Wind-powered self-cleaning system for stagnant water lake

A self-cleaning, stagnant water technology, applied in the field of water cleaning systems, can solve the problems of difficult professional operation requirements, high input costs, and high consumption costs, and achieve the effects of meeting the needs of water, being environmentally friendly, and improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

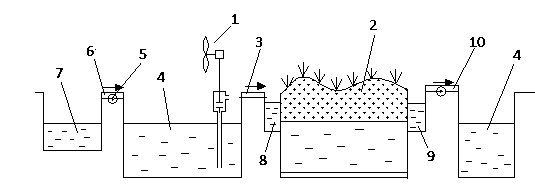

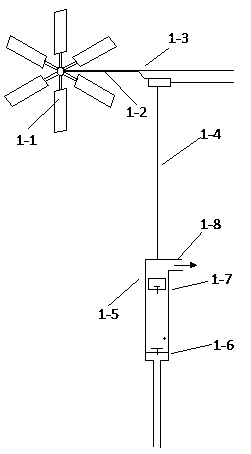

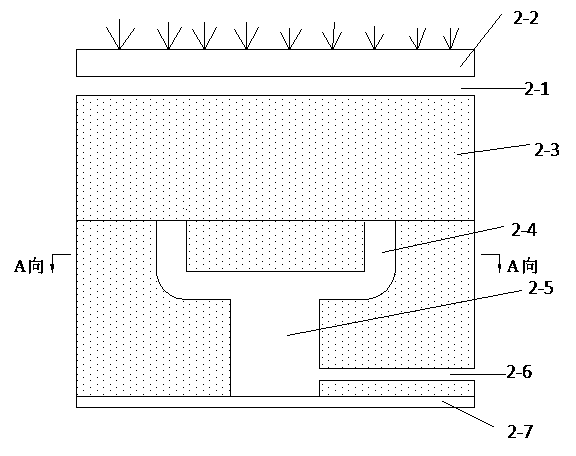

[0017] figure 1 It is a structural schematic diagram of the present invention, as can be seen from the figure, the bottom of the wind lifter 1 is inserted into the low place of the backwater lake 4, the impeller 1-1 and the piston pump 1-5 are located above the lake surface, and the water outlet 1-8 of the wind lifter 1 Connected to the water delivery pipe 3, the water delivery pipe 3 sends the water in the backwater lake 4 to the wetland treatment system 2, and the water in the backwater lake 4 is naturally purified in the wetland treatment system 2, and then discharged into the backwater lake 4 again, followed by Carry out to ensure that the water in the stagnant lake 4 can mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com