Device for continuously preparing low dew point low temperature drying air

A technology for drying air and preparation equipment, which is applied in steam condensation, air conditioning systems, refrigeration and liquefaction, etc. It can solve the problems of difficult gas temperature constant, high production cost, and inability to effectively obtain low temperature and low dew point, so as to achieve low production cost and easy operation. Simple, good dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

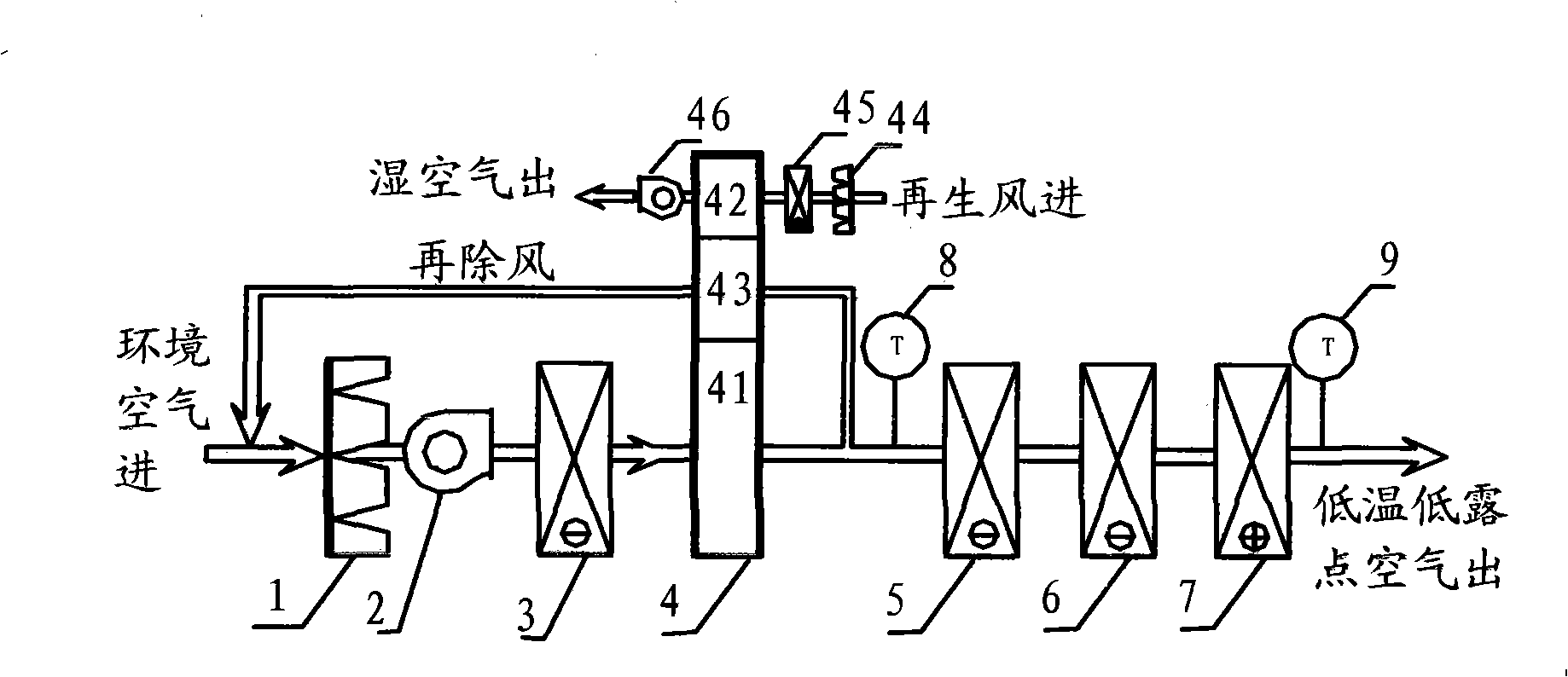

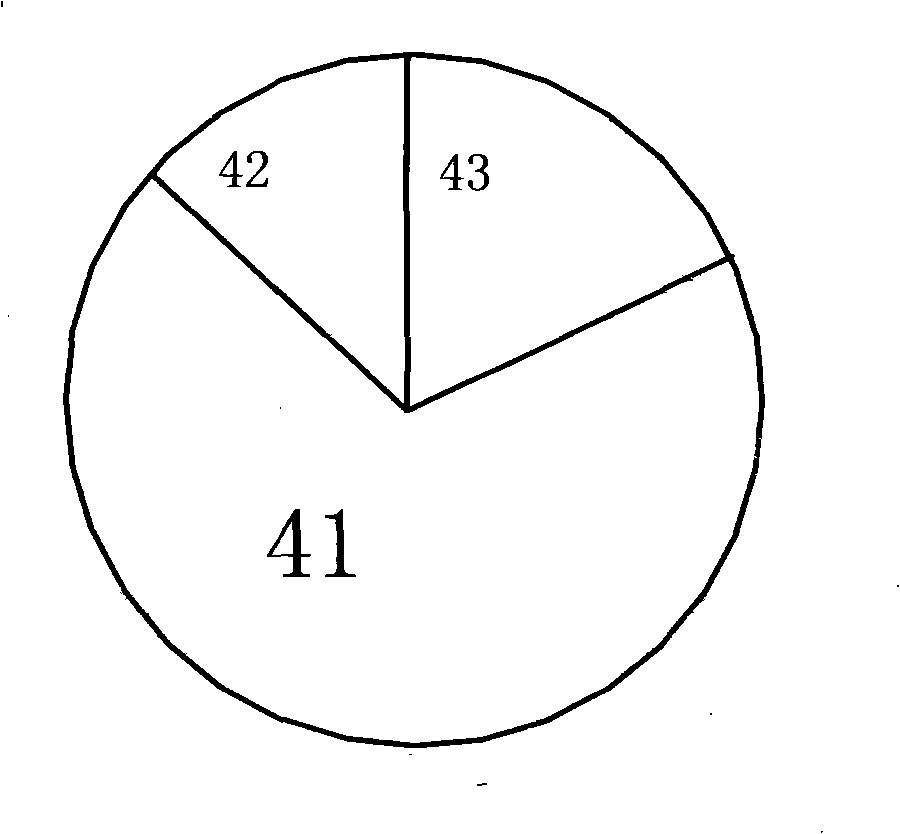

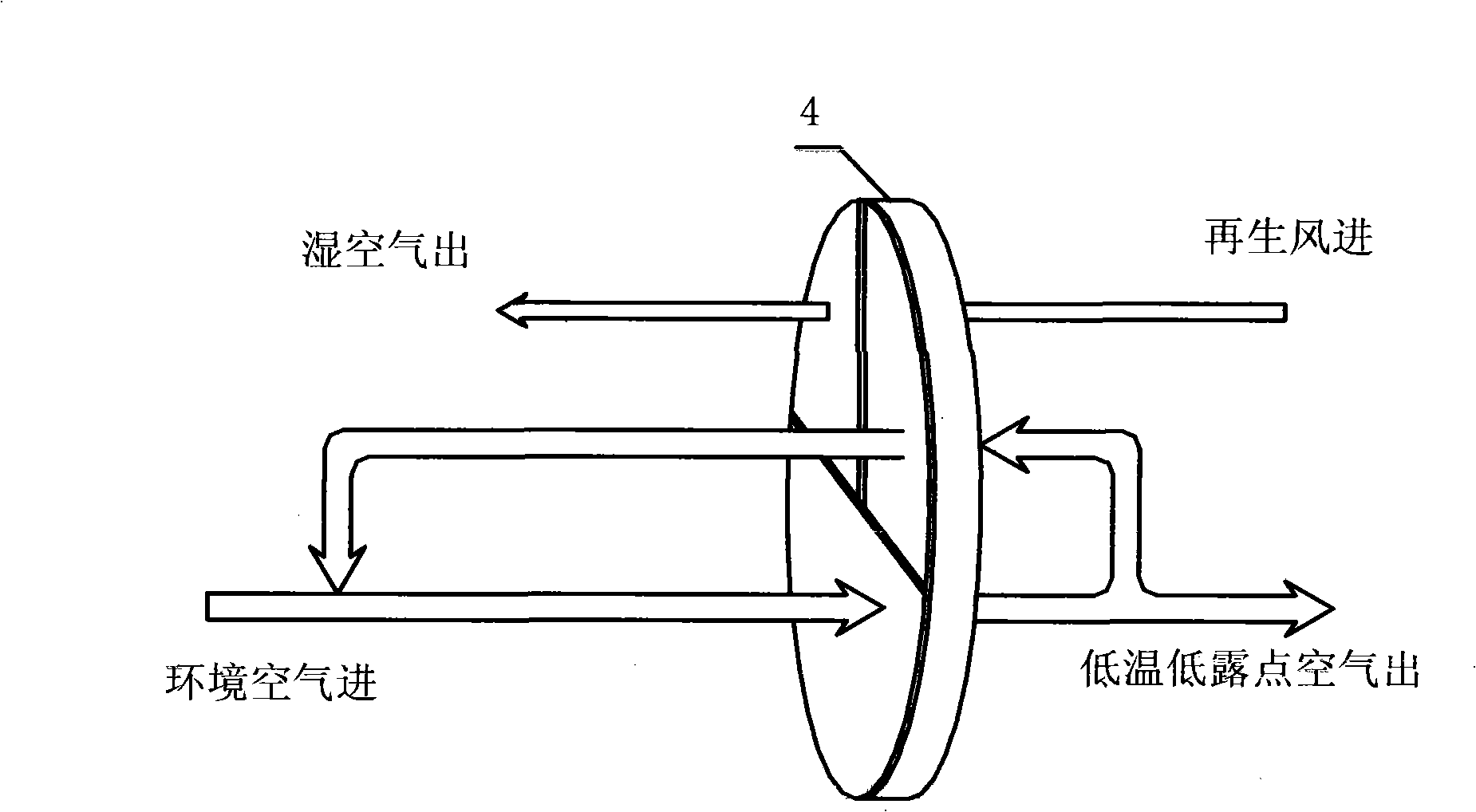

[0021] A continuous preparation device for low dew point low temperature dry air, mainly composed of the following parts: primary effect air filter 1, air induction device 2, primary surface refrigerant cooler 3, rotary dehumidifier 4, primary cryogenic refrigerant cooling 5, two-stage cryogenic refrigerant cooler 6, box body, a gas inlet is provided at the end of the box body, a gas outlet is provided at the tail of the box body, and primary effect air is arranged in sequence from the end to the tail of the box body Filter 1, air induction device 2, primary surface refrigerant cooler 3, rotary dehumidifier 4, primary cryogenic refrigerant cooler 5, secondary cryogenic refrigerant cooler 6, primary effect air filter 1 , air induction device 2, primary surface refrigerant cooler 3, rotary dehumidifier 4, primary cryogenic refrigerant cooler 5, and secondary cryogenic refrigerant cooler 6 are connected in series through the air duct in sequence. The ambient air at normal tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com