Fuze rotary demounting device for small-caliber aircraft projectiles

A small-caliber, fuze technology, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of no fuze, automatic unscrew and difficulty, and achieve reliable positioning, automatic splitting, and reliable clamping.

Inactive Publication Date: 2014-09-10

CHANGCHUN EQUIP TECH RES INST

View PDF4 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Usually, the fuze of the small-caliber projectile and the warhead are connected by threads, and the disassembly method basically adopts the unscrewing method. Since the shape of the fuze is mostly conical and streamlined, it brings great difficulties to its automatic unscrewing. No fuze automatic splitting device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

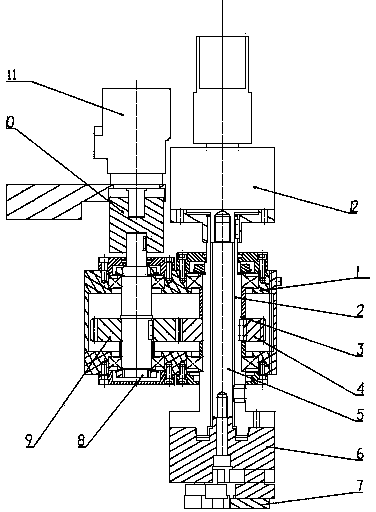

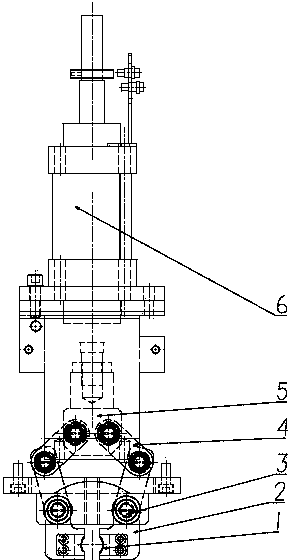

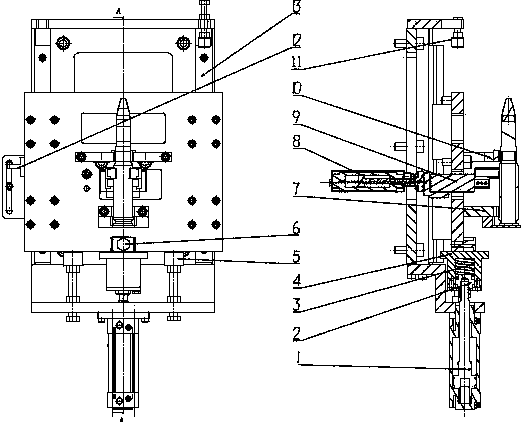

The invention relates to a fuze rotary demounting device for small-caliber aircraft projectiles and belongs to an automatic demounting line for the small-caliber aircraft projectiles. The fuze rotary demounting device comprises a rotary demounting power head, a projectile positioning clamping mechanism, a positioning lifting slide table, a fuze-moving-out mechanical arm, a counter weight mechanism and a rack. A hydraulic floating jaw and a spring seat are used for solve the key technical problem of fuze streamline conical surface clamping, reliable projectile positioning is guaranteed by the shape-following design of the cartridge jaw, and safe and reliable operation of the device is guaranteed by the clamping force for hydraulic clamping a fuze and a battle part. A rotary demounting separating end falls by the aid of the axial force and self weight, rotary demounting is performed according to screw pitch, and disordered fastening is avoided. By the fuze rotary demounting device, safe, fast and automatic fuze rotary demounting is achieved through electric, gas and liquid linkage control, automatic demounting of the small-caliber aircraft projectiles is achieved, and good technical support is provided for retired ammunition demounting.

Description

technical field The invention belongs to the technical field of automatic disassembly of decommissioned ammunition, and is particularly suitable for the safe automatic disassembly of fuzes of small-caliber artillery shells. Background technique Due to inventory pressure, environmental protection requirements and safety considerations, the dismantling, destruction and utilization of decommissioned ammunition is an urgent problem to be solved by the military. The invention is a fuze unscrewing device developed for the disassembly of small-caliber shells. The disassembly of small-caliber shells is generally divided into steps such as primer removal, fuze removal, separation of cartridge and combat part, propellant pouring and collection, among which fuze removal is the most important step in the disassembly process, which is directly related to disassembly. sub-process security. Usually, the fuze of the small-caliber projectile and the warhead are connected by threads, and th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F42B33/06

Inventor 赖利国高君张云贺于赢张欲立孟凡军何毅李健白贺飞

Owner CHANGCHUN EQUIP TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com