Comprehensive recovery device and method for valuable metal in copper smelting acidic wastewater

A valuable metal recovery device technology, which is applied to the comprehensive recovery device for valuable metals in copper smelting sewage acid, and the field of comprehensive recovery of valuable metals in copper smelting sewage acid, which can solve the problem of valuable metal loss, large fluctuation range, comprehensive recovery and other problems, to achieve the effect of solving the loss of valuable metals, low operating costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

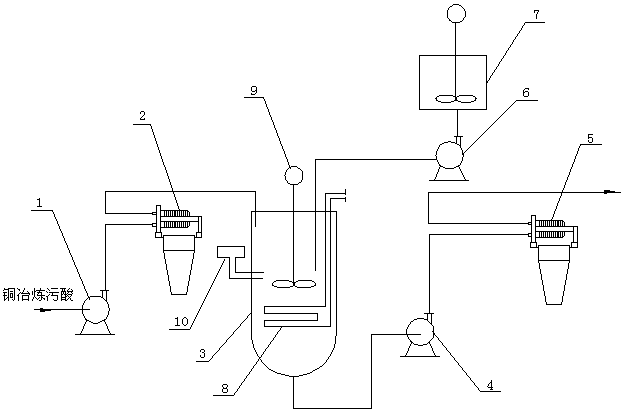

[0028] Such as figure 1 As shown, a copper smelting dirty acid comprehensive recovery device for valuable metals comprises a dirty acid pump 1 connected in sequence, a first filter press 2, a reaction tank 3, a reaction liquid pump 4 and a second filter press 5, and the reaction The top of the tank 3 is connected to the first filter press 2, and the bottom is connected to the reaction liquid pump 4. A steam heating coil 8 and a stirring device 9 are installed in the reaction tank 3. The top of the reaction tank 3 is also connected to a reagent through a metering pump 6. The tank 7 and the reaction tank 3 are also connected with a temperature measuring device 10 .

Embodiment 2

[0030] A method for comprehensively recovering valuable metals from copper smelting sewage acid, using the recovery device described in Example 1. In this embodiment, the copper smelting sewage acid treated contains 80-120 g / l of sulfuric acid, 60-200 g / l of copper, and 60-200 g / l of copper. Arsenic 2-5g / l, lead 2-30mg / l, bismuth 200-500mg / l, rhenium 20-60mg / l, silver 2-20mg / l, including the following steps:

[0031] (1) The copper smelting dirty acid is pumped to the first filter press for pressure filtration to remove solid particles in the dirty acid, and the filtrate enters the reaction tank, and the filter residue is mainly lead sludge, which is transported to the lead smelting system to recover lead ;

[0032] (2) Configure sodium thiosulfate solution with a mass percentage concentration of 10-20% in the reagent tank, add the sodium thiosulfate solution in the reagent tank into the reaction tank through a metering pump, and control the amount of sodium thiosulfate soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com