Raspberry stubble flattening and crushing integrated machine with special-shaped conveying rollers

An all-in-one machine and stubble-leveling technology, which is applied to plant waste crushing, mechanical equipment, agricultural machinery and tools, etc., can solve the problems of poor operation effect, low operation efficiency, easy hand injury, etc., to protect the planting environment and achieve good crushing effect , High stubble efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] In order to help understand the above-mentioned basic mode of the present invention, describe with reference to accompanying drawing:

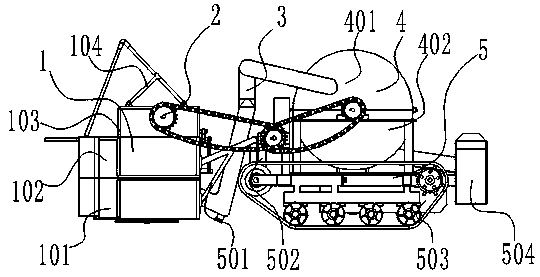

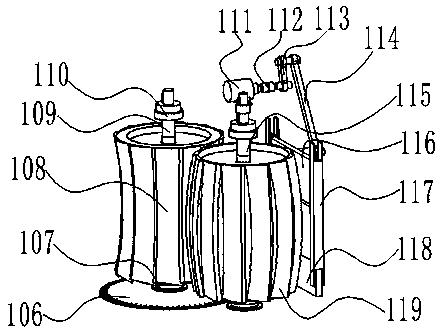

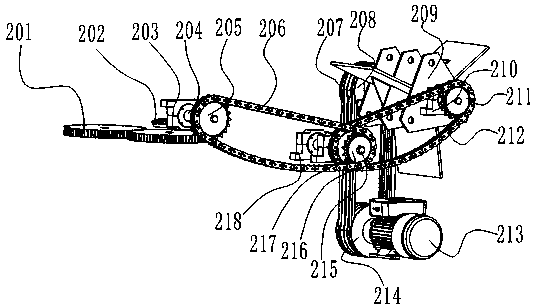

[0023] The all-in-one machine for raspberry stubble crushing includes: stubble flat device 1, transmission system 2, air duct device 3, crushing device 4, and chassis 5; 102, upper shell 103, push rod 104, circular saw disc 106, bearing end cover 107, left counter roller 108, left shaft 109, bearing 110, motor I111, coupling 112, crank 113, connecting rod 114, right shaft 115, moving knife 116, slideway 117, fixed knife 118, right pair of rollers 119, left shaft 109 and right shaft 115 are connected with lower shell chassis 101, lower shell upper plate 102 through bearing 110 and bearing end cover 107, upper The lower end of the shell 103 is connected with the upper plate 102 of the lower shell, and the upper end is connected with the push rod 104; the circular saw disc 106 is connected with the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com