Ball head pressing equipment

A ball head and equipment technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of unfinished press-fitting of the ball head to the operating rod, misjudgment, etc., to ensure that the press-fitting is in place and reduce misjudgment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

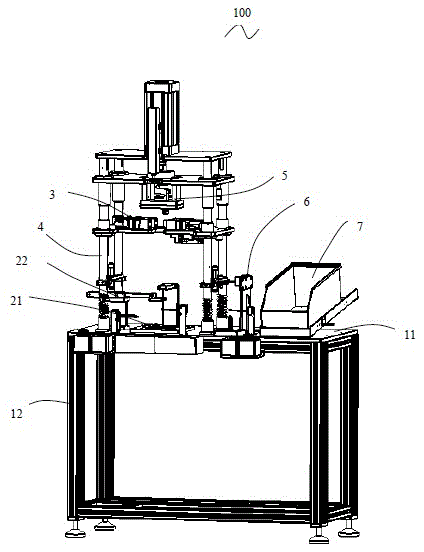

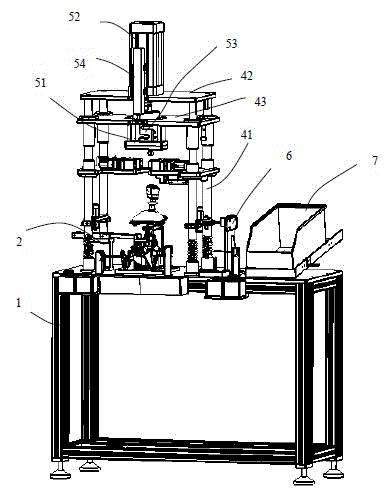

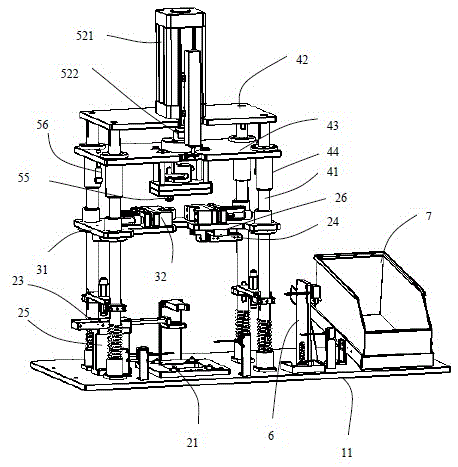

[0021] See Figure 1 to Figure 7 , the ball head press-fitting equipment 100 in an embodiment of the present invention includes a ball head 200 installed on the operating rod 301 of the workpiece 300, including a frame 1, a workpiece fixture 2, a travel frame 4, and a The ball clamp device 3 , the press-fitting device 5 arranged above the ball clamp device 3 , the workpiece detection device 6 for detecting the workpiece 300 , and the magazine device 7 for placing and storing components such as the ball tip 200 . The frame 1 includes a workbench 11 and a frame body 12 for supporting the workbench 11 . The workpiece fixture 2 , travel frame 4 , and workpiece detection device 6 are fixed on the workbench 11 . The pressing device 5 is arranged on the travel frame 4 and can move up and down along the travel frame 4 .

[0022] The workpiece fixture 2 includes a chassis clamp 21 for fixing a chassis 302 of the workpiece 300 and an operating rod clamp 22 for fixing an operating rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com