Based on foldable warp knitting machine fixing bracket for easy transportation

A fixed bracket and foldable technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of occupying a large space, lack of practicability, and inconvenient height adjustment and movement of the fixed bracket, so as to save space, The effect of convenient subsequent transportation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

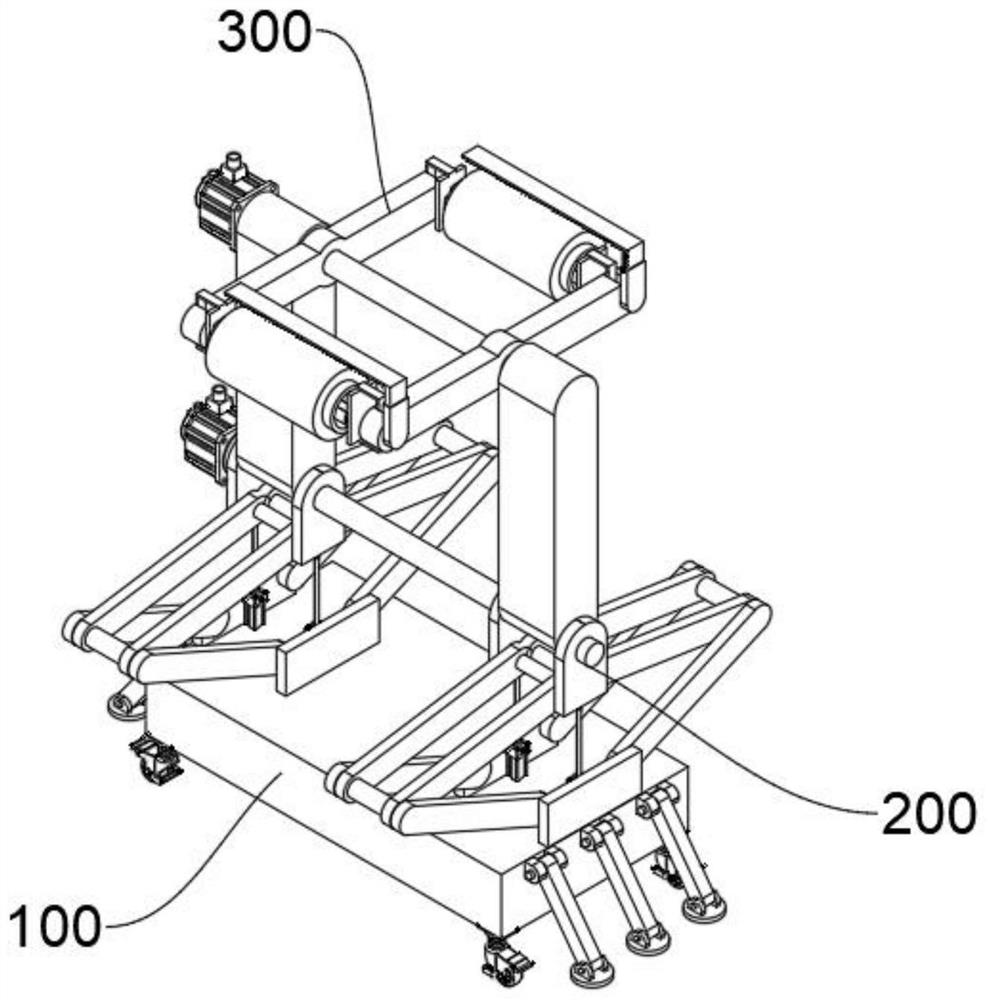

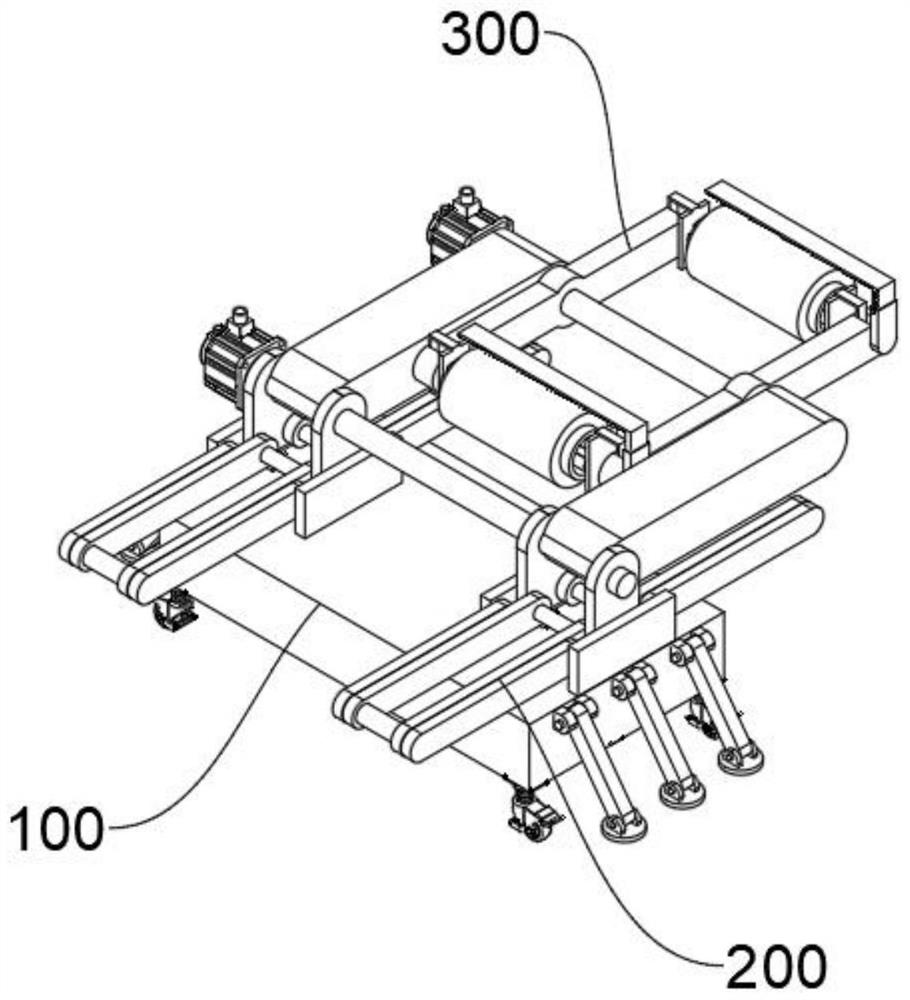

[0048] see Figure 1-Figure 15 As shown, the present embodiment provides a warp knitting machine fixing bracket based on a foldable type for easy transportation, which at least includes:

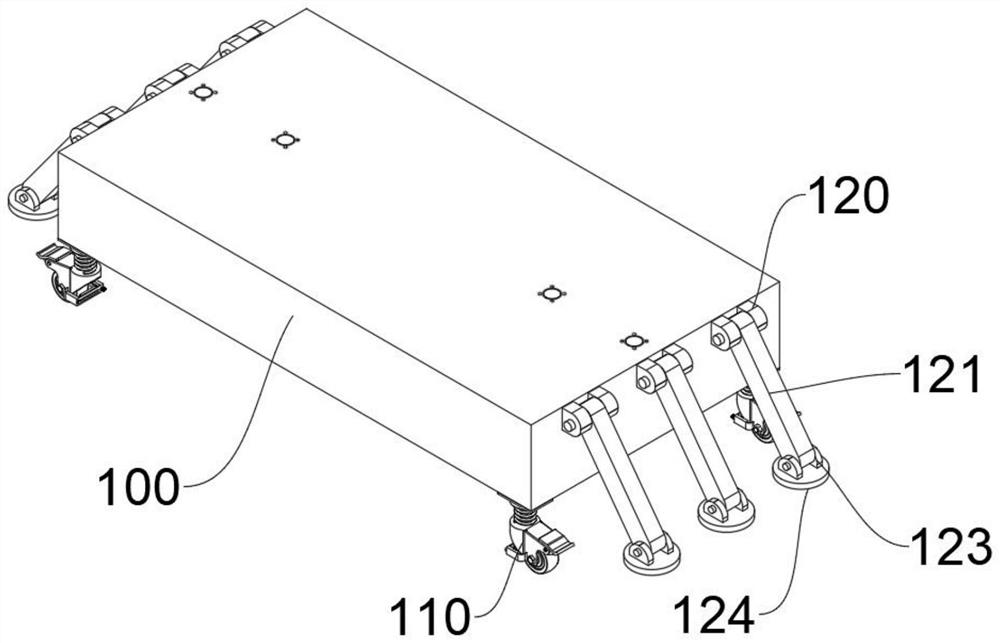

[0049] The bottom plate 100 and the bottom of the bottom plate 100 are provided with universal wheels 110 near the corners. The top of the universal wheels 110 is provided with a buffer spring 111, and the top of the buffer spring 111 is fixedly connected with a mounting plate 112. By setting the buffer spring 111, the When the vibration is bumpy, the buffer spring 111 is compressed, and under the action of the elastic force of the buffer spring 111, the damage to the base plate 100 caused by the rigid impact of the vibration can be buffered, which is beneficial to prolong the service life. The top of the mounting plate 112 is fixed on the bottom of the base plate 100 by bolt threads. By pushing and pulling the bottom plate 100, the universal wheel 110 is rotated, so that the universal wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com