Pneumatic chain bucket feeder

A material machine and chain bucket technology, which is applied in the field of pneumatic chain bucket feeders, can solve problems such as unfavorable health of construction workers, influence on construction progress, and high labor intensity, so as to benefit physical health, improve work efficiency, and reduce The effect of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

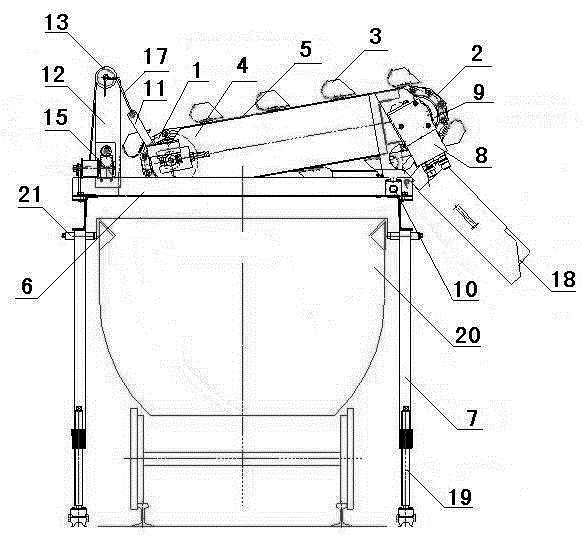

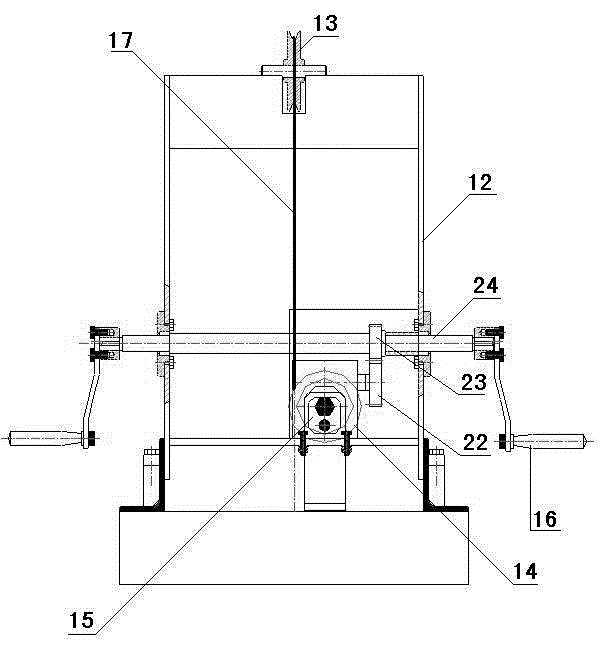

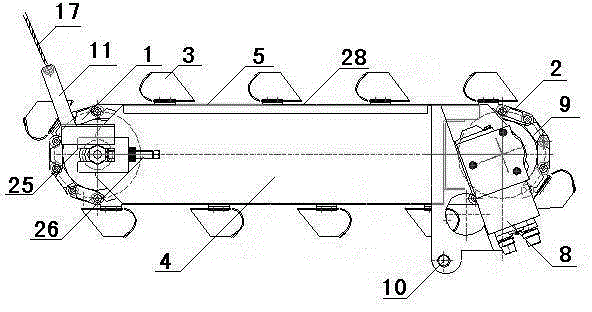

[0010] With reference to the accompanying drawings, a pneumatic chain bucket feeder includes a sprocket chain hopper device 5 composed of a driven sprocket 1, a driving sprocket 9, a chain 2, a hopper 3 and a sprocket mounting bracket 4, and is characterized in that : the device is provided with a strip-shaped rectangular frame 6, one side of the strip-shaped rectangular frame 6 is provided with a swing pin 10, and the whole sprocket chain hopper device 5 swings around the swing pin 10; the position of the swing pin 10 is in the chain The wheel chain hopper device 5 is on one side of the driving sprocket 9, and outside the hopper 3, its axis is parallel to the rotation axis of the sprocket; the sprocket mounting bracket 4 of the sprocket chain hopper device 5 is fixed with an air motor and a reducer Assembly 8; the output shaft 27 of the air motor and reducer assembly 8 is the drive shaft of the drive sprocket 9, and a cross bar bracket 11 is provided on the outer upper side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com