Dewatering method for glycol production process

A production process, ethylene glycol technology, applied in the chemical industry, can solve the problems affecting the production cost of ethylene glycol, long production process, energy and water consumption, etc., and achieve the effect of long service life, short process and high dehydration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

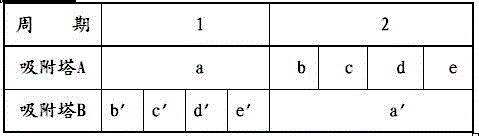

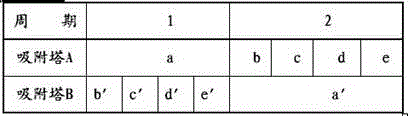

[0049] A kind of dehydration method in the ethylene glycol production process, the working process of its adsorption tower A and adsorption tower B comprises the following steps:

[0050] a', the raw material ethylene glycol solution is vaporized by the vaporization superheater, and after being heated by the heater, the valve V102 is opened to allow the ethylene glycol vapor to pass through the adsorption tower B from top to bottom through the valve KC05, and the room temperature and adsorption pressure in the adsorption tower B Under the condition of 0.1Mpa, the adsorption is carried out on the molecular sieve bed for 3-10 minutes; the gas after adsorption is condensed through the one-way valve V108 and the condenser, and then discharged, and the gas after the adsorption can get 99.5% ( For ethylene glycol above V / V%), after the adsorption is completed, close the valve KC05, stop feeding the raw material gas, and heat and vaporize at a temperature of 150-170°C.

[0051] ...

Embodiment 2

[0064] A kind of dehydration method in the ethylene glycol production process, the working process of its adsorption tower A and adsorption tower B comprises the following steps:

[0065] The raw material ethylene glycol solution is vaporized by the vaporization superheater, and after being heated by the heater, the valve V102 is opened, so that the ethylene glycol vapor passes through the valve KC05 and passes through the adsorption tower B from top to bottom. The normal temperature and adsorption pressure in the adsorption tower B are 0.1Mpa Adsorption is carried out on the molecular sieve bed for 8 minutes under certain conditions; the adsorbed gas is condensed through the one-way valve V108 and the condenser, and then discharged, and the adsorbed gas can obtain 99.5% (V / V%) after passing through the condenser After the above ethylene glycol is adsorbed, close the valve KC05 and stop feeding the raw material gas.

[0066] a. Adsorption: The raw material ethylene glyco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com