Stable powder phytic acid composition and manufacture method thereof

A technology of powder and composition, applied in the field of powder phytic acid composition, can solve problems such as inability to be eaten, and achieve the effects of improving taste, improving quality and promoting the effect of flavor improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

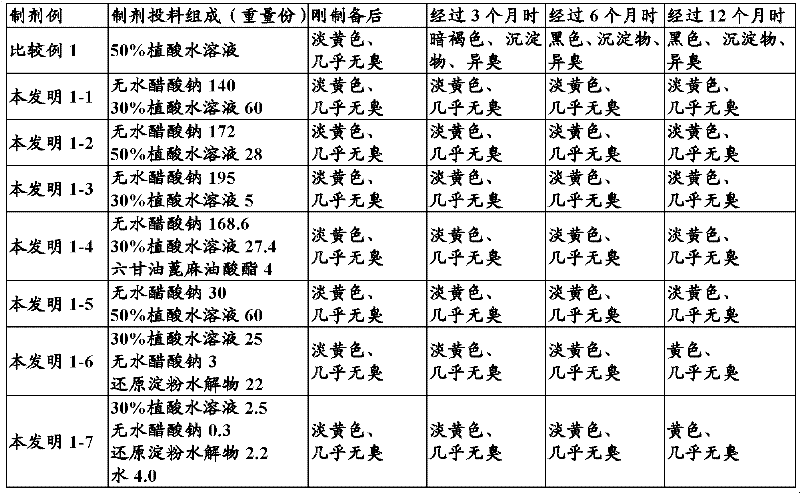

[0066] Next, the preparation method of the preparation example is demonstrated concretely.

[0067] 【Powder preparation (1-1)】

[0068] Put 140 g of anhydrous sodium acetate powder in a mixer with a diameter of 20 cm and two rotating stirring blades up and down, and add a small amount of 30% phytic acid aqueous solution for about 15 minutes while stirring to make uniform adsorption. The mixture is formed at 40-60°C through the exothermic reaction of adsorption, and the temperature gradually decreases during the continuation of stirring. After cooling, the mixture was lightly pulverized and sieved through a 2×2 mm sieve to obtain a powder formulation (1-1).

[0069] 【Powder preparation (1-2)】

[0070] By the same operation as above-mentioned (1-1), 172g of anhydrous sodium acetate powder is stirred in a blender with a small amount of 50% phytic acid aqueous solution 28g, stirred, adsorbed, cooled, pulverized, and sieved to obtain a powder preparation (1 -2).

[0071] 【Powde...

Embodiment 2

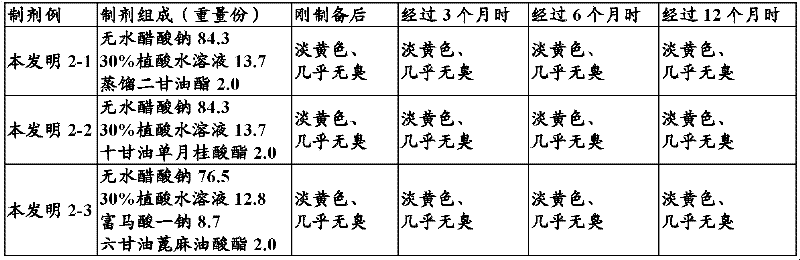

[0086] The following powder formulations were prepared in the same manner as the respective formulations of Example 1, and changes over time at room temperature were observed. The results are shown in the table below.

[0087] 【Table 2】

[0088]

[0089] As shown in Table 2, the formulations described in formulation examples (2-1) to (2-3) showed almost no change in color and odor over time, and long-term stability as a powder formulation was confirmed. In addition, the 1% aqueous solution of their powder is almost colorless and odorless.

Embodiment 3

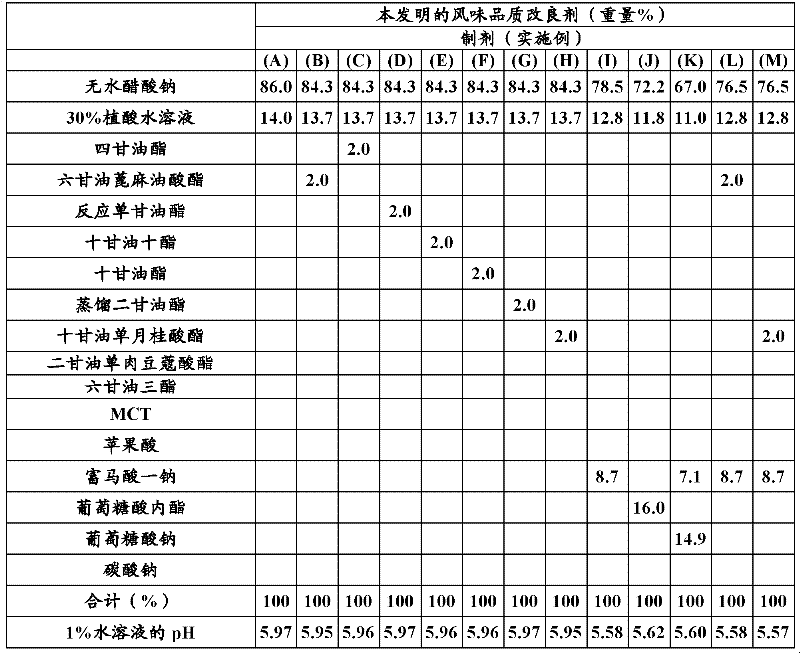

[0091] Based on the method of Example 1, formulations (A) to (Z) were prepared using the components described in Table 3-1 and Table 3-2.

[0092] 【Table 3-1】

[0093]

[0094] 【Table 3-2】

[0095]

[0096] In addition, each emulsifier used in Table 3-1 and Table 3-2 is as follows.

[0097] Hexaglycerol ricinoleate (manufactured by Riken Vitamin Co., Ltd.; trade name: Poem PR-300)

[0098] Tetraglycerol fatty acid ester (manufactured by Sakamoto Pharmaceutical Co., Ltd.; trade name: SYGrista-CR-310)

[0099] Glycerin monofatty acid ester (manufactured by Riken Vitamin Co., Ltd.; brand name: Poem P-200)

[0100] Decaclycerol deca fatty acid ester (manufactured by Sakamoto Pharmaceutical Co., Ltd.; trade name: SY Grista-DA0-7S)

[0101] Decaclycerol fatty acid ester (manufactured by Sakamoto Pharmaceutical Co., Ltd.; trade name: SY Glista-OE-750)

[0102] Distilled diglycerin fatty acid ester (manufactured by Riken Vitamin Co., Ltd.; trade name: Poem DS-100A)

[0103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com