Low-conductivity flake graphene composite material, and preparation method and application thereof

A kind of technology of flake graphene and composite material, applied in low-conductive flake graphene composite material, its preparation and its application field, can solve the problems such as graphene cannot accelerate corrosion, coating spreading, etc., reach to improve spreading rate, improve corrosion resistance The effect of inhibiting chemical properties and electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

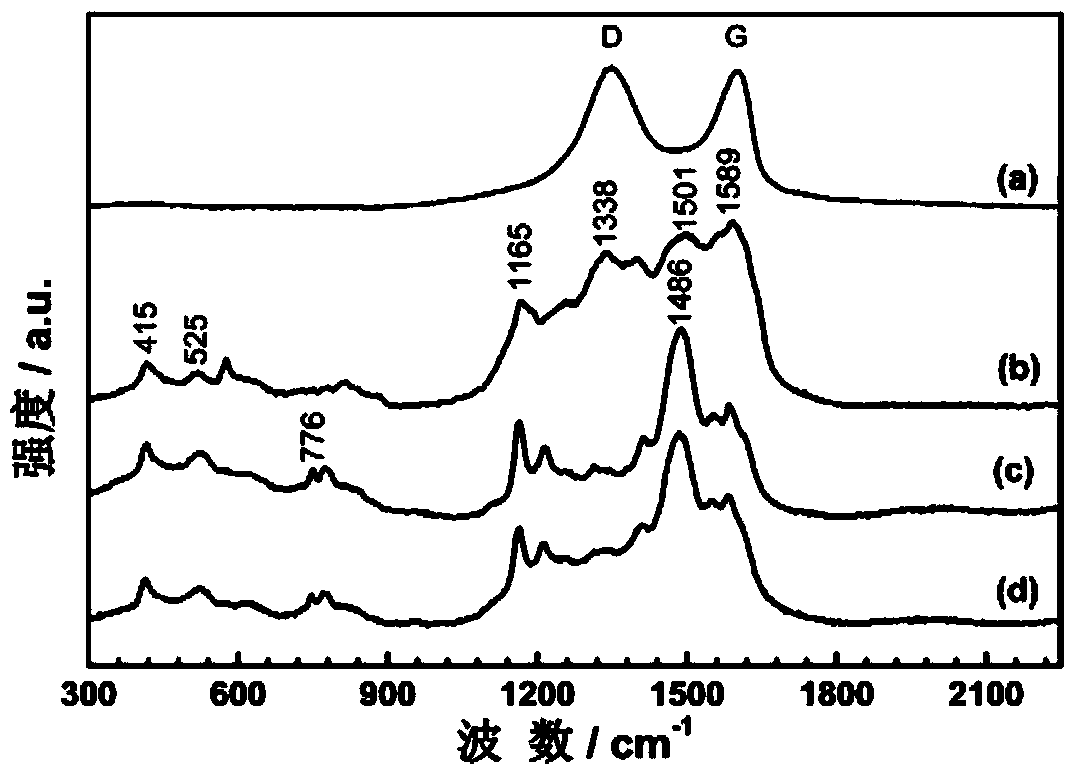

[0034] Step 1. Preparation of polyaniline / graphene oxide composite material: 0.36 g of graphene oxide was put into 180 mL of ethylene glycol, and the graphene oxide was completely peeled off by ultrasonication for 1 hour to form a graphene oxide dispersion. Slowly add 1 mL of aniline monomer to the dispersion, and form a stable single-layer graphene oxide / aniline dispersion under vigorous stirring. Thereafter, a solution prepared by 1.1 mL of concentrated HCl, 2.77 g of ammonium persulfate, and 20 mL of ethylene glycol was slowly added to the dispersion. The dispersion was polymerized in situ for 1 h under ice bath conditions. Finally, the resulting product was centrifuged and washed at least three times with deionized water to remove residual reactants.

[0035] Step 2. Preparation of the polyaniline / graphene composite material in an oxidized state with low conductivity flakes: the polyaniline / graphene oxide composite material prepared in step 1 was dispersed in 180 mL of de...

Embodiment 2

[0038] Step 1. Preparation of polyaniline / graphene oxide composite material: 0.3 g of graphene oxide was put into 180 mL of deionized water, and the graphene oxide was completely peeled off by ultrasonication for 2 hours to form a graphene oxide dispersion. Slowly add 0.5 mL of aniline monomer to the dispersion, and form a stable single-layer graphene oxide / aniline dispersion under vigorous stirring. Afterwards, a solution prepared by 1.1 mL of concentrated HCl, 2.77 g of ammonium persulfate, and 20 mL of deionized water was slowly added to the dispersion. The dispersion was polymerized in situ for 1 h under ice bath conditions. Finally, the resulting product was centrifuged and washed at least three times with deionized water to remove residual reactants.

[0039] Step 2. Preparation of the polyaniline / graphene composite material in an oxidized state with low conductivity flakes: the polyaniline / graphene oxide composite material prepared in step 1 was dispersed in 180 mL of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com