Noodle maker with safety switch

A safety switch, noodle machine technology, applied in the structural parts of mixing/kneading machinery, mixing/kneading with vertical installation tools, etc. Stability and other issues, to achieve the effect of small vibration, low noise, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

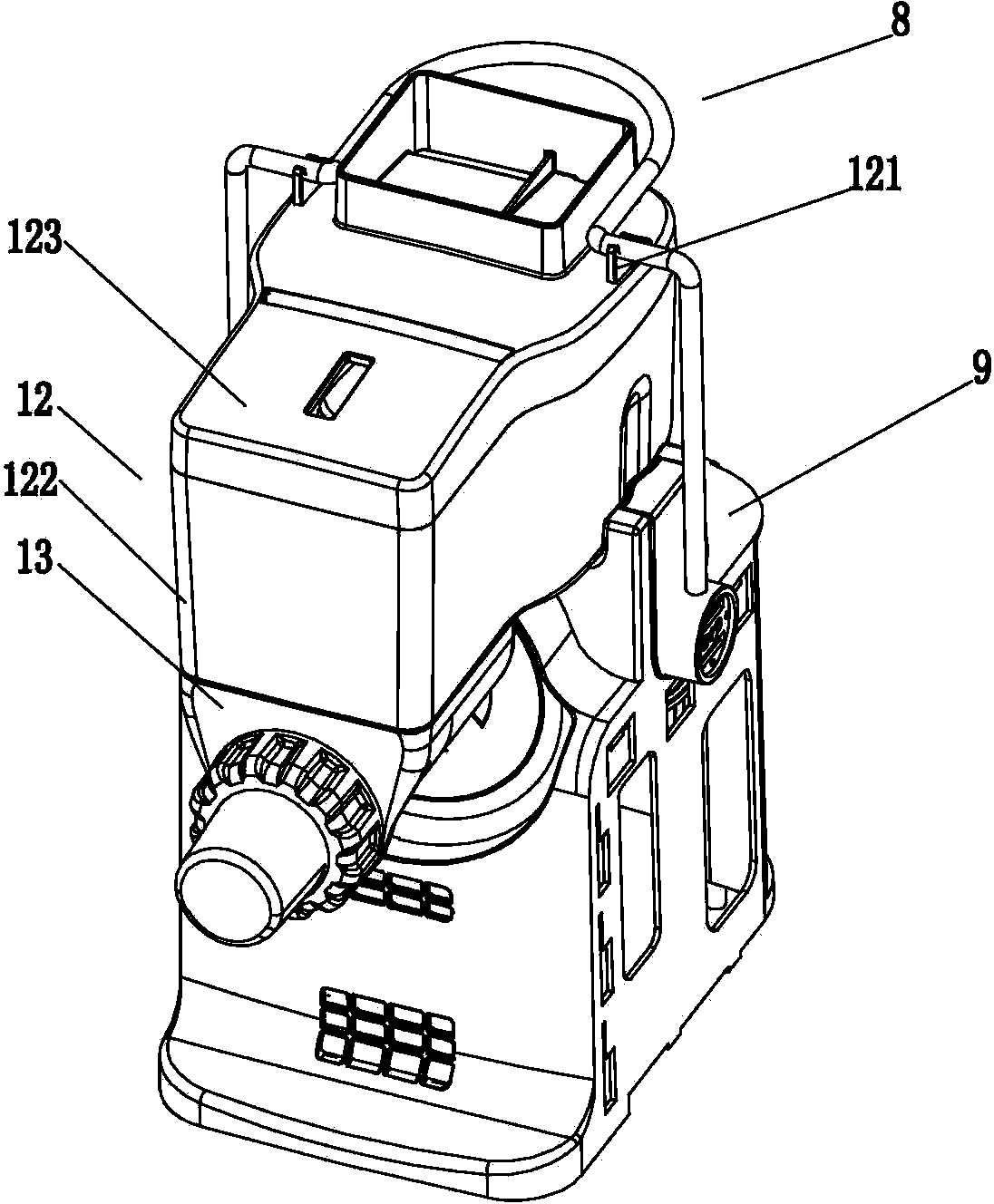

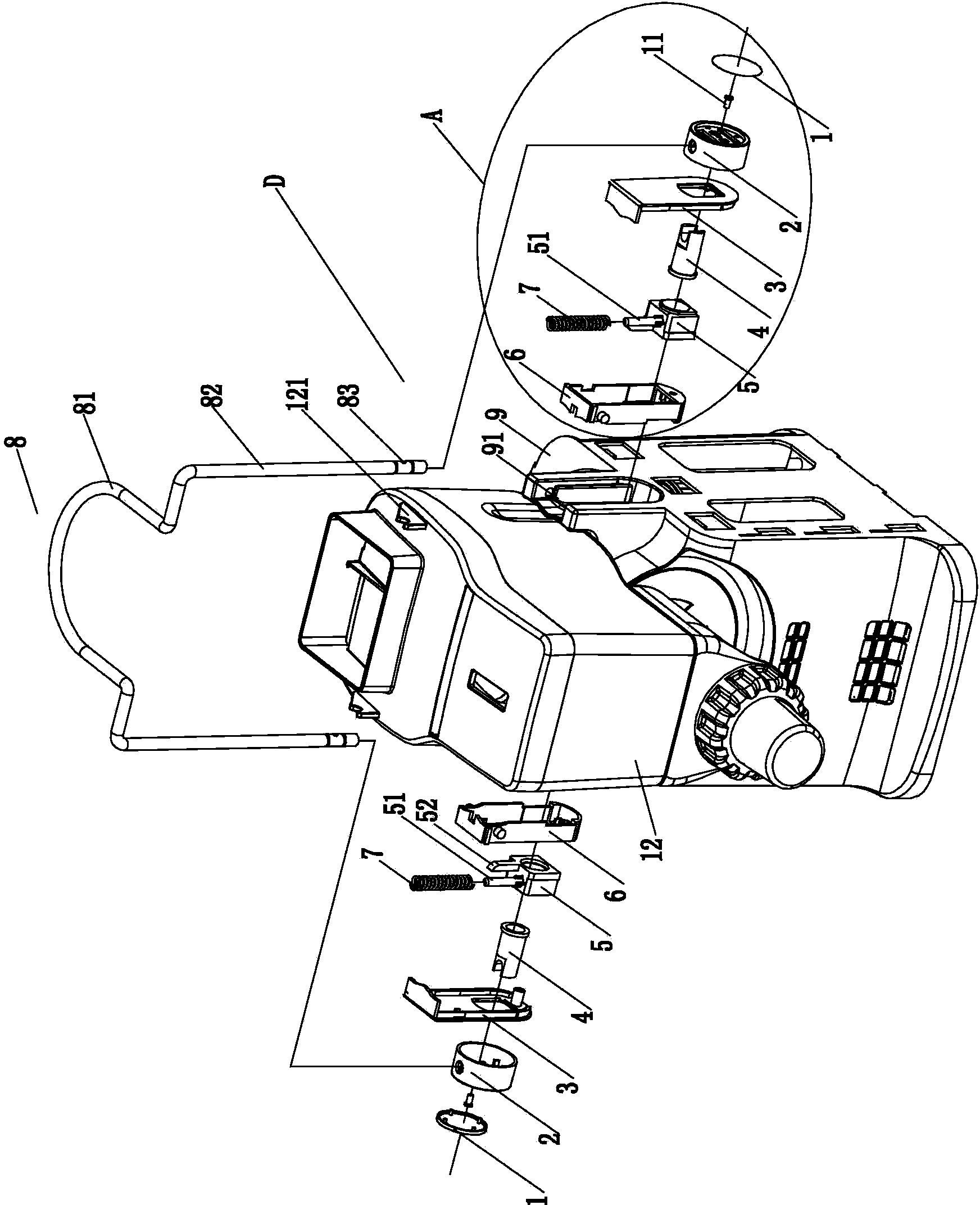

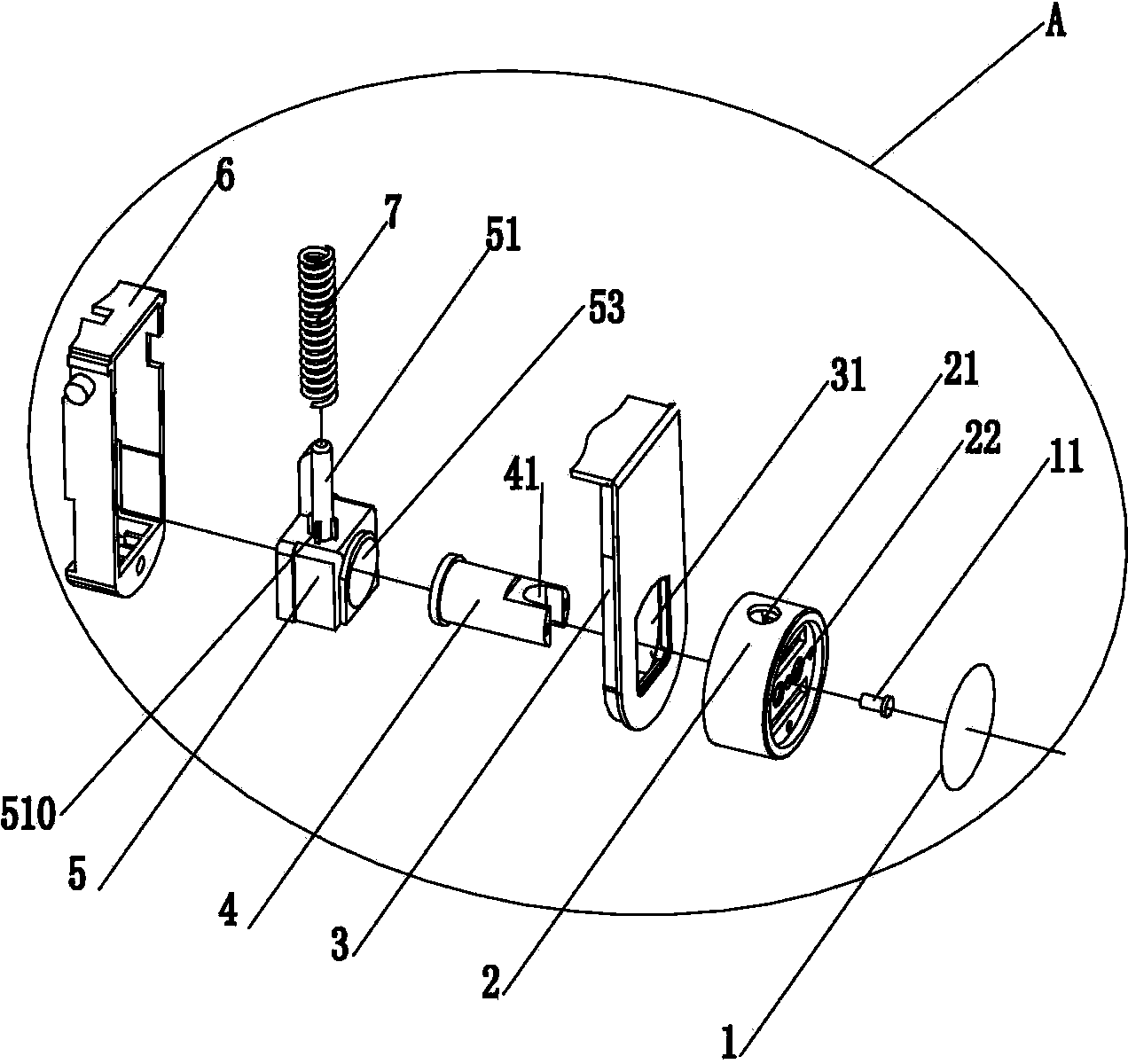

[0032] Example 1, such as Figure 1 to Figure 11 As shown, a noodle machine with a safety switch includes a body 9, and a kneading bucket 12 is arranged above the body 9, and the kneading bucket includes a bucket body 122, an electric stirring assembly 55 and a bucket cover 123, and the bucket cover is directly covered on the barrel body. The electric stirring assembly 55 includes a motor, a noodle-pressing screw, a stirring shaft, and a stirring plate. The front side of the body 9 is provided with a noodle pressing barrel 13 . Both sides of the body 9 are provided with movable handles D, which can press or move away from the bung 123 of the kneading bucket 12 by swinging. On the body next to the position of the movable handle D, A safety switch 10 is also installed, and the safety switch 10 is electrically connected in series with the electric stirring assembly 55, that is, the safety switch 10 is electrically connected in series with the motor.

[0033] As a novel and mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com