Duty ratio adjusting device of two-dimensional (2D) large-scale laser beam array

An adjustment device and large-scale technology, applied in optics, optical components, instruments, etc., can solve the problems of the theoretical limit of the output power of a single fiber laser, and achieve the effects of increased brightness, convenient adjustment, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

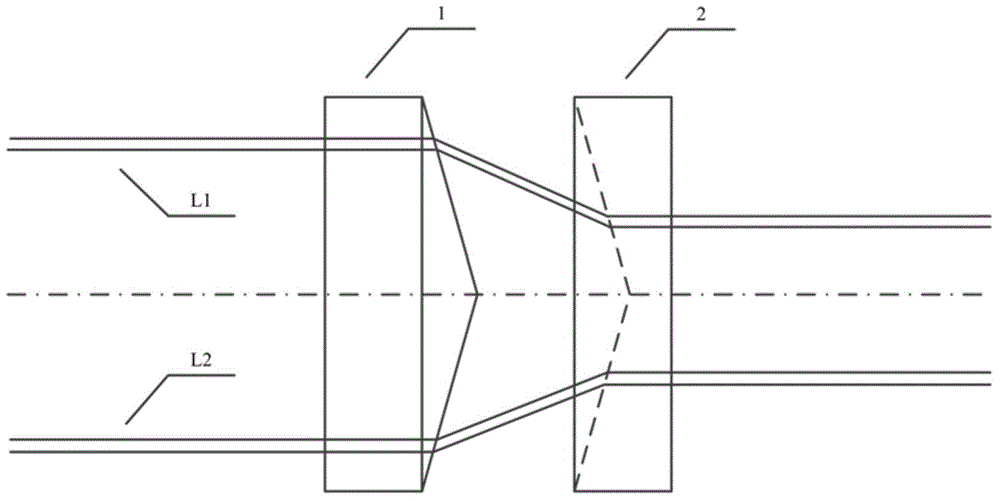

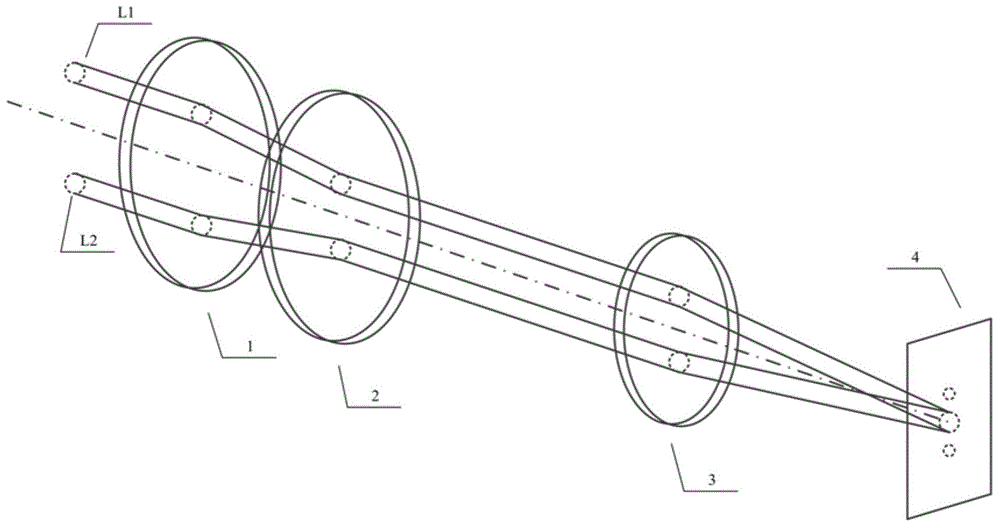

[0017] see first figure 1 , figure 1 It is a schematic diagram of a two-dimensional large-scale laser beam array duty ratio adjustment device of the present invention. As can be seen from the figure, the two-dimensional large-scale laser beam array duty ratio adjustment device of the present invention is composed of a coaxial convex corner cube 1 and a concave corner cube 2, the bottom surface of the convex corner cube 1, the convex corner cube The conical surface of the prism 1, the conical surface of the concave corner cube 2 and the bottom surface of the concave corner cube 2 are arranged in sequence along the optical axis, and the convex corner cube 1 or the concave corner cube 2 are placed in an adjustment device that moves along the optical axis. Institutional.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com