Energy-saving anti-freezing dry and wet type air cooler

A dry-wet, air-cooler technology, applied in heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problems of large floor space, affecting heat exchange effect, poor heat exchange performance, etc., to save space. The effect of reducing the ground area, suppressing the formation of the fluid boundary layer, and improving the heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

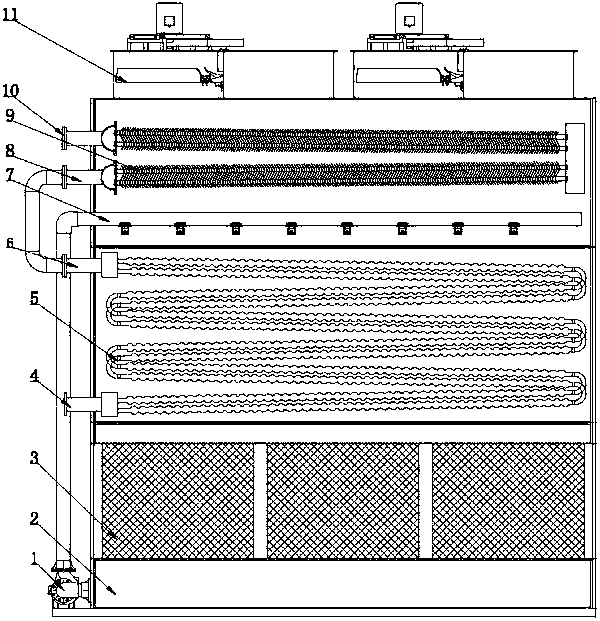

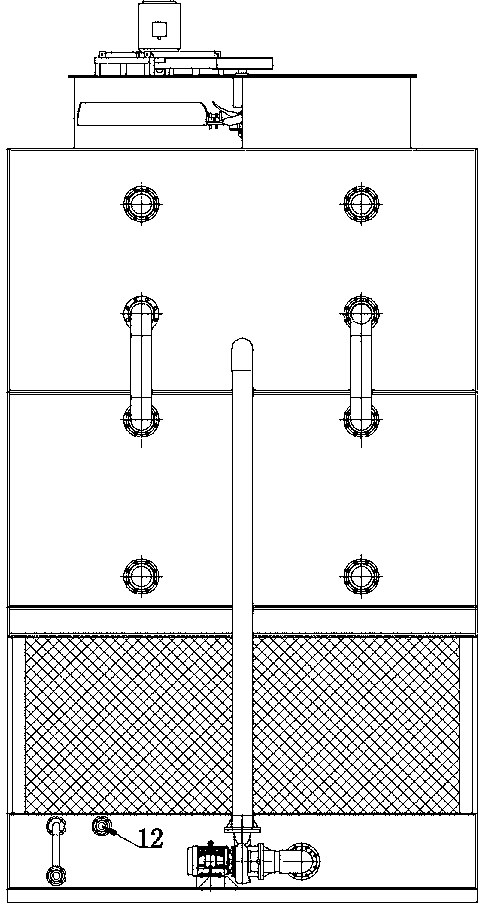

[0019] Such as figure 1 and figure 2 The energy-saving antifreeze type dry and wet air cooler shown in the figure includes a spray circulating water tank 2 with a water replenishment port 12, an air inlet grille 3, a wet cooling section cooler 5, a spray system 7, The dry cooling section cooler 9, the pneumatic system 11, the spray circulating water tank 2 is connected with the spray system 7 through the spray pump 1 and the water pipe, the wet cooling section cooler 5 is provided with a cold medium outlet 4 and a medium temperature medium inlet 6, and the dry cooling section is cooled The device 9 is provided with a medium-temperature medium outlet 8 and a high-temperature medium inlet 10, and the medium-temperature medium outlet 8 is connected with the medium-temperature medium inlet 6 through a pipeline.

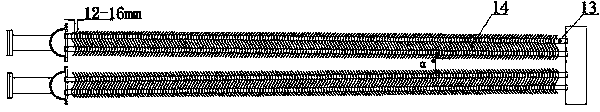

[0020] Such as image 3 As shown, the dry cooling sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com