Plate-type evaporation air-cooling condenser

An air-cooled condenser and plate evaporation technology, which is applied in the field of heat exchange, can solve the problems of poor adaptability to working conditions, low heat exchange efficiency, and large floor space, etc., to reduce floor space, improve efficiency, and save circulating cooling water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be further described below in conjunction with the drawings and embodiments.

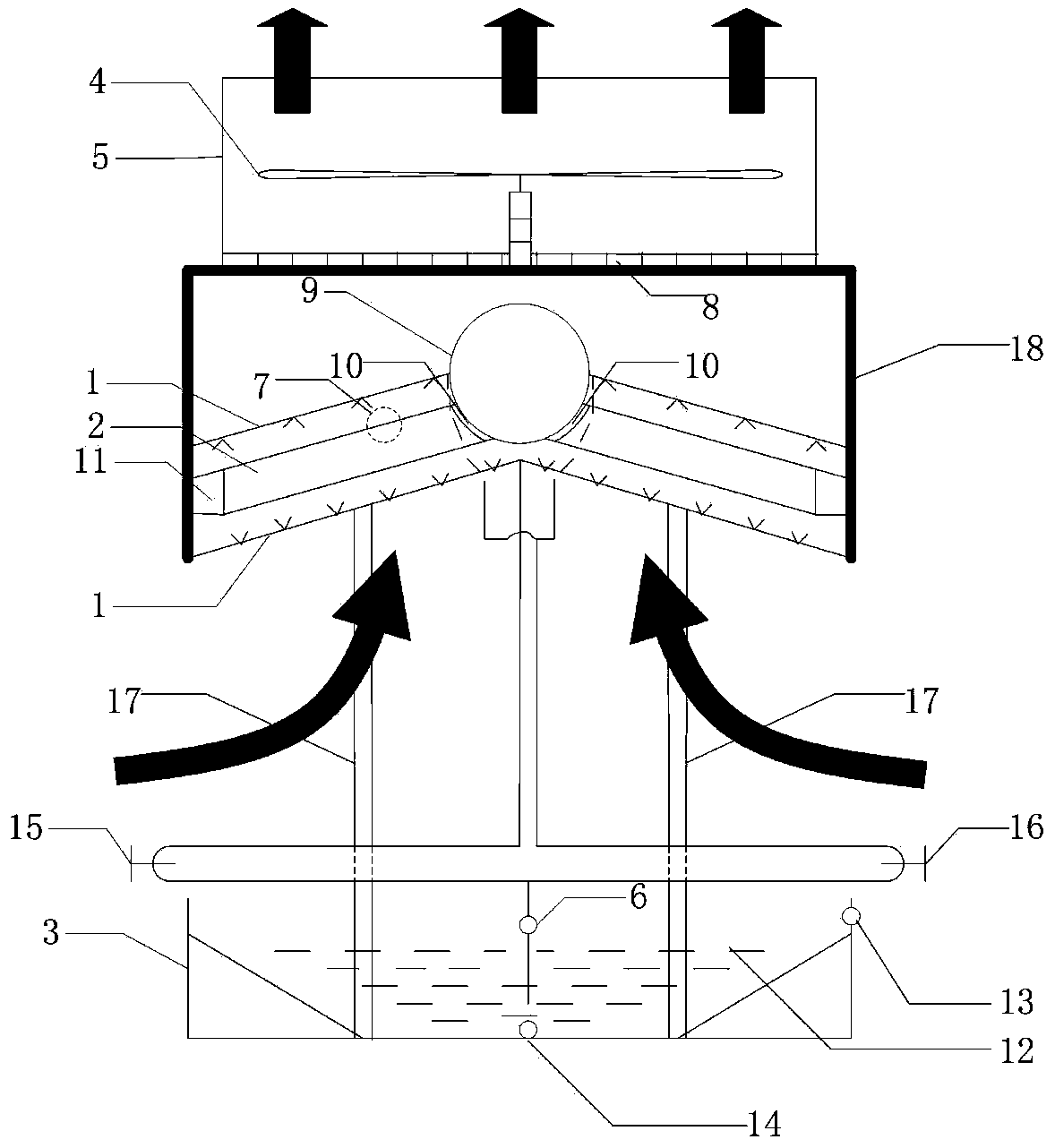

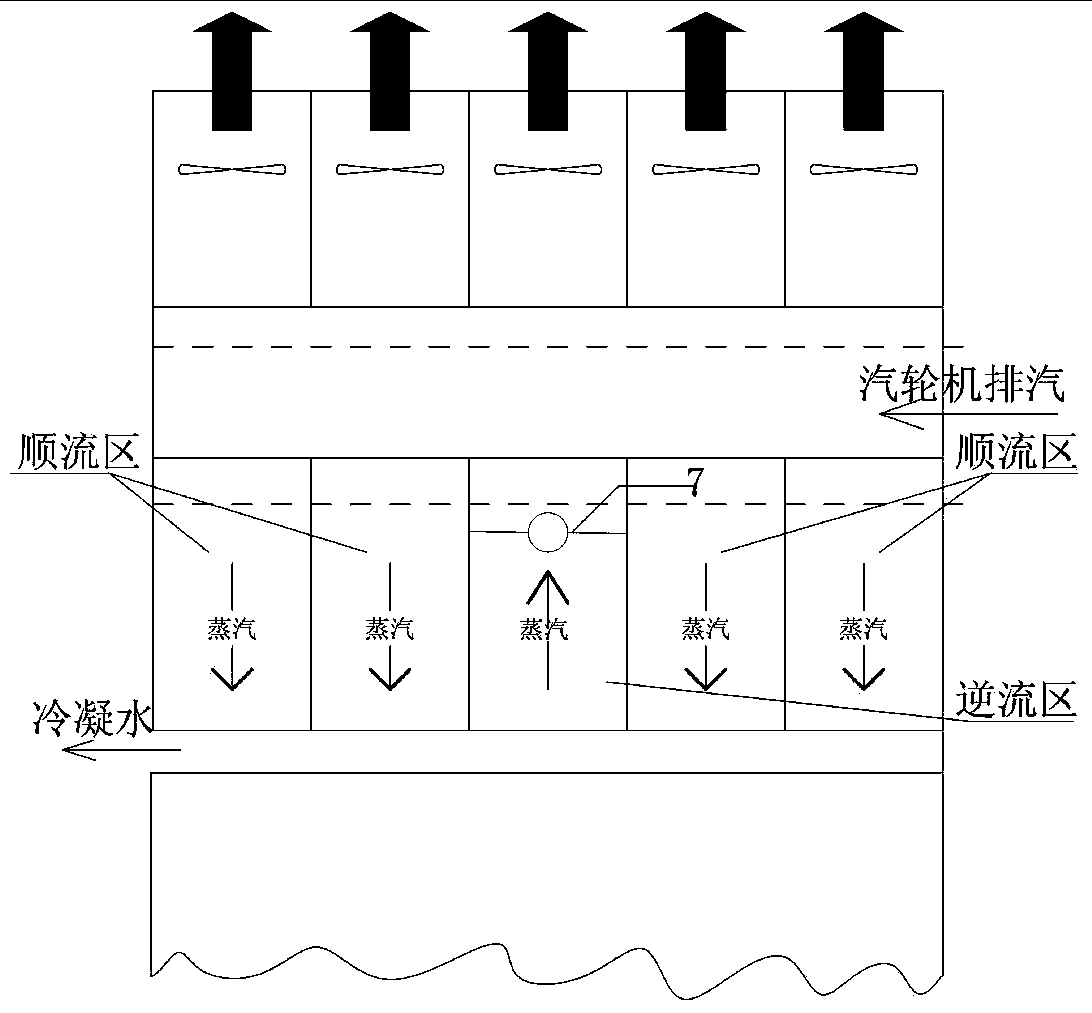

[0021] A plate-type evaporative air-cooled condenser proposed by the present invention comprises, from top to bottom: an air outlet tube 5, a fan 4, a water baffle 8, a frame 18, a steam distribution pipe 9, a spray device 1, and a steam inlet 10 , water ring vacuum pump 7, heat exchange plate bundle 2, condensed water outlet 11, pillar 17, regulating valve 1 15, regulating valve 2 16, water supply port 13, circulating water pump 6, water storage tank 12, box body 3, sewage outlet 14;

[0022] Wherein, the air outlet tube 5 is located above the frame 18, and its diameter is slightly smaller than the width of the frame, and the blower fan 4 is located in the air outlet tube 5, in order to avoid backflow of hot air and form a uniform air flow field in the box body 3; It is arranged under the fan 4 to block the water droplets conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com