Secondary battery assembly

A technology for secondary batteries and components, applied in the direction of secondary batteries, battery pack components, secondary battery manufacturing, etc. The effect of uniform surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the best mode embodying the present invention will be described in detail with reference to the drawings. In this embodiment, the present invention is applied to a battery pack in which a plurality of lithium ion secondary batteries are stacked and connected to each other.

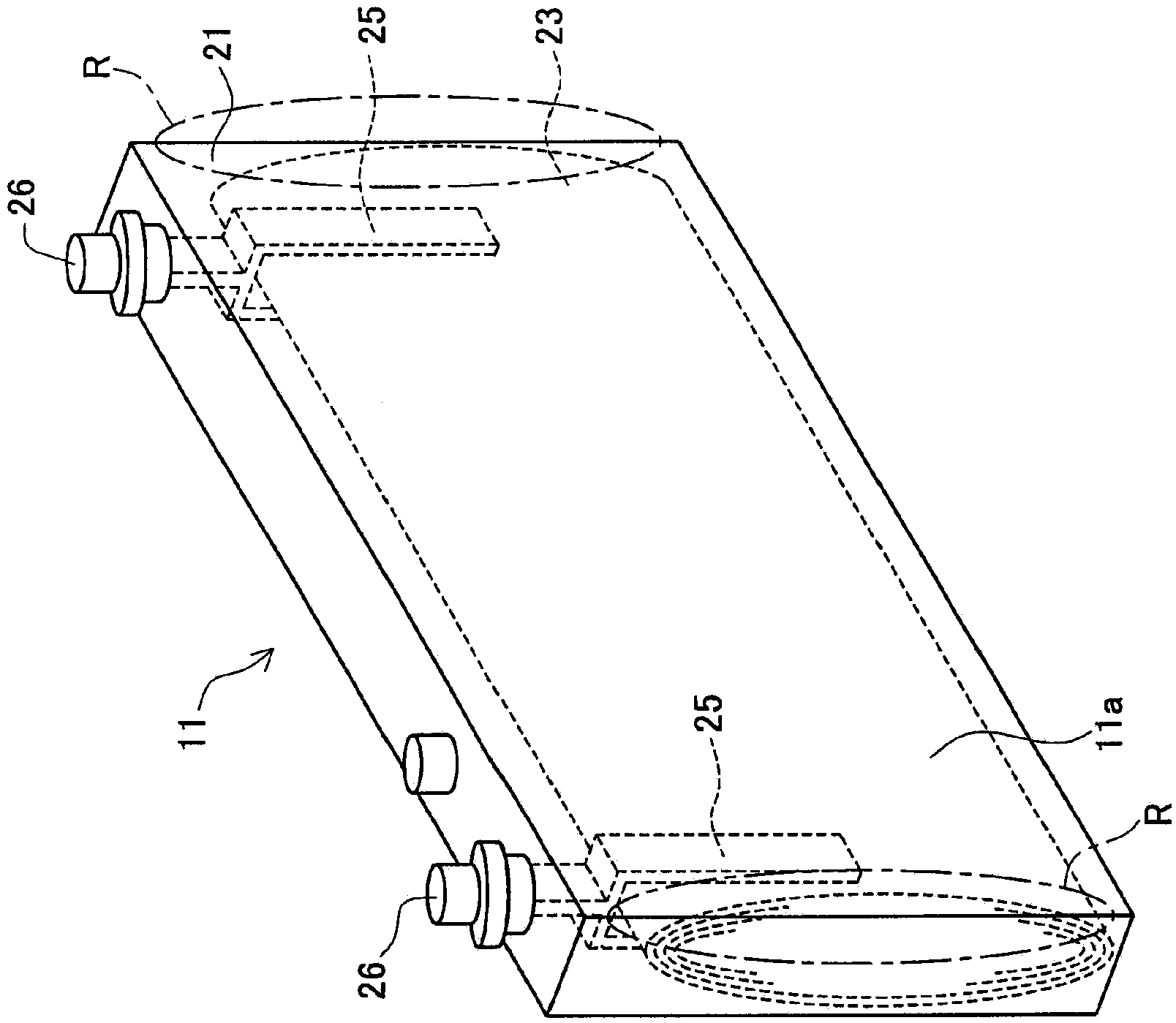

[0036] Such as figure 1 As shown, the battery pack 1 of this embodiment has a plurality of single cells 11 , a plurality of contact members 12 , and two restraint members 13 . Cells 11 and contact members 12 are stacked alternately, and constraining members 13 are arranged on both sides of the whole. Both ends of the restraining band 14 are respectively fixed to the restraining members 13 on both sides, whereby the restraining members 13 are mutually restrained. Thus, the restraint member 13 presses the plurality of cells 11 and the like located therebetween from both sides. In this embodiment, the battery pack 1 corresponds to a secondary battery pack.

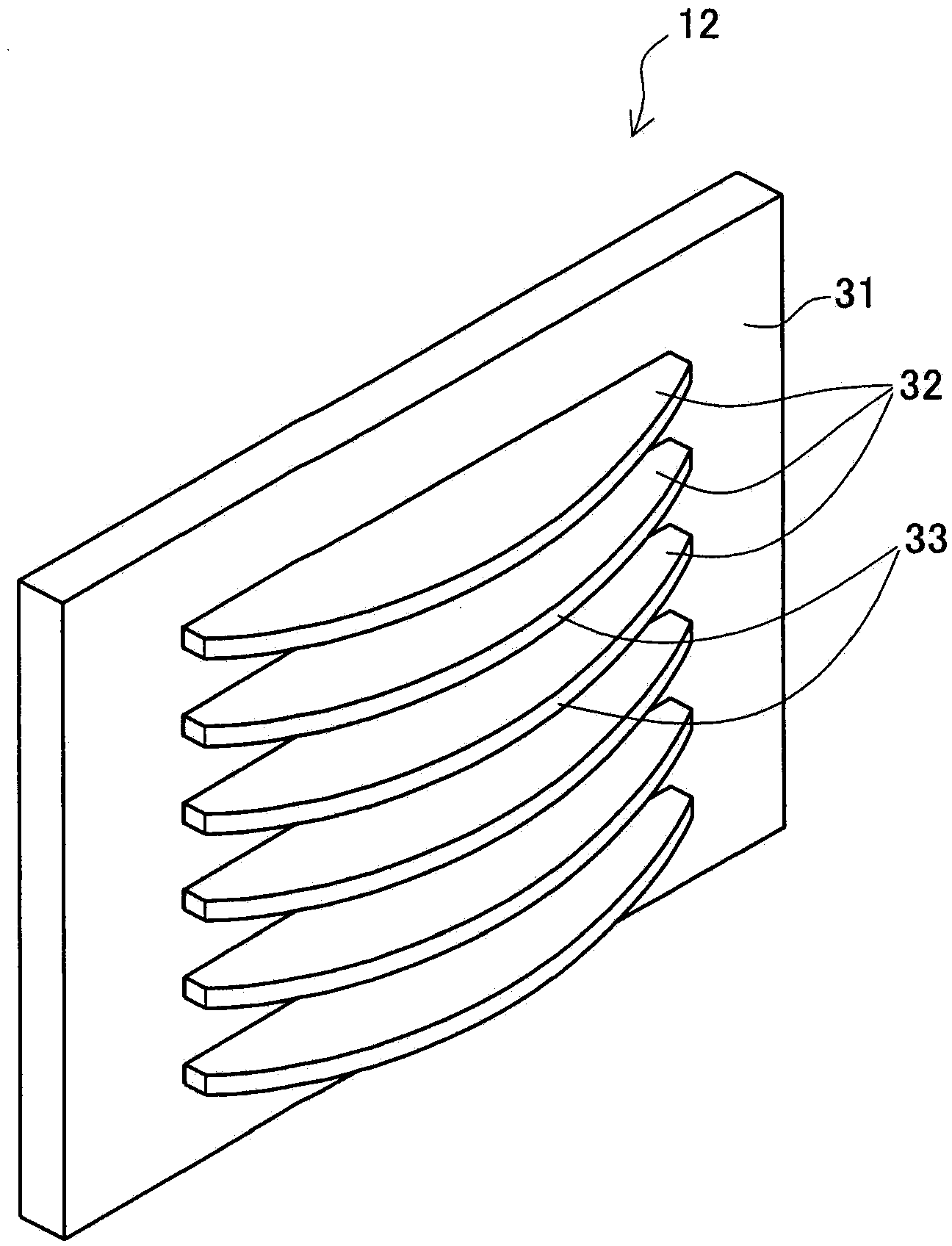

[0037] Such as figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com