A special coating sand for engine cylinder water jacket and preparation method thereof

A technology of engine cylinder block and coated sand, which is applied in the field of coated sand, can solve the problems that the performance of coated sand is not shown, the coated sand is prone to veins, and the preparation method is too large, so as to improve the quality of internal and external surfaces, Effects of reducing vein defects and ease of production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

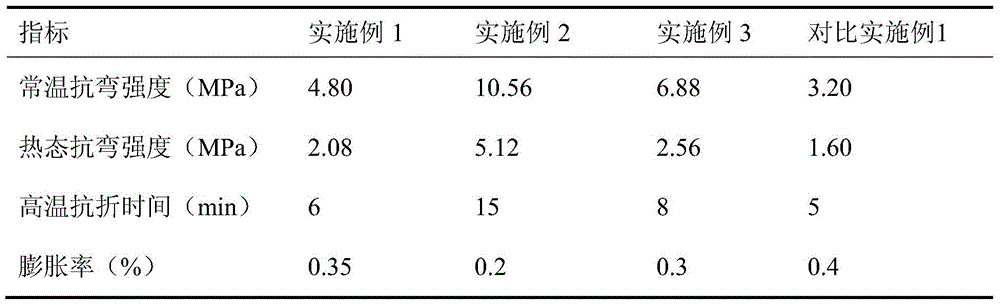

Examples

Embodiment 1

[0040] The coated sand specially used for the water jacket of the engine block of the present embodiment includes raw sand, binder, curing agent, coupling agent, lubricant and refractory particles, wherein the binder accounts for 1% of the weight of the original sand, and the curing agent accounts for 1% of the weight of the viscose. 12% of the weight of the binder, the coupling agent accounts for 0.1% of the weight of the binder, the lubricant accounts for 1% of the weight of the binder, and the refractory particles account for 0.2% of the weight of the original sand.

[0041] The binder in this embodiment is specifically thermoplastic phenolic resin, the curing agent is hexamethylenetetramine, the coupling agent is γ-aminopropyltriethoxysilane, and the lubricant is calcium stearate.

[0042] The refractory particle composition and its weight ratio in this embodiment are: 10 parts of refractory particle A and 90 parts of refractory particle B, wherein refractory particle A inc...

Embodiment 2

[0046] The coated sand specially used for the engine block water jacket of this embodiment includes raw sand, binder, curing agent, coupling agent, lubricant and refractory particles, wherein the binder accounts for 4.0% of the weight of the original sand, and the curing agent accounts for 4.0% of the weight of the viscose. 20% of the weight of the binder, the coupling agent accounts for 0.5% of the weight of the binder, the lubricant accounts for 5% of the weight of the binder, and the refractory particles account for 2.0% of the weight of the original sand.

[0047] The binder in this embodiment is specifically thermoplastic phenolic resin, the curing agent is hexamethylenetetramine, the coupling agent is γ-aminopropyltriethoxysilane, and the lubricant is calcium stearate.

[0048] The refractory particle composition and its weight ratio in this embodiment are: 20 parts of refractory particle A and 80 parts of refractory particle B, wherein refractory particle A includes 70 p...

Embodiment 3

[0052]The special coated sand for engine block water jacket of this embodiment includes raw sand, binder, curing agent, coupling agent, lubricant and refractory particles, wherein the binder accounts for 1.5% of the weight of the original sand, and the curing agent accounts for 1.5% of the weight of the viscose. 14% of the weight of the binder, the coupling agent accounts for 0.3% of the weight of the binder, the lubricant accounts for 3% of the weight of the binder, and the refractory particles account for 1.5% of the weight of the original sand.

[0053] The binder in this embodiment is specifically thermoplastic phenolic resin, the curing agent is hexamethylenetetramine, the coupling agent is γ-aminopropyltriethoxysilane, and the lubricant is calcium stearate.

[0054] The refractory particle composition and its weight ratio in this embodiment are: 30 parts of refractory particle A and 70 parts of refractory particle B, wherein refractory particle A includes 40 parts of kaol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com