Mine water plugging curtain lake slurry preparation process and equipment

A preparation process and water curtain technology, applied in the field of mine curtain grouting, can solve problems such as failure to meet industrial production requirements, slow curtain grouting construction progress, and difficulty in guaranteeing construction quality, and achieve improved preparation efficiency, reasonable equipment configuration, and satisfactory The effect of quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

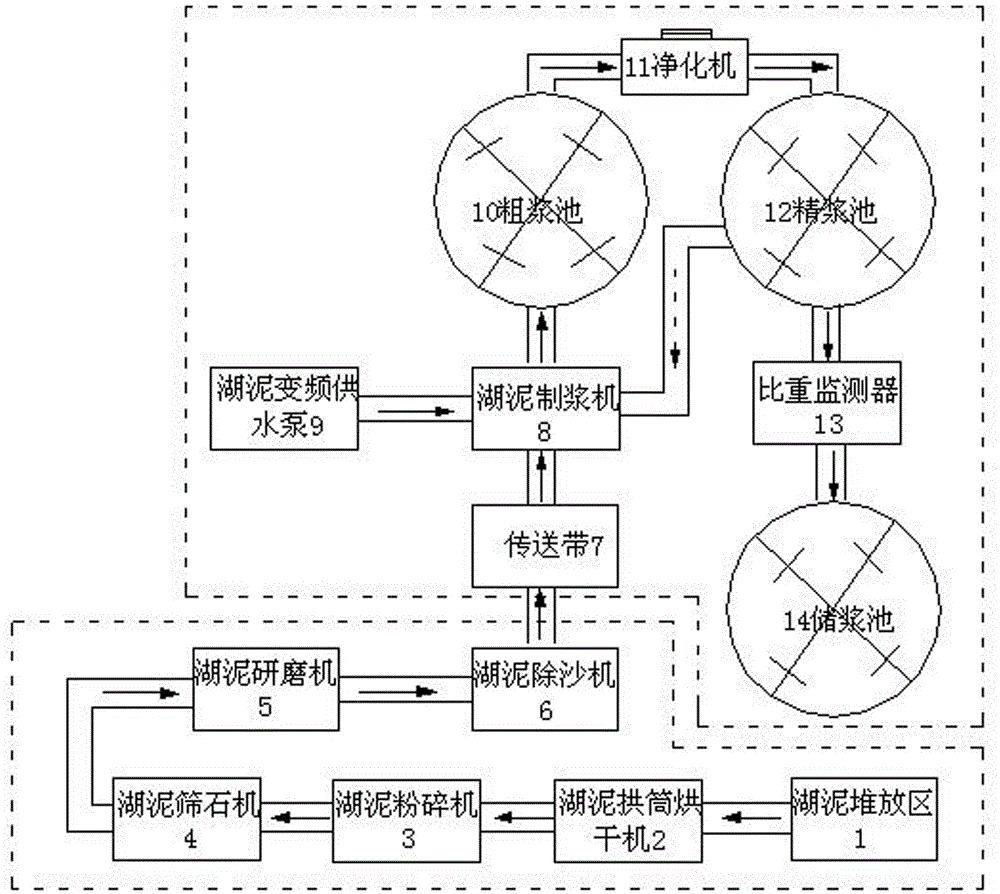

Method used

Image

Examples

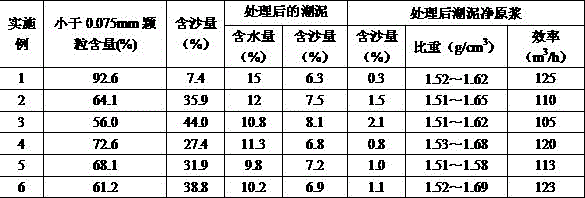

Embodiment 1

[0056] The process is the same as above, and the technical parameters of the lake mud are: the particle content of less than 0.075mm is 92.6%; the sand content is 7.4%; the plastic limit index: the plasticity index is 18.5.

[0057] After the lake mud is processed through the lake mud treatment process, the technical parameters of the treated lake mud are: water content 15%, sand content 6.3%.

[0058] After the preparation process of pure lake mud puree, the technical parameters of the prepared pure lake mud puree are: the sediment content is 0.3%, and the specific gravity is 1.52-1.62g / cm 3 , the lake slurry preparation efficiency is 125m 3 / h. The pass rate is 100%.

Embodiment 2

[0060] The process is the same as above, and the technical parameters of the lake mud are: the particle content of less than 0.075mm is 64.1%; the sand content is 35.9%; the plastic limit index: the plasticity index is 12.2.

[0061] The lake mud is processed through the lake mud treatment process, and the technical parameters of the treated lake mud are: water content 12%, sand content 7.5%.

[0062] After the preparation process of pure lake mud puree, the technical parameters of the prepared pure lake mud puree are: the sediment content is 1.5%, and the specific gravity is 1.51-1.65g / cm 3 , the lake slurry preparation efficiency is 110m 3 / h. The pass rate is 100%.

Embodiment 3

[0064] The process is the same as above, and the technical parameters of the lake mud are: the particle content of less than 0.075mm is 56%; the sand content is 44%; the plastic limit index: the plasticity index is 28.9.

[0065] The lake mud is processed through the lake mud treatment process, and the technical parameters of the treated lake mud are: water content 10.8%, sand content 8.1%.

[0066] After the preparation process of pure lake mud puree, the technical parameters of the prepared pure lake mud puree are: the sediment content is 2.1%, and the specific gravity is 1.51-1.62g / cm 3 , the lake slurry preparation efficiency is 105m 3 / h. The pass rate is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com