A solar tube cleaning device

A cleaning device and solar technology, applied in the directions of solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve the problems of low cleaning efficiency, waste of labor and high cost, and achieve good cleaning effect and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

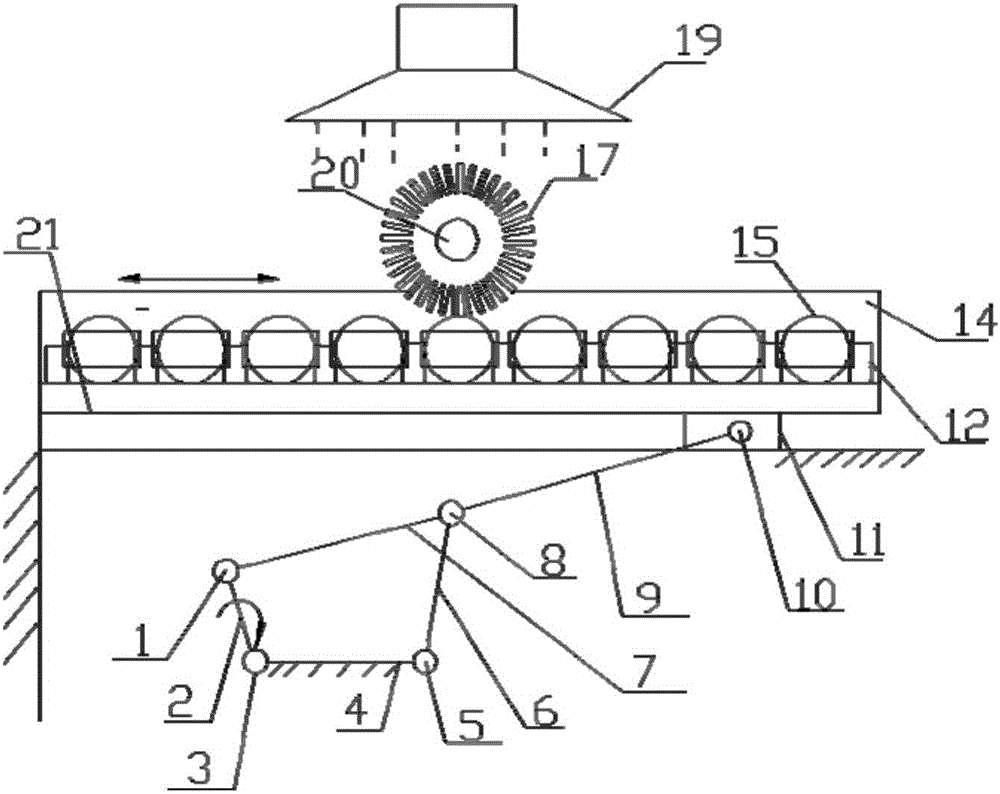

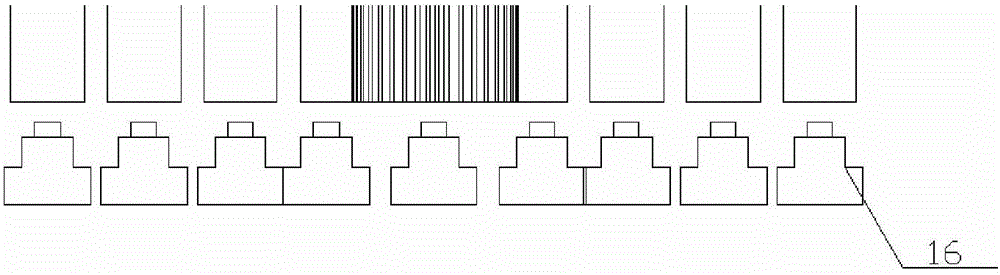

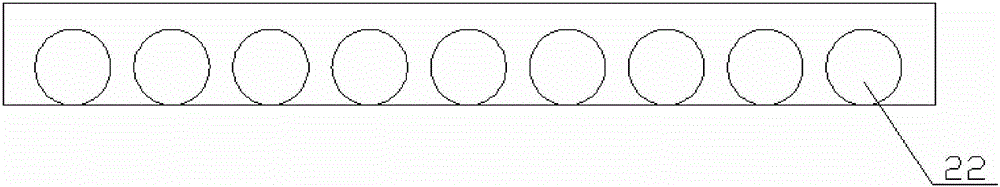

[0011] A solar tube cleaning device is composed of hinge 11, crank 12, hinge 23, frame 4, hinge 35, crank 26, connecting rod 17, hinge 48, connecting rod 29, hinge 510, slider 11, foam splint 12, Foam baffle 14, solar tube 15, high-pressure water gun 16, cylindrical brush 17, sprinkler 19, drive wheel 20, loading platform 21 form. , is characterized in that: hinge 11, hinge 23, hinge 35, hinge 48, hinge 510, and crank 12, crank 26, connecting rod 17, connecting rod 29, slider 11 jointly assemble double crank slider four-bar mechanism, slide Block 11 is connected with loading board 21, drives loading board 21 to do reciprocating motion, and foam splint 12, foam baffle plate 14 are all installed on loading board 21, and cylindrical hairbrush 17 is installed on the driving wheel 20, and when carrying Move back and forth on the pallet 21, the sprinkler 19 is installed on the top of the cylindrical hair brush 17, the high-pressure water gun 16 is fixed on the cargo board 21, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com