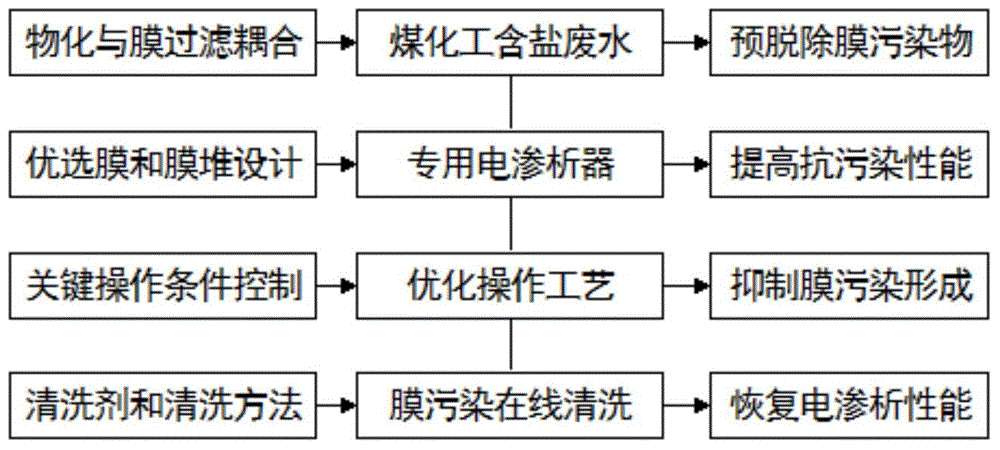

Comprehensive prevention and control method of electrodialysis membrane pollution for desalination of salty wastewater from coal chemical industry

A technology for salty wastewater and electrodialysis membranes, applied in chemical instruments and methods, separation methods, multi-stage water/sewage treatment, etc. , the effect of good membrane pollution control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Coal Chemical Industry Salt Wastewater Electrodialysis Desalination and Membrane Fouling

[0037] Coal chemical industry saline wastewater is desalinated by electrodialysis technology, using constant potential operation, concentrated water and fresh water are filtered with 5 μm PP cotton, and then directly used as water for the electrodialysis system. After 10 batches of continuous desalination experiments, it is found that with electrodialysis Carried out, similar to the simulated wastewater, under the same desalination conditions, the Cl- ion in the fresh water drops to less than 250mg / L to meet the reuse standard. However, in each batch of experiments, the current density showed a downward trend with the desalination process, and the downward trend of different batches was similar. The initial current density of different batches decreased slightly under constant potential. due to membrane fouling. Further dismantling the membrane stack, it was found that ...

Embodiment 2

[0039] Example 2 Membrane Fouling Prevention and Desalination Effect of Electrodialysis of Salt Wastewater in Coal Chemical Industry

[0040] For the water quality of coal chemical industry saline wastewater, the membrane pollution prevention and control methods adopted include: using high-efficiency coagulation, chemical precipitation, catalytic oxidation, multi-media filtration, membrane filtration and other unit technologies and their combinations to pre-remove the coal chemical industry saline wastewater Organic matter, microorganisms, colloids, suspended particles, Ca 2+ and Mg 2+ and other high-valent ions. Among them, COD drops from 100mg / L of raw water to about 20mg / L, and Ca 2+ , Mg 2+ The ion concentration is reduced to below 10mg / L, and the water filtered through the membrane is colorless, clear and transparent.

[0041] The high-efficiency coagulation uses KL-107 as a coagulant. The high-efficiency catalyst KL-CO3 used in the catalytic oxidation, or a composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com