Method for removing endotoxin in trypsinase

A technology of trypsin and filter cake, which is used in the field of removing endotoxin in trypsin, can solve the problems of long time consumption and inactivation of trypsin, and achieve the effect of improving production efficiency and reducing operation volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

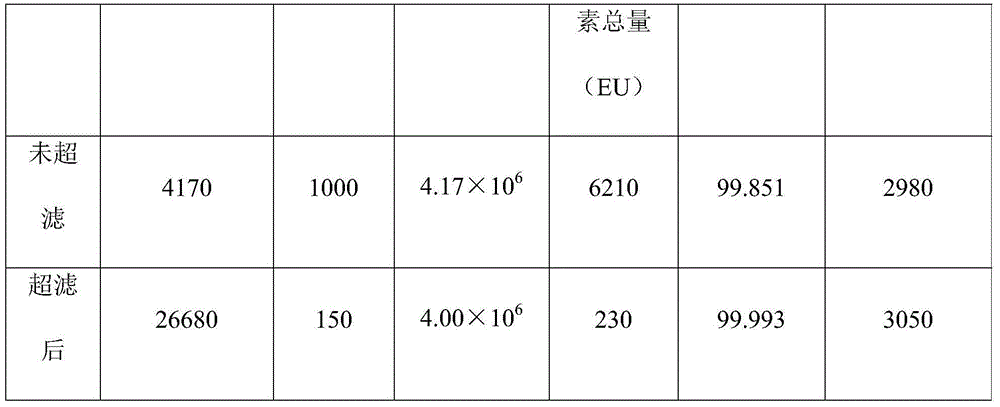

Embodiment 1

[0039]The batch number of trypsin raw material is 120901, which is produced in the processing department of beef and sheep organs in Jining, Inner Mongolia. The trypsin raw material is fresh bovine pancreas soaked in sulfuric acid, minced, salted out and crystallized, and its mass percentage purity should not be lower than 10%. Feed 4000g of protease raw material, stir and dissolve with 5 times the volume (V / W) of purified water first, add 5000mL of 2.5mol / L sulfuric acid solution to adjust the pH to 3.0 to help it dissolve. Measure the volume of the solution, add solid ammonium sulfate into it according to the ratio of 415g / L to make it reach 0.7 saturation, after it dissolves, let it stand for precipitation for 8 hours. Filter the solution with a Buchner funnel and three layers of medium-speed filter paper, weigh the filter cake weight 9115g, add 27345ml of purified water according to three times the weight of the filter cake (V / W), stir and dissolve, add 2.5mol / L sulfuric ac...

Embodiment 2

[0046] Trypsin raw material batch number 120902, produced in Inner Mongolia Jining cattle and sheep organ processing department, trypsin raw material is fresh bovine pancreas soaked in sulfuric acid, minced, salted out and crystallized, its mass percentage purity should not be lower than 10%; Feed 4500g of protease raw material, first stir and dissolve with 5 times the volume (V / W) of purified water, add 2.5mol / L sulfuric acid solution to adjust the pH to 3.0 to help it dissolve. Measure the volume of the solution, add solid ammonium sulfate into it according to the ratio of 415g / L to make it reach 0.7 saturation, after it dissolves, let it stand for precipitation for 8 hours. Filter the solution with a Buchner funnel and three layers of medium-speed filter paper, weigh the filter cake weight 9500g, add 28500ml of purified water according to 3 times the filter cake weight (V / W), stir and dissolve, add 2.5mol / L sulfuric acid solution Adjust the pH to 3.0, add 19000ml of liquid ...

Embodiment 3

[0053] Trypsin raw material batch number 120903, produced in Inner Mongolia Jining cattle and sheep organ processing department, trypsin raw material is fresh bovine pancreas soaked in sulfuric acid, minced, salted out and crystallized, its mass percentage purity should not be lower than 10%; Feed 4500g of protease raw material, first stir and dissolve with 5 times the volume (V / W) of purified water, add 2.5mol / L sulfuric acid solution to adjust the pH to 3.0 to help it dissolve. Measure the volume of the solution, add solid ammonium sulfate into it according to the ratio of 415g / L to make it reach 0.7 saturation, after it dissolves, let it stand for precipitation for 8 hours. Filter the solution with a Buchner funnel and three layers of medium-speed filter paper, weigh the filter cake to 10,000 g, add 30,000 ml of purified water according to three times the weight of the filter cake (V / W), stir and dissolve, then add 2.5 mol / L sulfuric acid solution Adjust the pH to 3.0, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com