Full-automatic cruising batch feeding ship for prawn pond

A fully automatic feeding boat technology, which is applied to special-purpose ships, applications, motor vehicles, etc., can solve the problems of changing feeding locations, affecting feeding effects, uneven bulk materials, etc., to achieve energy saving, good feeding effect, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

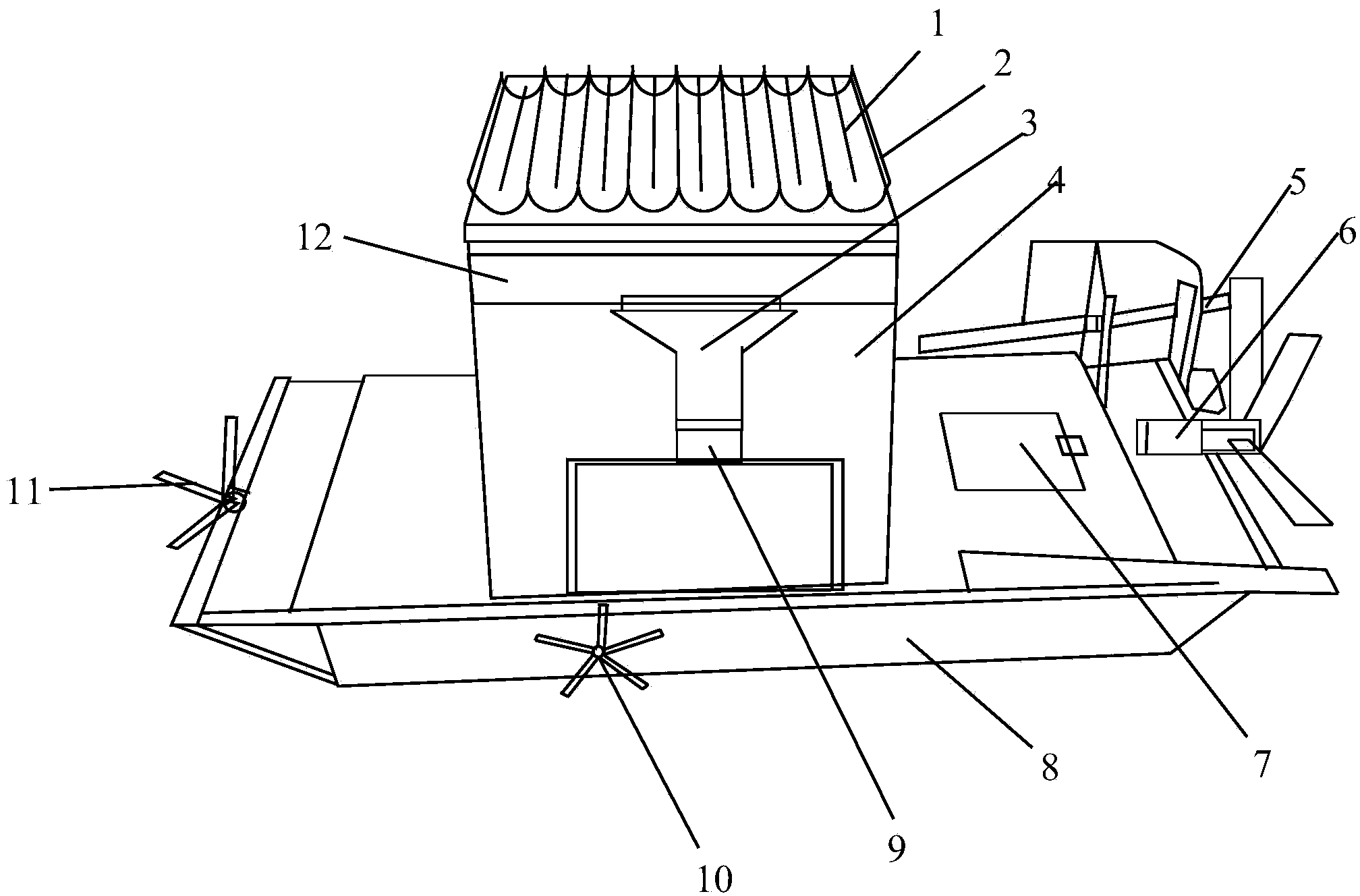

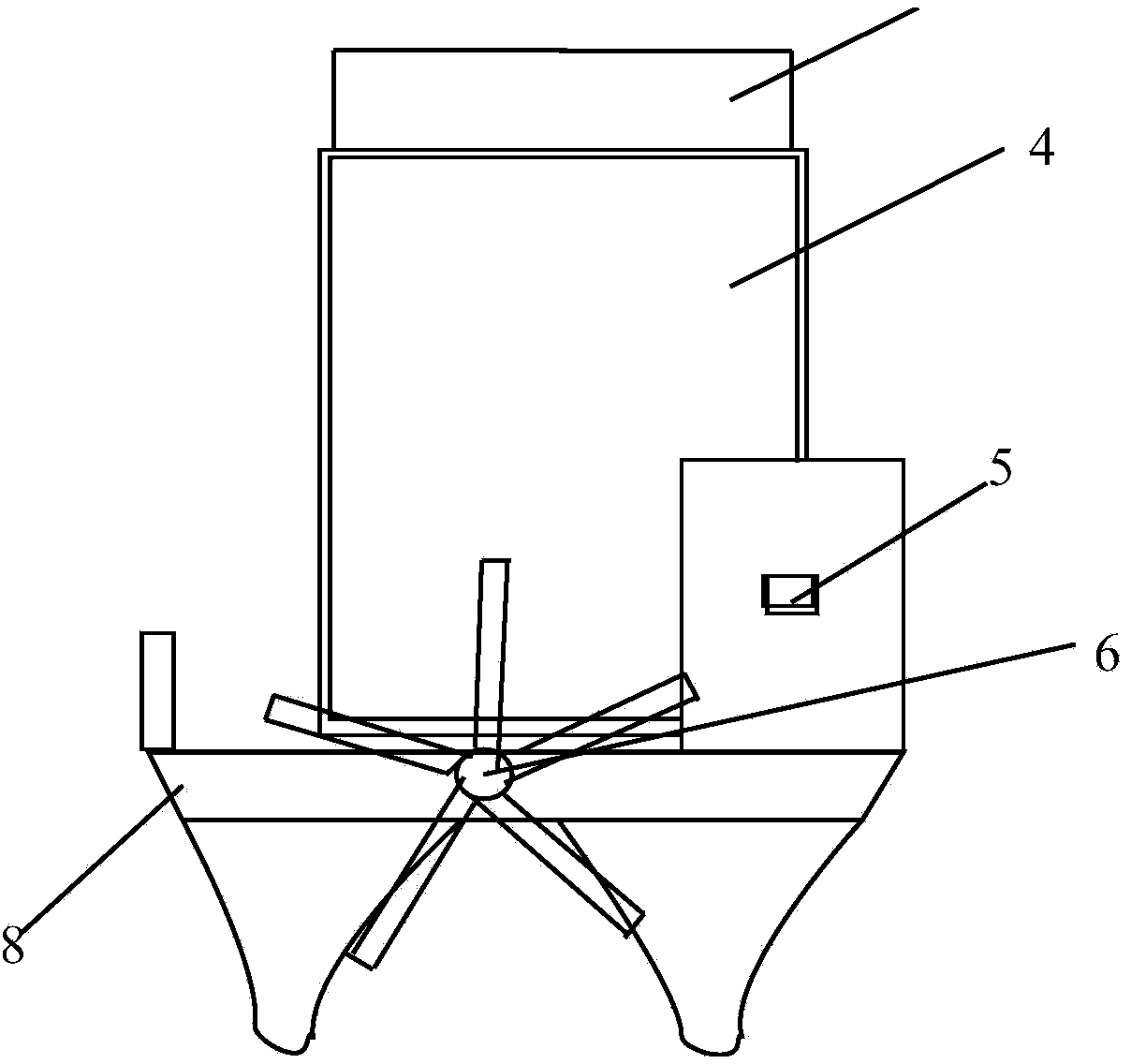

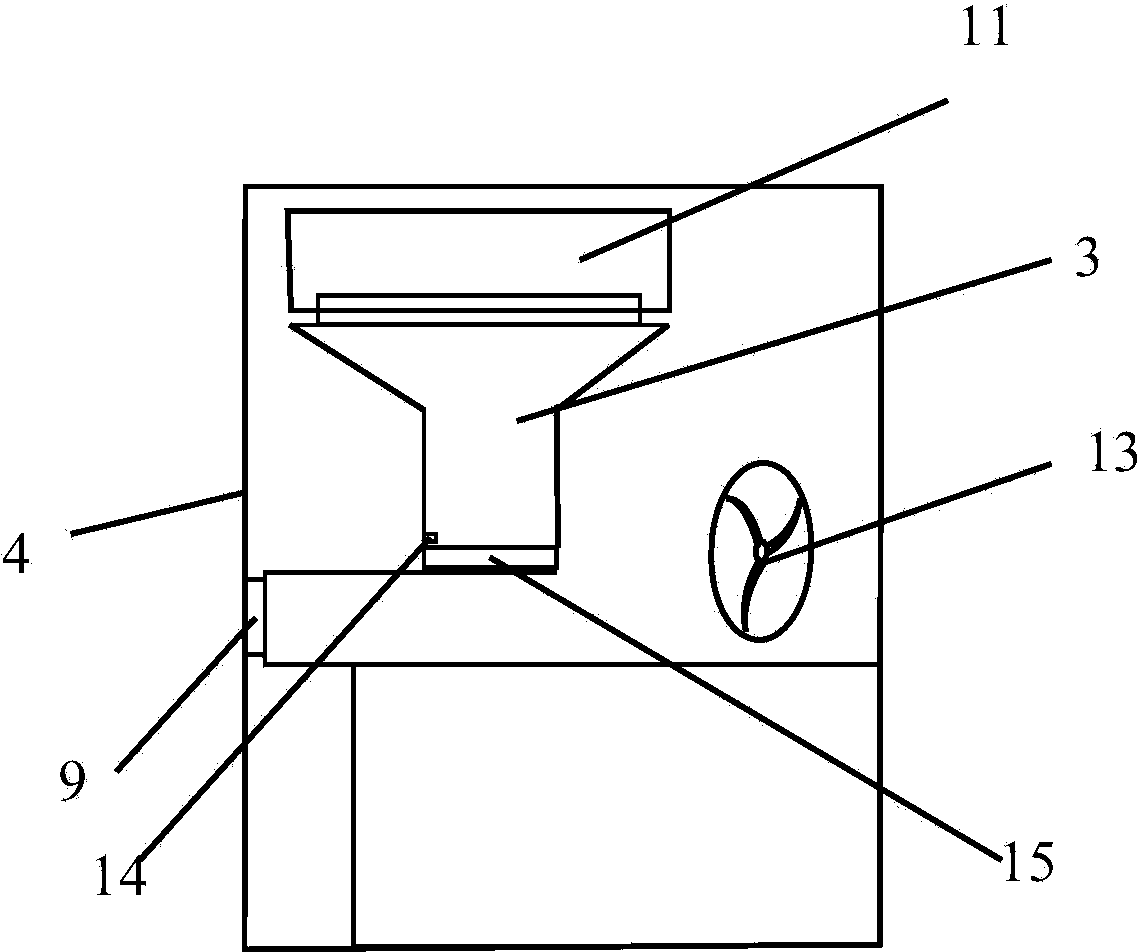

[0017] Such as figure 1 , 2 As shown, the present invention provides a kind of full-automatic cruising feeding boat for prawn ponds, including hull 8, feeding box 4, feeding controller 6, distance detector 5 and solar panel 1, feeding box 4, distance detector 5 They are all installed on the hull 8. The hull 8 is a two-body structure as a whole. It is injection molded by engineering plastic molds. It is made of corrosion-resistant materials, with tough lines and good corrosion resistance, stability and wind and wave resistance. There are main propellers 11, and auxiliary propellers 10 are respectively arranged on the both sides of the hull 8, which greatly reduces the movement resistance of the hull; the main propeller 11 and the auxiliary propellers 10 are equipped with reticulated protective covers to prevent aquatic plants from being entangled; There is a GPS locator, which can effectively prevent the yaw of the ship during driving. The GPS locator is connected with the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com