Paper shredding cutting tool and machining device and method thereof

A processing method and cutting tool technology, applied in the direction of grain processing, etc., can solve the problems of difficult helical arrangement of cutting edges, difficult to achieve firmness and strength, etc., to achieve simple processing methods, good usability and firmness, easy The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

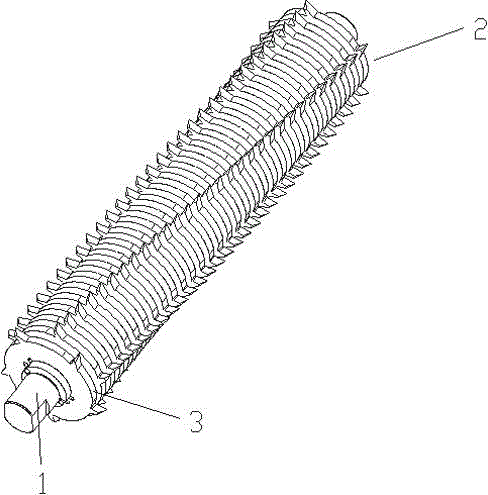

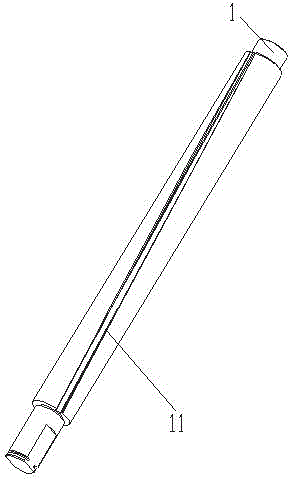

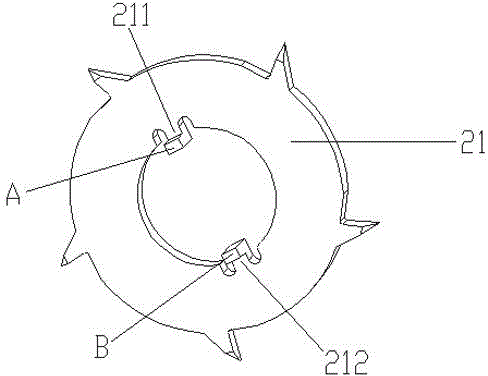

[0054] see figure 1 , a paper shredding cutter provided in this embodiment includes a cutter shaft 1 and a matching blade set 2; the blade set 2 includes a certain number of blades 21, and all the blades 21 are threaded on the cutter shaft 1 in a certain order, see figure 2 , the cutter shaft 1 is cylindrical, with two symmetrical spiral grooves on its surface (it can be seen that the spiral groove on one side is 11); see image 3 , the inner hole circumference of each blade 21 in the blade set 2 is provided with two protruding positioning ribs corresponding to the two spiral grooves of the cutter shaft 1, respectively recorded as 211, 212, and each positioning rib includes a height The protrusions that are beyond the plane of the blade body and can fit into the spiral groove of the cutter shaft 1 are respectively marked as A and B. These protrusions can be flatly assembled in the spiral groove of the cutter shaft 1 and passed It is firmly fixed in it after riveting. Prefe...

Embodiment 2

[0063] see Figure 9 , a paper shredding cutter provided in this embodiment, including a cutter shaft 1 and its matching blade set 2 and blade spacer ring 3, the cutter shaft 1 has two symmetrical spiral grooves on the surface (it can be seen that the spiral groove on one side is 11) Cylindrical cutter shaft for , see figure 2 , the inner holes of all the blades of the blade group 2 are circular, and the inner holes of all the blade spacer rings 3 are also circular, and the circumference of the inner holes of the blade spacer rings 3 are correspondingly provided with two spiral grooves that can be loaded into the cutter shaft. The protruding positioning ribs are recorded as 31 and 32 respectively. Preferably, the two protruding positioning ribs also protrude toward the outer circumference of the blade spacer ring 3 at the same time, see Figure 10 , the positioning ribs 31, 32 can be assembled in the corresponding spiral grooves of the cutter shaft 1, and firmly fixed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com