Design of cooling and tritium extracting loop for helium cooling solid state tritium multiplication covering layer multiplication unit

A cold circuit and tritium breeding technology, applied in nuclear reactors, nuclear power generation, climate sustainability, etc., can solve the problems of complex design of the tritium extraction circuit, and achieve the effect of increasing the space and integration of tritium breeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

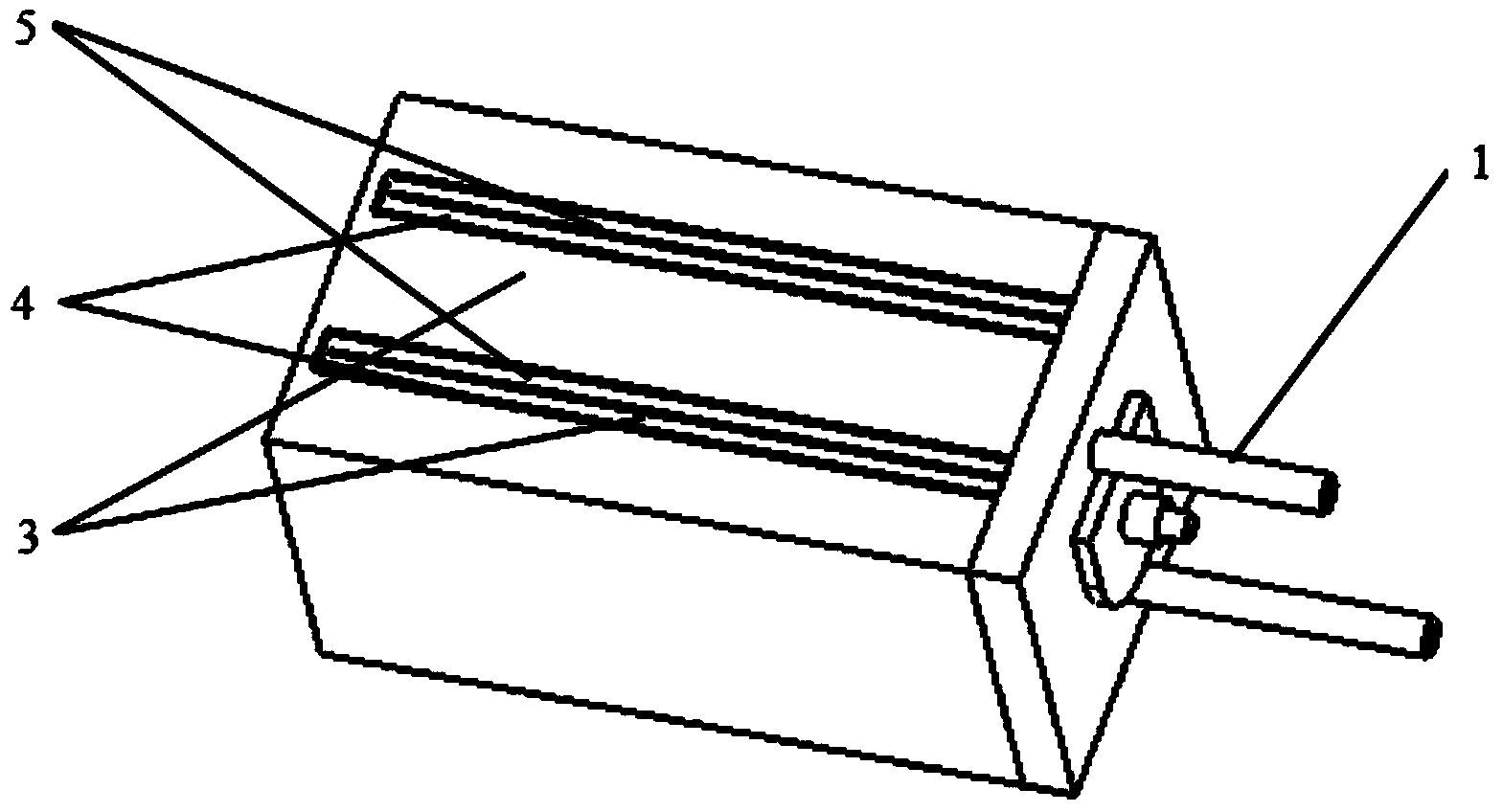

[0019] like figure 1 , 2 , 3, 4, 5, a cooling and tritium lifting circuit for the helium-cooled solid-state tritium breeding cladding breeding unit, including a pebble bed area 3 of the breeding unit, and two cooling plates 4, 5. One end of the pebble bed area 3 is equipped with a helium cooling circuit and a tritium lifting circuit. The helium cooling circuit includes a helium cooling circuit inlet 1, a distribution chamber 2, a manifold 6, a helium cooling circuit outlet 7, and a tritium lifting circuit. Including tritium extraction circuit inlet 8, distribution chamber 9, manifold 10, tritium extraction circuit outlet 11, helium cooling circuit inlet 1, distribution chamber 2, cooling plates 4, 5 and manifold 6, helium The air outlet 7 of the cold circuit is connected in sequence, the air inlet 8 of the tritium extraction circuit, the distribution chamber 9, the manifold chamber 10, and the air outlet 11 of the tritium extraction circuit are connected in sequence, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com