Deep dehydrating system device for natural gas and dehydrating method

A technology of deep dehydration and system installation, applied in separation methods, chemical instruments and methods, gas fuels, etc., can solve the problems of low purity of triethylene glycol and low dehydration depth of natural gas, achieve wide application range, reduce water vapor content, etc. The effect of pressure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

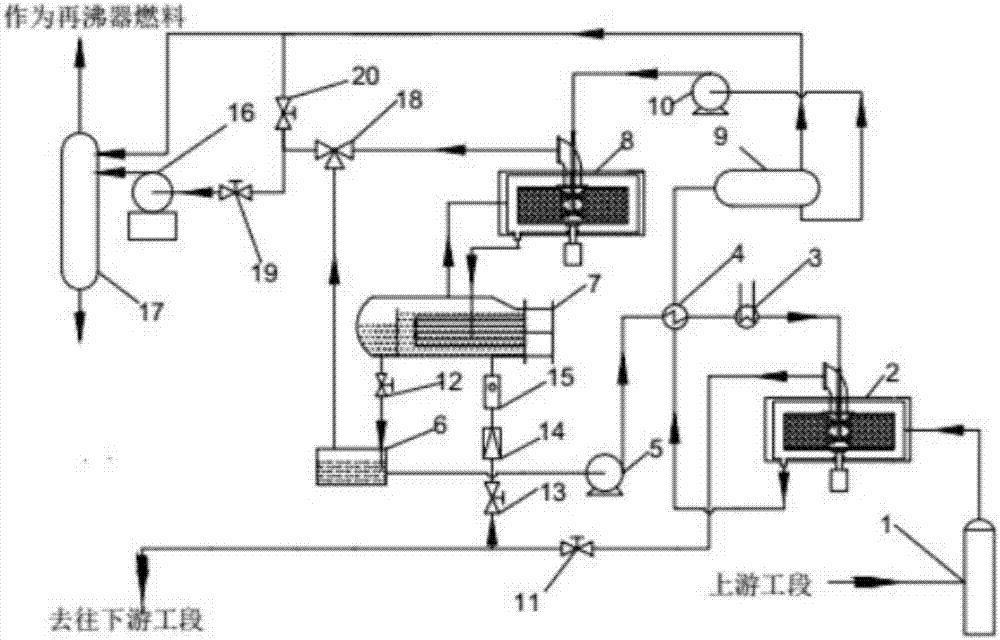

[0076] At the same time, adopt negative pressure enhanced regeneration and regeneration gas enhanced regeneration methods, use the above-mentioned device and process to remove water from natural gas with triethylene glycol: open the third stop valve 13, the fourth stop valve 19, and close the fifth stop valve 20.

[0077] The pressure of natural gas entering the system is 7MPa, the volume ratio of regeneration gas to product gas is 1:2000, the volume ratio of triethylene glycol lean liquid to natural gas raw material gas is 1:10000, and the supergravity level of No. 1 supergravity machine is 200, the supergravity level of the No. 2 supergravity machine is 200, the vacuum degree is 80kPa, the reboiler temperature is 190℃, and the condenser temperature is 30℃. Under this process condition, the purity of the triethylene glycol lean liquid after regeneration reaches about 99.99wt%, and the water dew point of the exported natural gas reaches below -50°C.

Embodiment 2

[0079] As described in Example 1, other conditions remain unchanged, the supergravity level of the first supergravity machine is adjusted to 100, after this process, the purity of triethylene glycol lean liquid after regeneration reaches about 99.99wt%, and the dew point of natural gas water reaches Below -48°C.

Embodiment 3

[0081] As described in Example 1, other conditions remain unchanged, the supergravity level of the first supergravity machine is adjusted to 20, after this process, the purity of triethylene glycol lean liquid after regeneration reaches about 99.99wt%, and the dew point of natural gas water reaches Below -28°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com