesive particles; 1 part of crosslinking agent; 70 parts of solvent.

[0034] Wherein, the substrate layer 1 is made of polyethylene terephthalate resin film.

[0035] Flexible optical diffusion layer 2: the resin film former is polyethylene adipate in linear hydroxyl polyester resin; diffusion particles: the weight ratio of the first PMMA particle 4 and the second PMMA particle 5 is 4:1 , respectively 4 parts and 1 part, the particle size ratio of ...

Embodiment 2

[0045] A flexible optical diffusion film, comprising a substrate layer 1, the upper surface of the substrate layer 1 is coated to form a flexible optical diffusion layer 2, the lower surface of the substrate layer 1 is coated to form an anti-adhesive layer 3, the flexible optical diffusion The parts by weight of the coating solution composition formula of layer 2 are: 15 parts of resin film formers; 30 parts of diffusion particles; 5 parts of crosslinking agent; 50 parts of solvent; : 15 parts of resin film former, 30 parts of anti-adhesive particles; 5 parts of crosslinking agent; 50 parts of solvent.

[0046] Wherein, the substrate layer 1 is made of polystyrene resin film.

[0047] Flexible optical diffusion layer 2: the resin film former is polyurethane elastomer modified polyester resin is polyurethane modified polyethylene adipate; diffusion particles: the weight ratio of the first PMMA particle 4 and the second PMMA particle 5 9:1, respectively 27 parts and 3 parts, th...

Embodiment 3

[0057] A flexible optical diffusion film, comprising a substrate layer 1, the upper surface of the substrate layer 1 is coated to form a flexible optical diffusion layer 2, the lower surface of the substrate layer 1 is coated to form an anti-adhesive layer 3, the flexible optical diffusion The parts by weight of the coating solution composition formula of layer 2 are: 30 parts of resin film formers; 24 parts of diffusion particles; 3 parts of crosslinking agent; 43 parts of solvent; : 30 parts of resin film former, 24 parts of anti-adhesion particles; 3 parts of crosslinking agent; 43 parts of solvent.

[0058] Wherein, the substrate layer 1 is made of polycarbonate resin film.

[0059] Flexible optical diffusion layer 2: the resin film former is polybutylene adipate in linear hydroxyl polyester resin; diffusion particles: the weight ratio of the first PMMA particle 4 and the second PMMA particle 5 is 7:1 , respectively 21 parts and 3 parts, the particle size ratio of the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com