Realize the processing technology of bright fog on the surface of plastic shell

A technology of plastic shell and processing technology, which is applied to the device for coating liquid on the surface, special surface, coating, etc. It can solve the problems of not being able to realize the same body of bright fog, complicated manufacturing process, and unfavorable heat dissipation of the product, and achieve good gloss. , simple processing technology and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

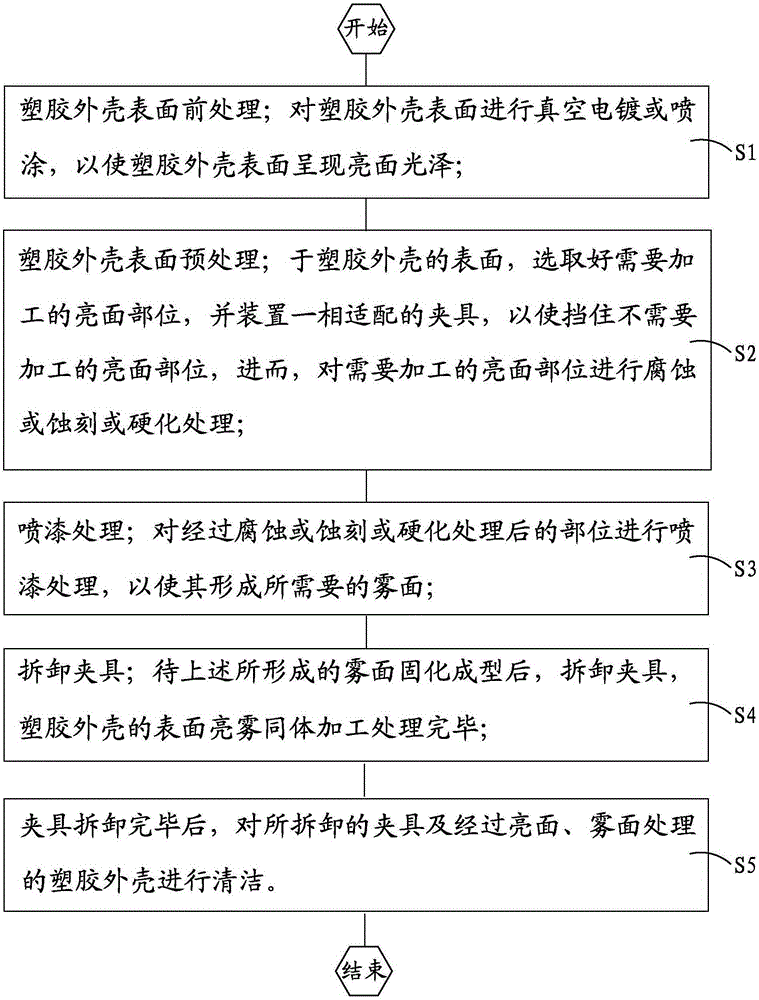

[0060] This embodiment provides a process for processing a bright surface and a matte surface on the surface of the middle frame of a plastic mobile phone case;

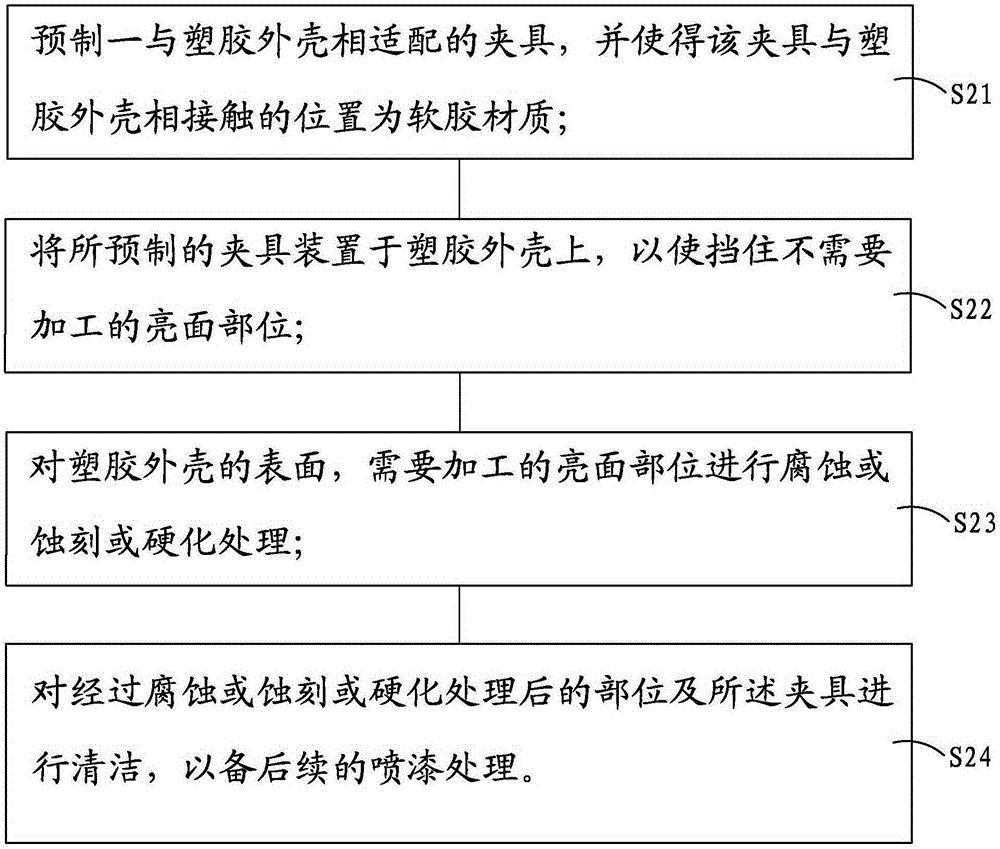

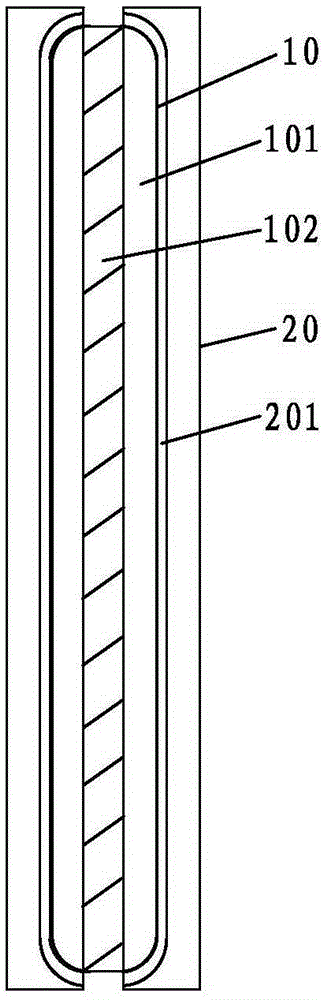

[0061] Control figure 1 and figure 2 And refer to image 3 , Figure 4 and Figure 5 Shown image 3 The middle part of is a schematic cross-sectional view of the longitudinal structure of the middle frame 10 of a mobile phone case, and matching clamps 20 are fixed on both sides. The solution of this embodiment is to perform matte treatment on the middle part of the surface of the middle frame 10 of the mobile phone case.

[0062] In the specific implementation of this embodiment, first, the surface of the middle frame 10 of the mobile phone case is pre-treated, that is, the surface of the middle frame 10 of the mobile phone case is vacuum electroplated or sprayed to make the surface of the middle frame 10 of the mobile phone case appear bright and glossy. ;

[0063] Furthermore, a clamp 20 adapted to the middle frame 10 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com