Heat-aging-resistant shading polypropylene material and preparation method thereof

A polypropylene material, heat-resistant aging technology, applied in the field of materials, can solve the problems of anti-oxidation performance of deteriorated materials, high risk of fire, failure of flame retardancy, etc., to achieve the effect of inhibiting deterioration, ensuring flame retardancy, and stable properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An embodiment of the heat-aging-resistant light-shielding polypropylene material of the present invention, the preparation method of the heat-aging-resistant light-shielding polypropylene material comprises the following steps:

[0038] Put each component into a high-speed mixer with a speed of 1000rpm and a temperature of 40-60°C and mix evenly for 8 minutes, then transfer to a twin-screw extruder and extrude at a temperature of 190-220°C. After cooling and granulating, the obtained A light-shielding polypropylene material resistant to heat aging is described.

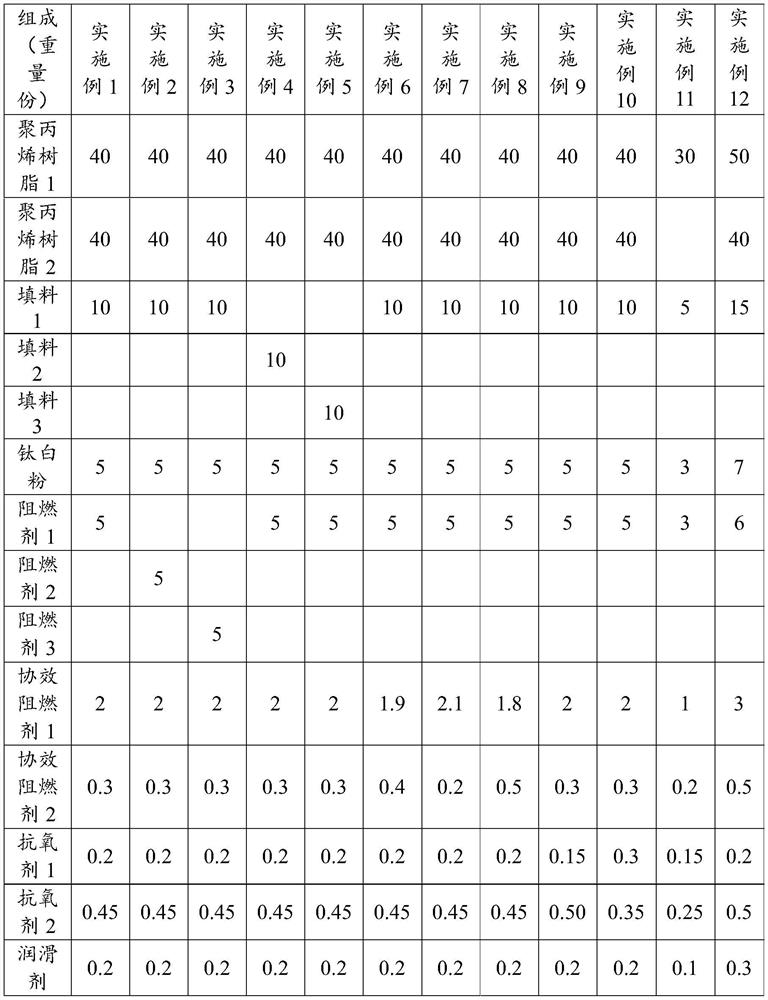

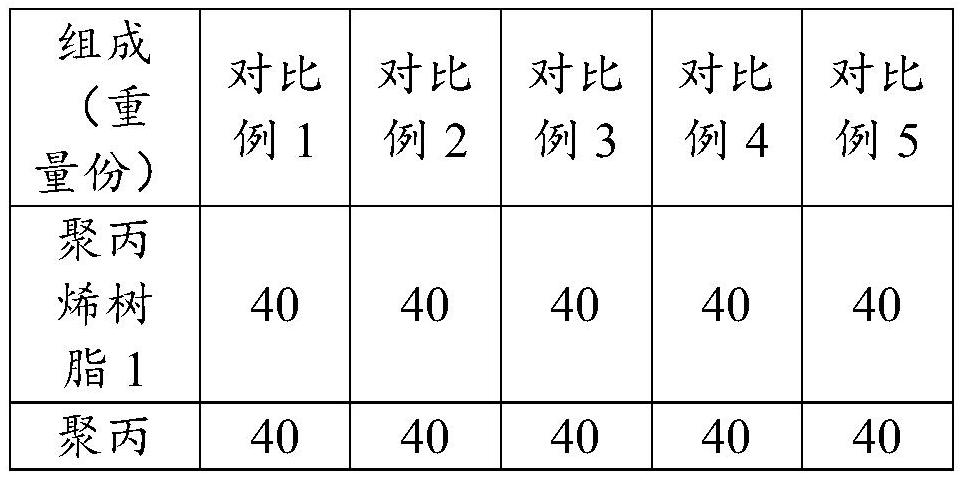

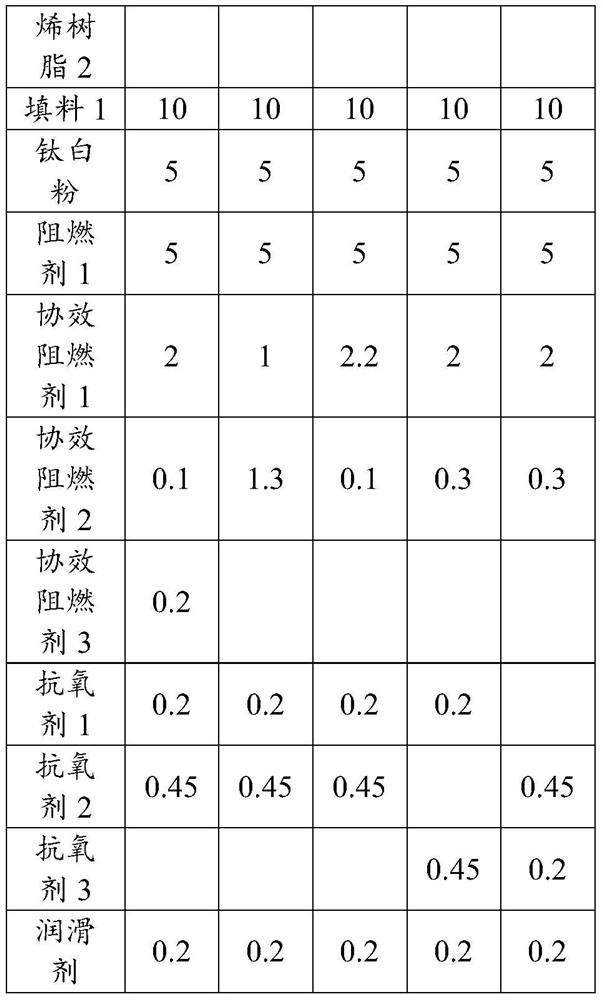

Embodiment 2~12

[0040] The difference between the heat-aging-resistant light-shielding polypropylene material described in Examples 2-12 and the heat-aging-resistant light-shielding polypropylene material described in Example 1 lies in the composition or proportion of the raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt mass flow rate | aaaaa | aaaaa |

| Melt mass flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com