Soil strength detection sensor

A sensor and strength technology, applied in the field of sensors, can solve the problems of rough classification of tunnel surrounding rock, easy damage, inconvenient operation, etc., and achieve the effect of speeding up the detection operation speed, uniform expansion or contraction, and convenient detection operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

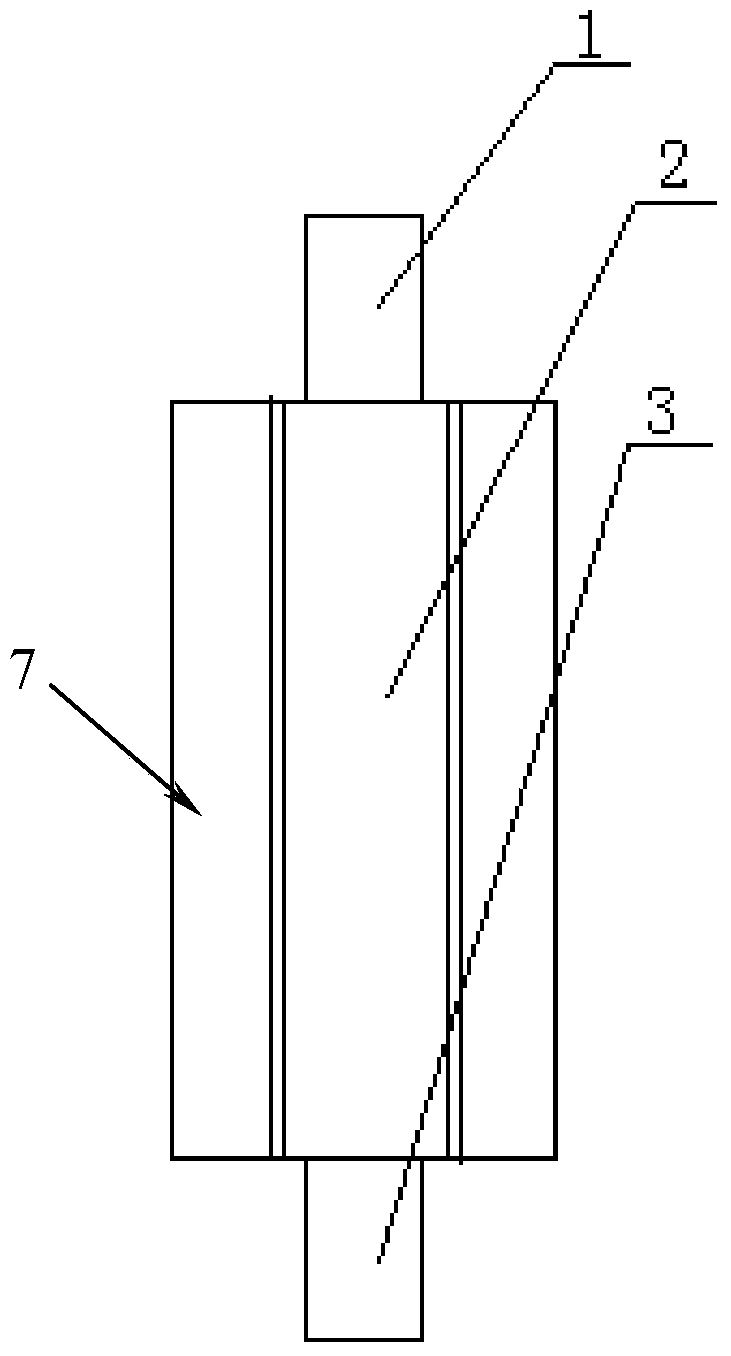

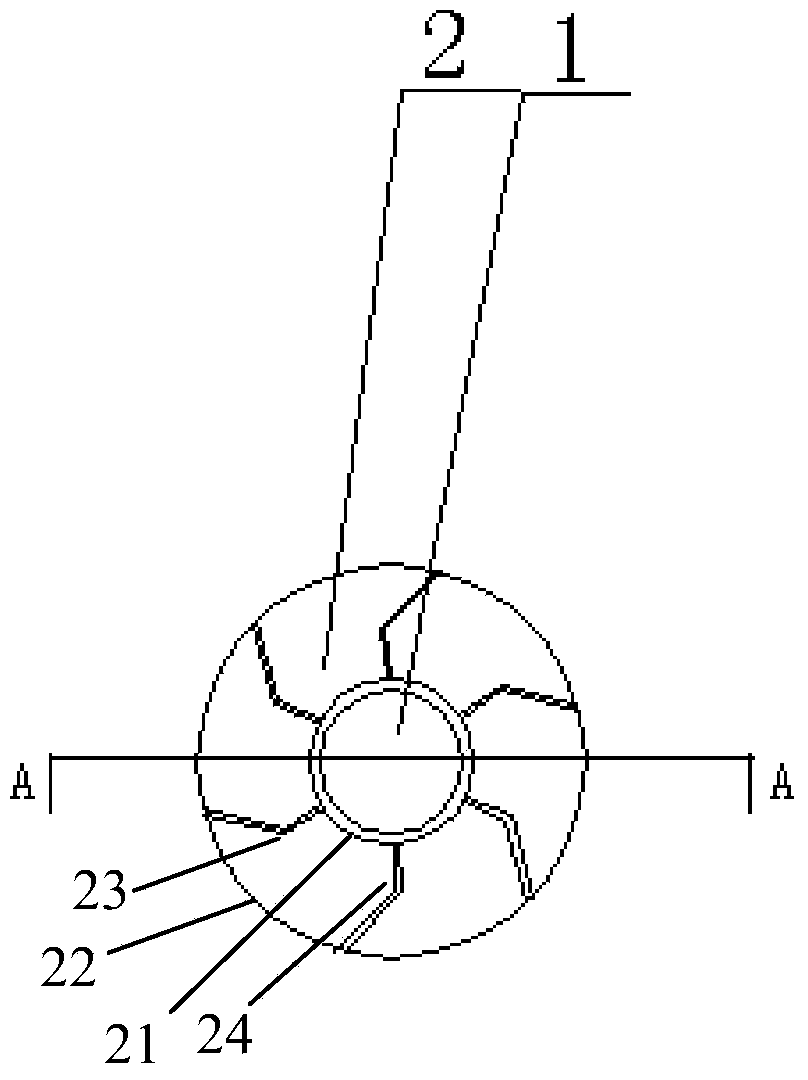

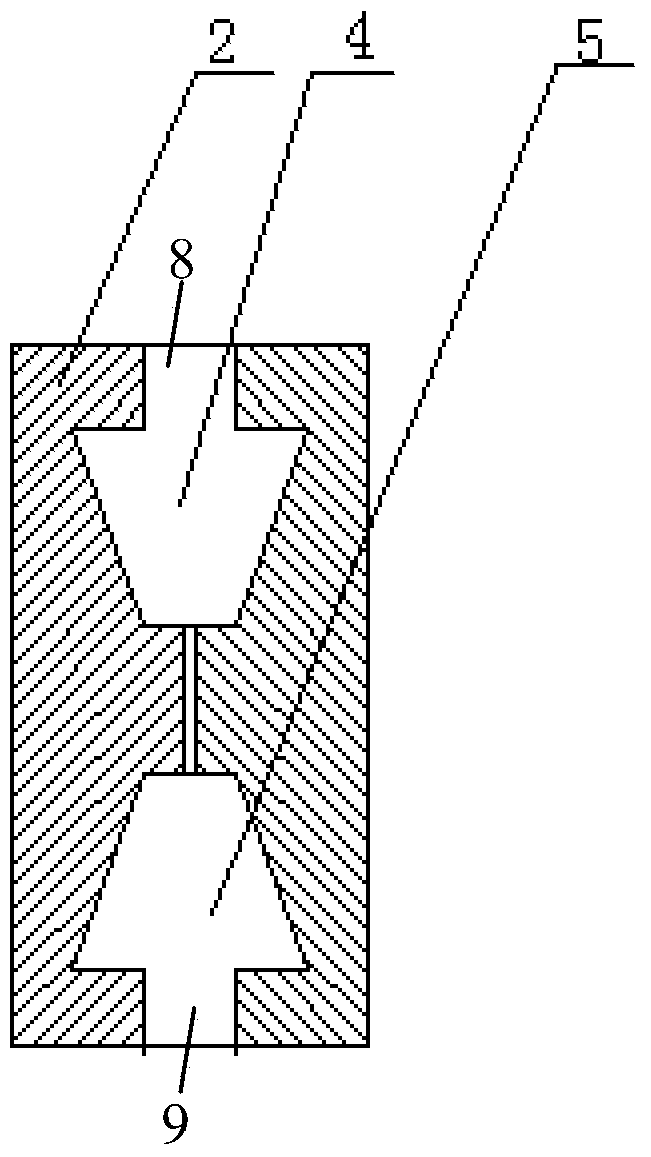

[0019] like Figure 1~4 The shown soil strength detection sensor includes a first push rod 1, a second push rod 3 and a plurality of sensing strips 2 made of pressure-sensitive materials, each sensing strip 2 surrounds a cylindrical expansion column 7, The top surface of the expansion column 7 is provided with a first sliding hole 8 downwards, and the expansion column 7 at the lower end of the first sliding hole 8 is provided with a first movable chamber 4, which is conical; the bottom surface of the expansion column 7 A second sliding hole 9 is opened upward, and a second movable chamber 5 is provided in the expansion column 7 at the top of the second sliding hole 9, and the second movable chamber 5 is conical; one end of the first push rod 1 is inserted into the first movable chamber 4, and is provided with the first conical head 6 that slides with the chamber wall of the first movable chamber 4; A second conical head (not shown) for sliding engagement with the wall.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com