Dehumidifying device of heat pump

A heat pump dehumidification and regenerator technology, applied in the field of heat pumps, can solve the problems of increasing the wind speed of the drying system, complicated installation, and large compression ratio of the compressor, so as to achieve the effects of increasing the air volume of the condenser, improving the dehumidification performance, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

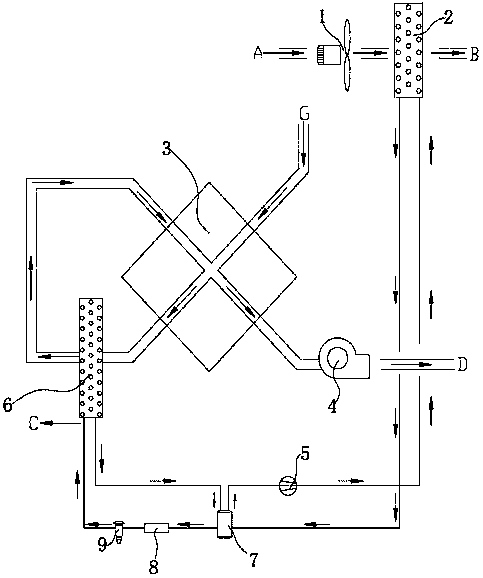

[0029] Heat pump dehumidifiers such as figure 1 As shown, it includes a refrigeration cycle, a dehumidification module and a circulating air module. The refrigeration cycle includes a first condenser 2, an evaporator 6, an expansion valve 9 and a compressor 5. The outlet of the compressor 5 is connected to the The inlet of the first condenser 2 is connected, the outlet of the first condenser 2 is connected with the inlet of the expansion valve 9 through a filter 8 through a copper pipe, and the outlet of the expansion valve 9 is connected with the inlet of the evaporator 6, so The outlet of the evaporator 6 is connected to the compressor 5 through a copper pipe to form a refrigeration cycle; the dehumidification module includes a regenerator 3 and a dehumidification fan 4, the hot side of the regenerator 3 is provided with an air inlet G, and the regenerator The hot side air outlet of heater 3 is connected with the cold side inlet of regenerator 3 through pipeline through evap...

Embodiment 2

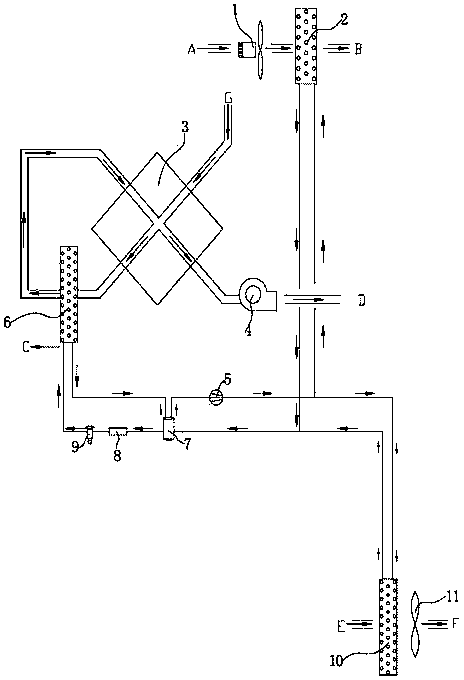

[0032] On the basis of the mechanism of Embodiment 1, the heat pump dehumidification device of the present invention also includes a second condenser 10, the outlet of the compressor 5 is connected to the inlet of the second condenser 10 through a pipeline, and the second condenser 10 The outlet of the evaporator 6 is connected to the inlet of the evaporator 6 through a filter 8 through a pipeline, the outlet of the expansion valve 9 is connected to the inlet of the evaporator 6, and the outlet of the evaporator 6 is connected to the compressor 5 through a pipeline to form an outdoor refrigeration cycle. A second circulating air module is arranged beside the second condenser 10 . The second circulating air module includes a second circulating fan 11 , and the second circulating fan 11 is installed beside the second condenser 10 . The air is output from the air outlet F of the second circulating fan 11 through the second condenser 10 through the inlet E, the air is cooled by th...

Embodiment 3

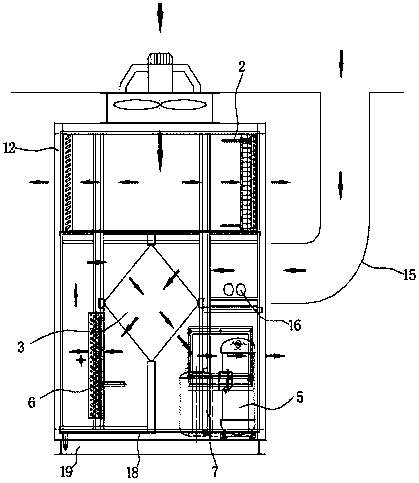

[0034] Such as Figure 7 with Figure 8As shown, wherein, the first condenser 2 or the second condenser 10 and the circulation fan or the second circulation fan 11 are installed in one body to form an independent module. The first condenser 2 or the second condenser 10 are respectively connected to the compressor 5 and the filter 8 through copper pipes 15; in this way, the installation is more flexible, can no longer be controlled by space, and the structure is more compact, and the heat exchange The efficiency is effectively improved, while reducing unit installation costs and saving installation space.

[0035] Wherein, the bracket 12 is made of profiled steel, sheet metal processing or aluminum alloy, which has a strong structure and saves cost. The outer shell adopts a composite insulation board with thermal insulation performance, which is not less than 25mm, and the inner layer of the composite board is a hot-dip galvanized steel plate, aluminum plate or stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com