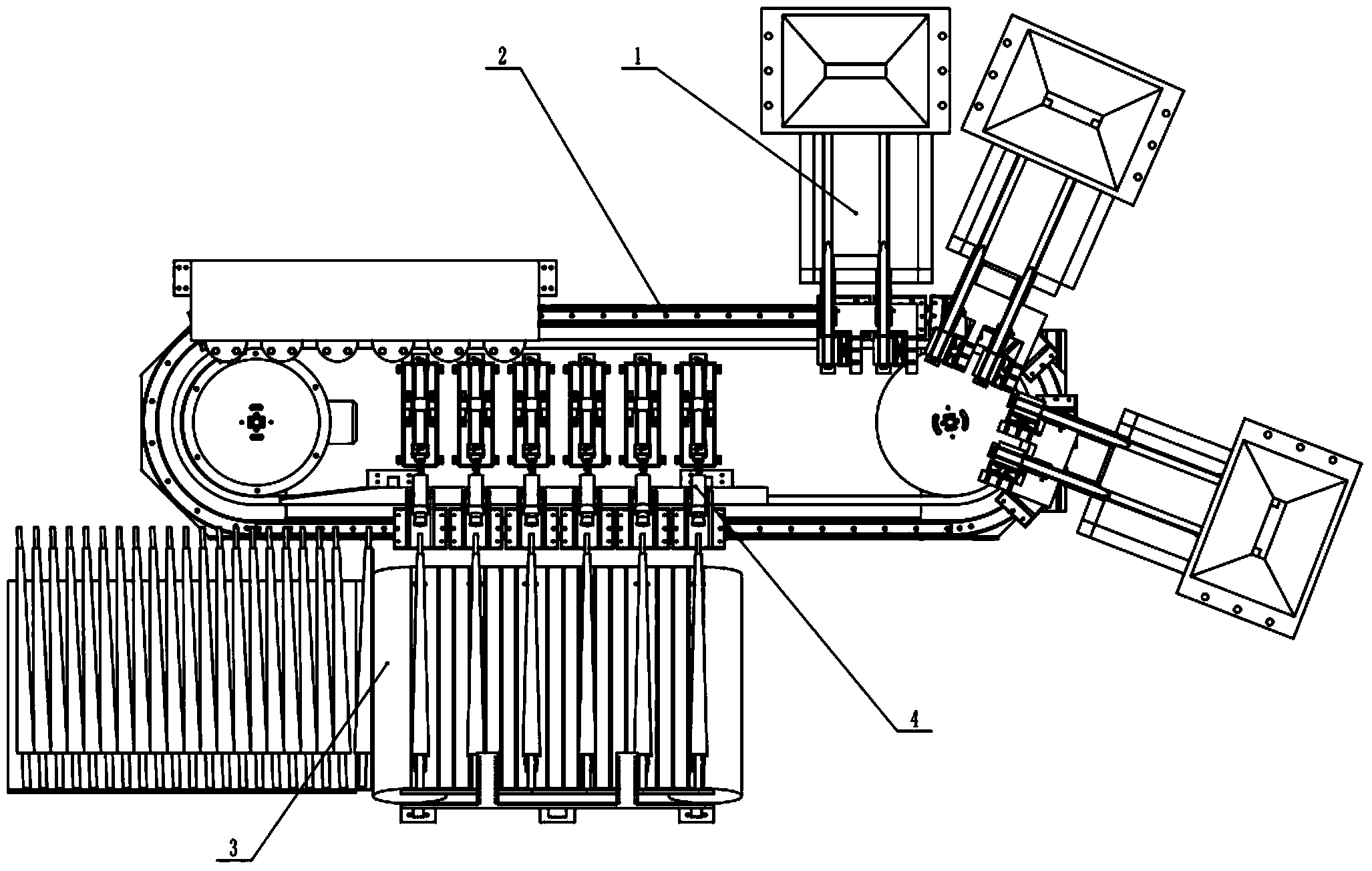

Automatic assembly line for umbrella tails of umbrellas

An automatic assembly and assembly line technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving efficiency, simple structure, and easy disassembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

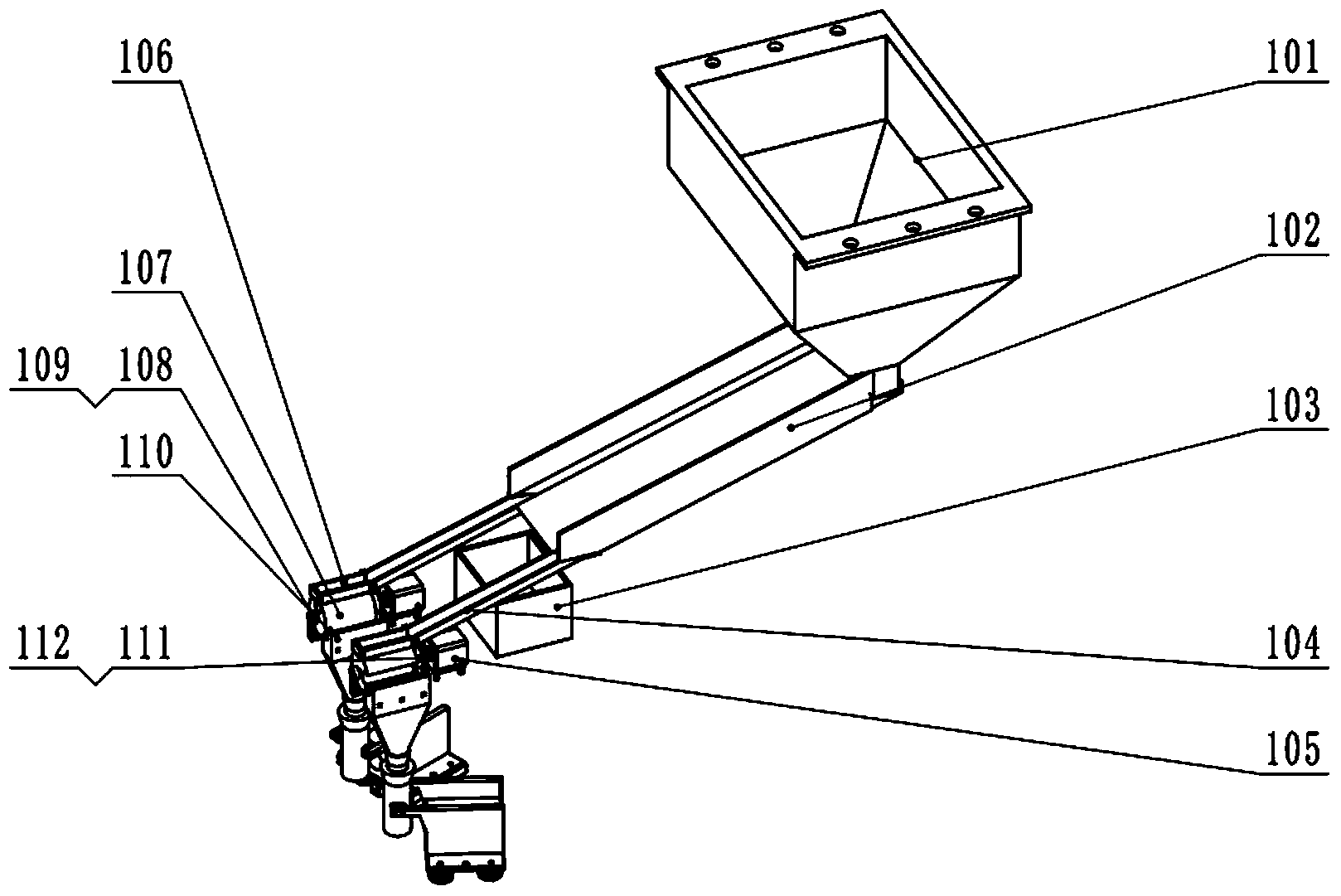

[0019] Utilizing the shape characteristics of the umbrella tail, a series of automatic devices are designed to realize the automatic feeding of the umbrella tail. The umbrella tail is dropped from the silo (101) to the screening slope (102). , when falling from the inclined plane, due to the effect of gravity, it will definitely deviate to both sides, so grooves are designed on both sides of the screening inclined plane and the ends are connected with arc-shaped feeding chute (103), and the end of the feeding chute (103) is connected with The material connection port (106) can make an umbrella tail stay here, and wait for the rotary material spacer (107) to transfer the umbrella tail to the turning material opening (110). Two pillars, the distance between the two pillars can make the small end of the umbrella tail pass and block the big end, so it is achieved that the big end port of the umbrella tail upwards falls into the reclaiming rotary head (201).

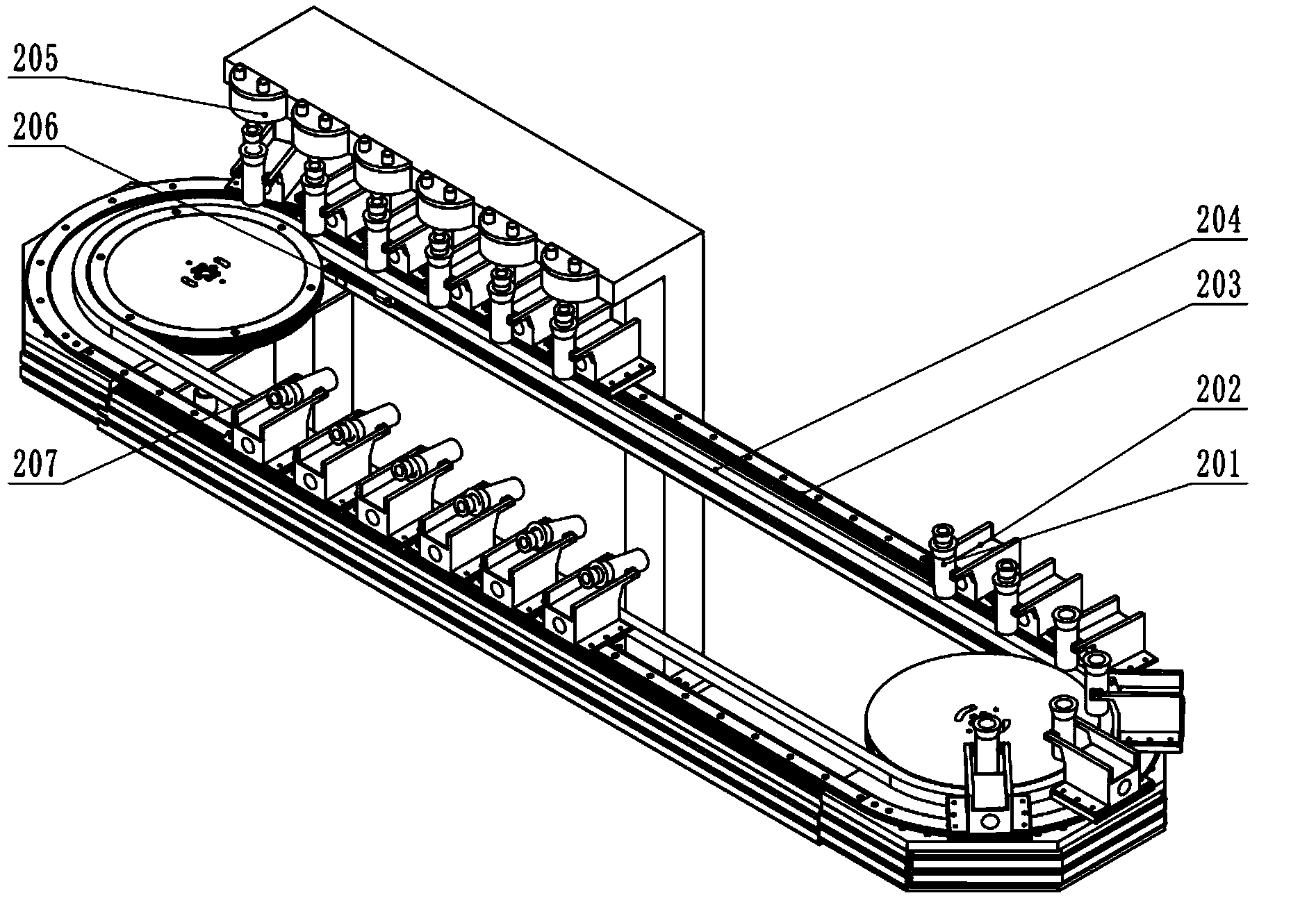

[0020] During the cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com