Reliability loading testing device and method for main shaft of numerically controlled lathe

A loading test device, loading device technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of lack of testing of spindle precision decline, easy loss of precision, spindle loading, etc., to achieve improvement Test efficiency and fault acquisition speed, scientific test method, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

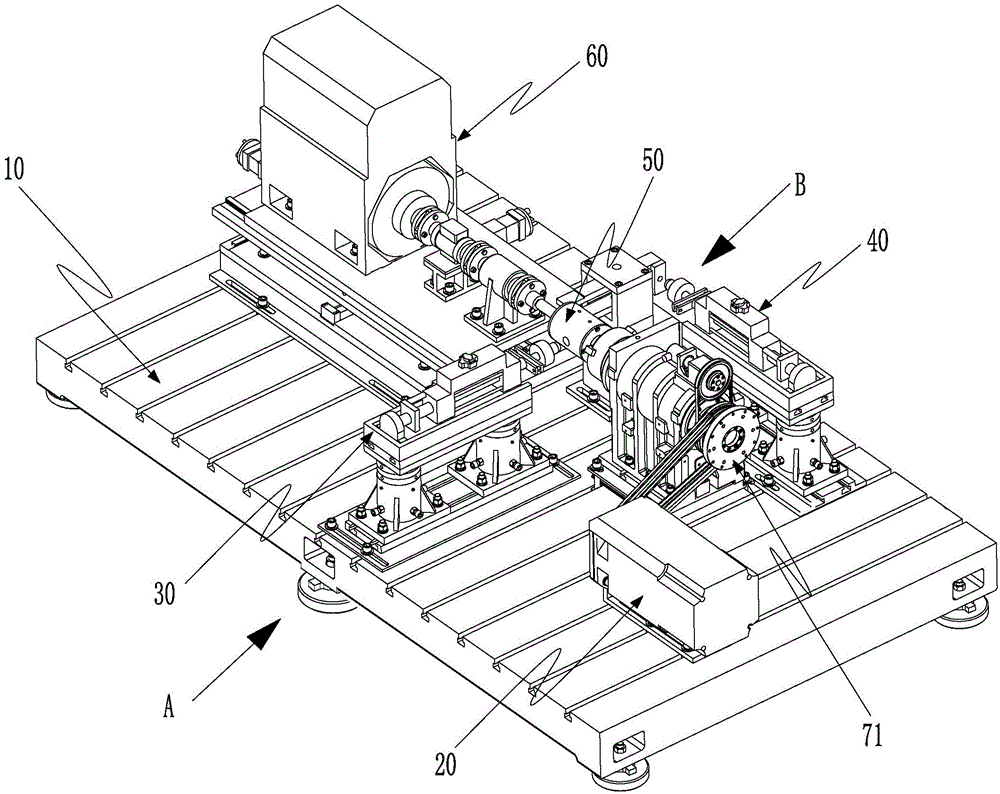

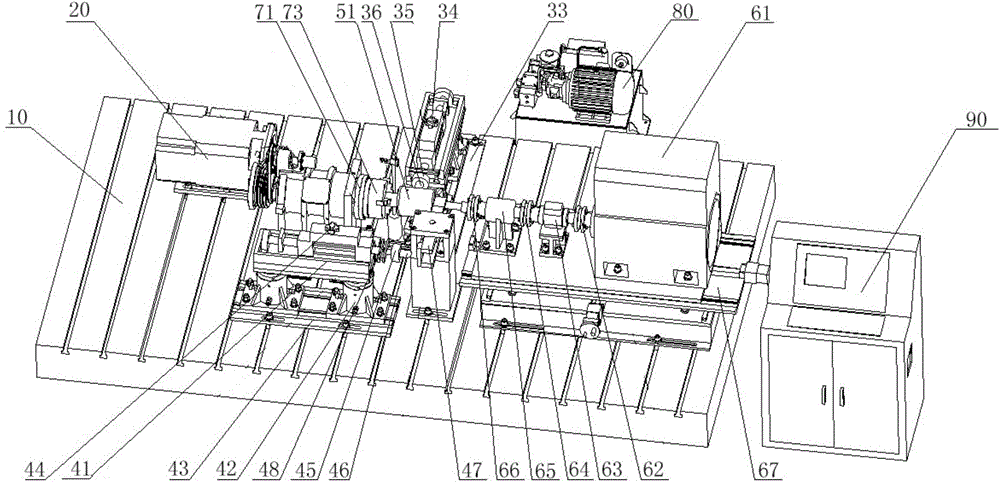

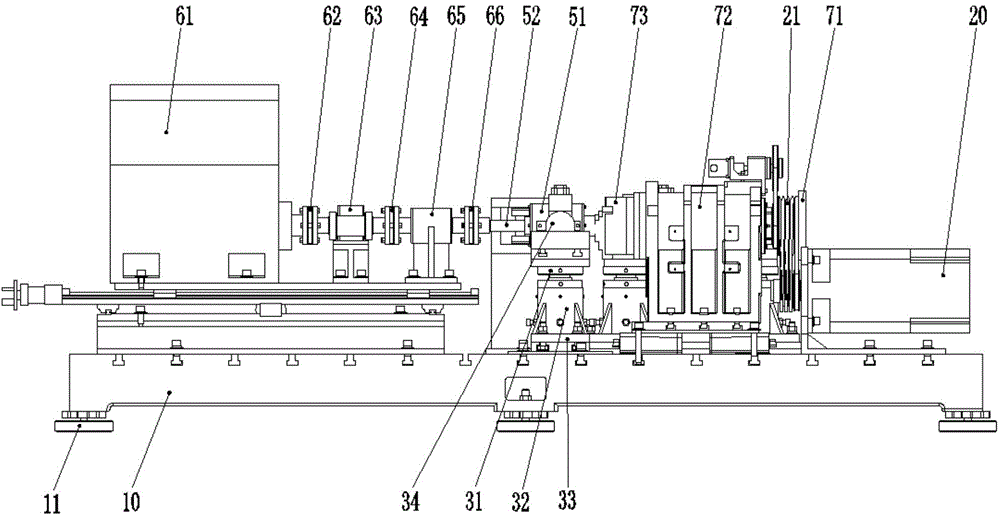

[0034] Example 1 A Reliability Loading Test Device for CNC Lathe Spindle

[0035] Such as Figure 1-Figure 6 As shown, a CNC lathe spindle reliability loading test device consists of a test bench body (10), a motor (20), a radial cutting force simulation loading device (30), an axial cutting force simulation loading device (40), a bearing It consists of a loading unit (50), a torque loading system (60), a hydraulic system (80) and a control system (90).

[0036] The motor (20), radial cutting force simulation loading device (30), axial cutting force simulation loading device (40), bearing loading unit (50) and torque loading system (60) are installed on the test bench body (10).

[0037] The test bench body (10) is installed on the ground through a vibration damping pad (11). Before carrying out the test, the table top of the test bench body is made level by adjusting the damping pad (11) at the bottom of the test bench body (10). Preferably, several T-slots for fixing are ...

Embodiment 2

[0046] Example 2 A reliability loading test method for the spindle of a CNC lathe

[0047] Adopt the test device of embodiment 1, method is as follows:

[0048] 1) Measure the radial and axial rotation accuracy of the initial state of the tested main shaft (71) with a dial indicator, and measure the static stiffness of the initial state of the tested main shaft;

[0049] 2) The tested spindle (71) is fixed on the test bench body (10) through the spindle box (72), the motor (20) drives the tested spindle to run through the belt (21), and the tested spindle is continuously idling for 72 hours. Stop once every 24 hours to test the rotation accuracy and static stiffness of the tested spindle;

[0050] 3) Carry out a 24h loading test on the tested spindle (71):

[0051] The torque loading system (60) applies torque loading to the measured main shaft through the bearing loading unit (50).

[0052] The radial cutting force simulation loading device (30) applies a radial simulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com