An improved solar dryer with enhanced efficiency of drying

A drying efficiency, solar collector technology, applied in the field of improved solar dryers, which can solve the problems not mentioned, not suitable for drying all food products, low temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

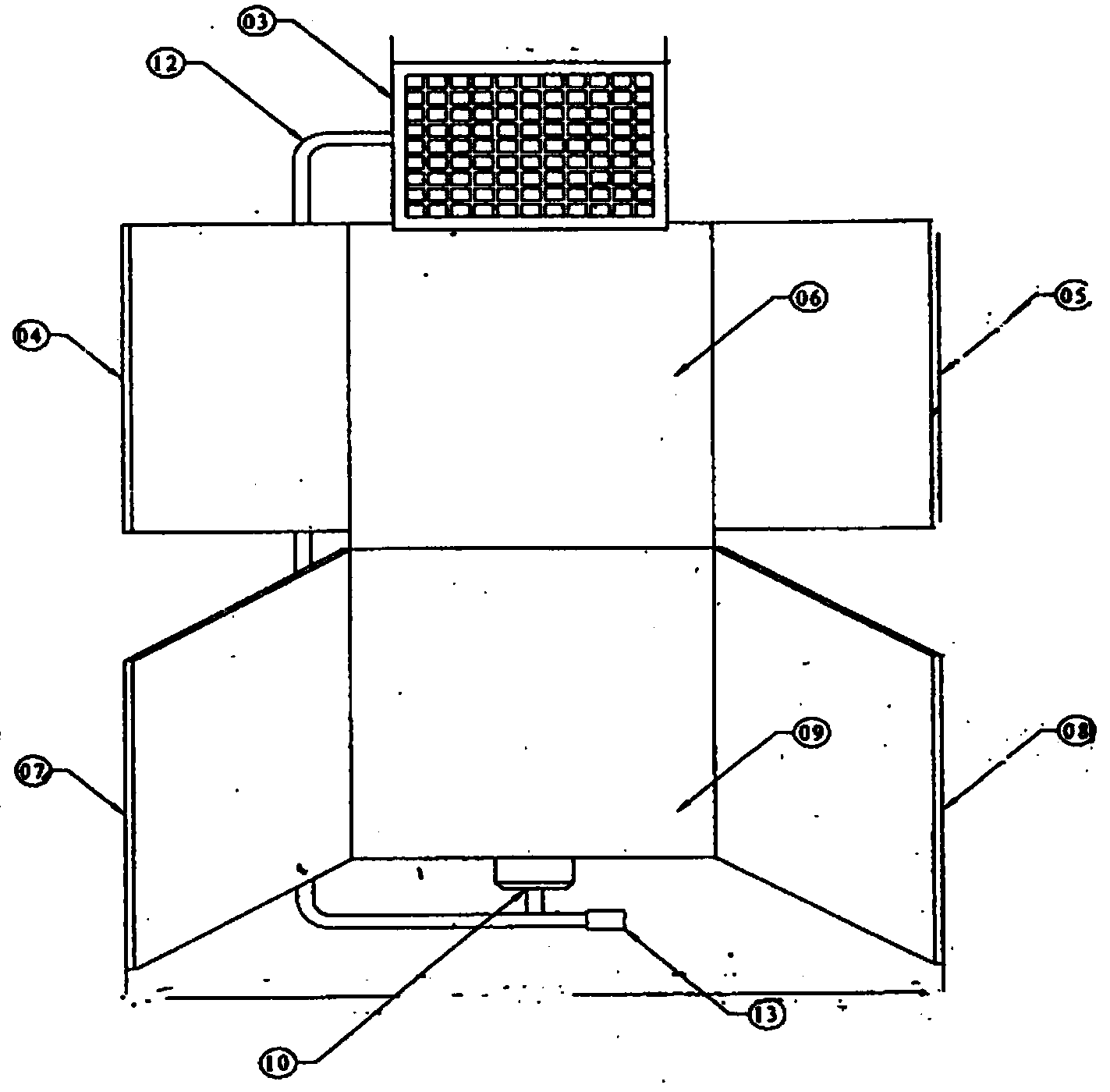

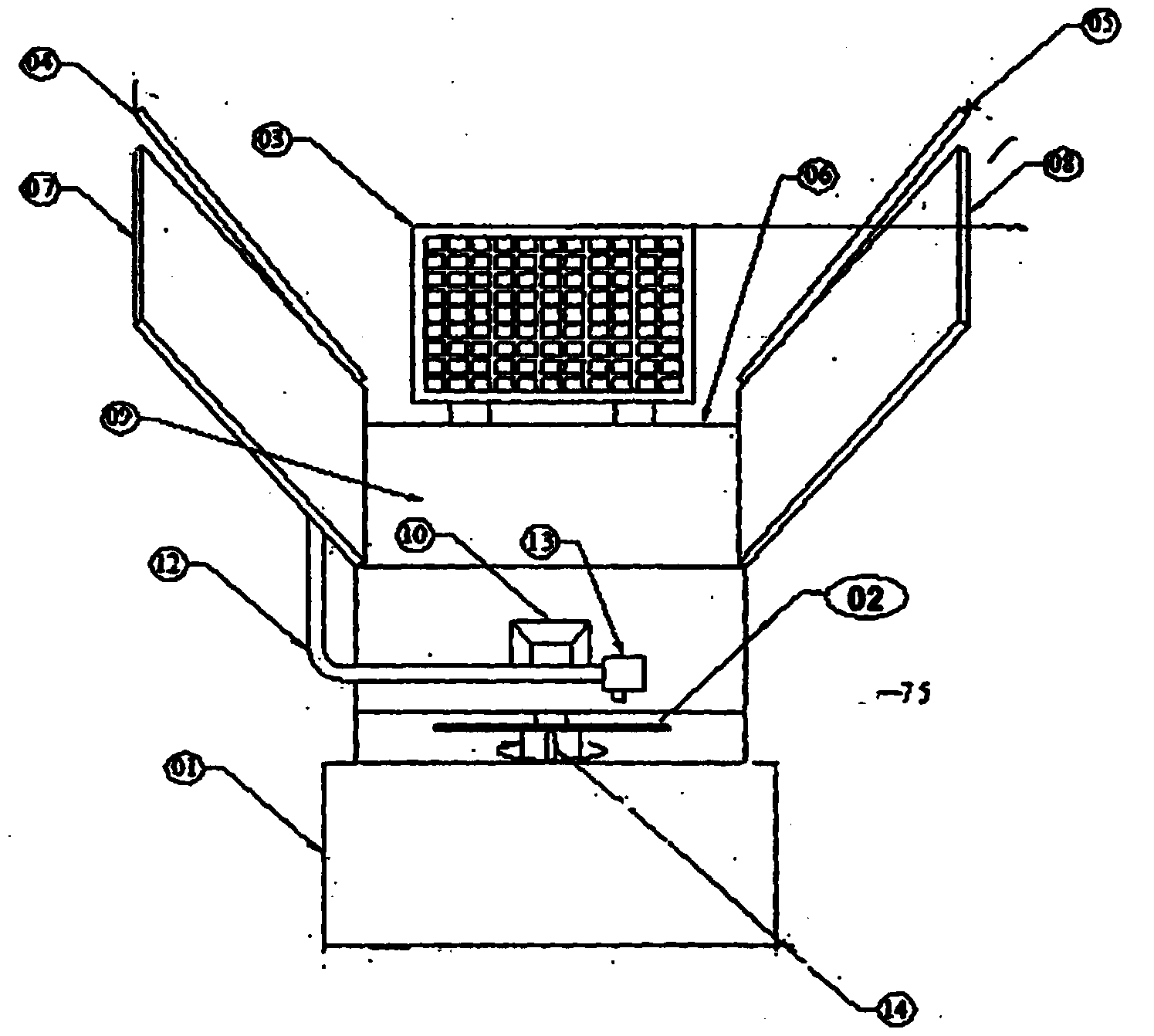

[0098]selected in a situation Figure 1-Figure 7 The solar drier in the one does not have any reflector, in the other case there is a reflector on the collector side. Measurements were taken under nearly identical ambient conditions on two typical days in March, and dry air temperatures recorded from 11 am to 4:30 pm are listed in Table 1.

[0099] Table 1: Drying air temperature distribution inside the unit with and without reflectors

[0100]

[0101]

[0102] This example tells us that using reflectors on the collector side improves the dry air temperature distribution over the day.

example 2

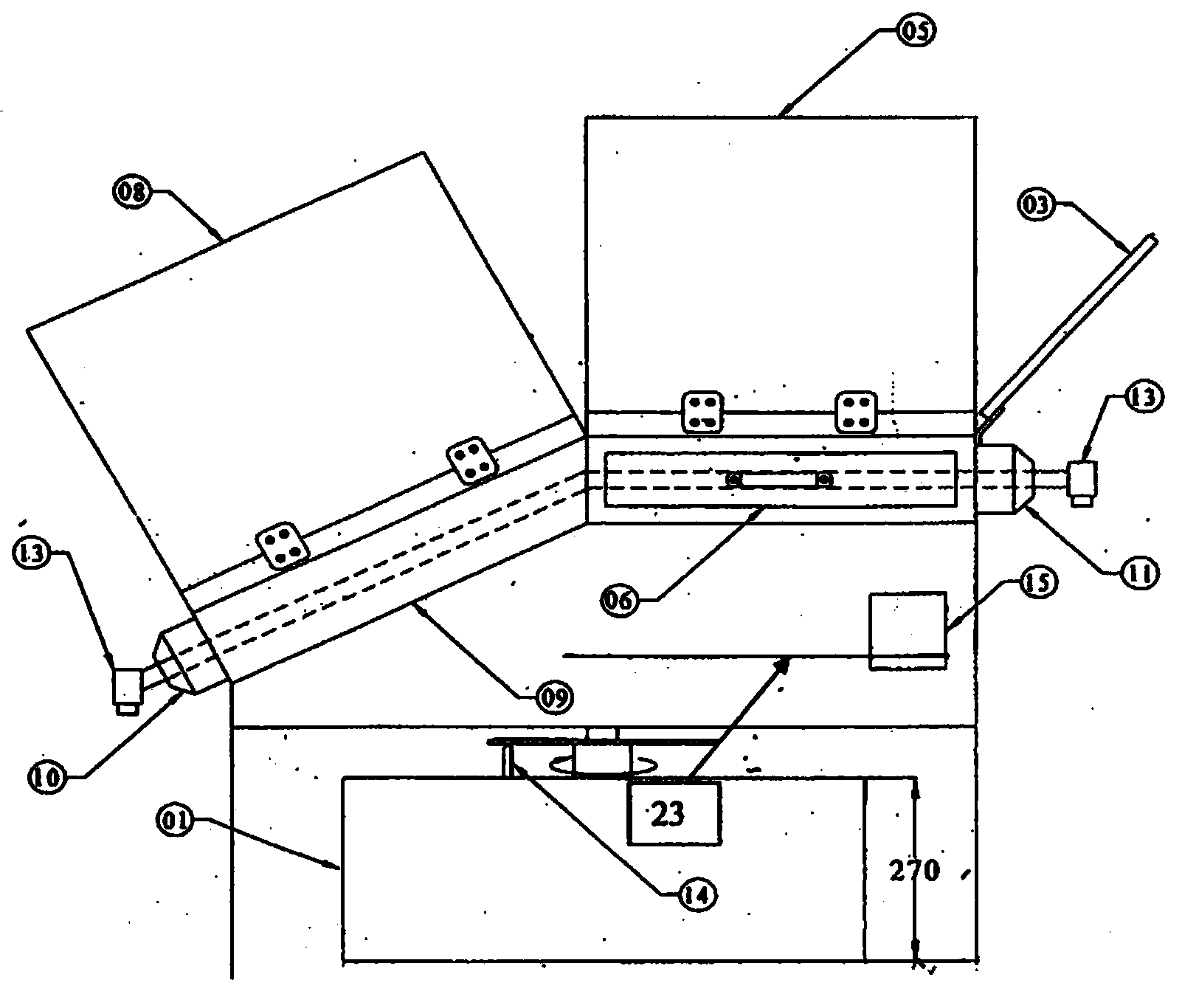

[0104] The DC fan runs directly using 10 watt solar PV panels. The table below shows the fan speed in r.p.m as measured by the tachometer based on the variation in sun intensity for that particular day. Because the wind turbines are powered by solar PV panels, as the sun's intensity increases, the power output from the panels increases, which increases the speed of the wind turbines. Data was collected without a reflector on the dry chamber.

[0105] Table 2: Variation of fan speed with solar intensity and calculated mass flow of air inside the dryer

[0106] time (h)

[0107] 14:00

[0108] This example tells us that the fans are also running at very high speeds during peak insolation. This effect is beneficial for the drying process as it helps to control the temperature inside the drying chamber so that during times of high solar insolation the increased wind flow within the unit does not reach very high stagnation temperatures. This can be verified w...

example 3

[0110] The experiments in Example 2 were repeated on two similar solar dryers. In one case, the fan speed was fixed at 2700 rpm, while in the other case, the fan speed was varied with solar insolation. In the table below, for the two cases, the collector outlet temperature T co (°C) are plotted as a function of time of day.

[0111]

[0112] The above example tells us that when the fan speed is fixed, T co varies from 62.1°C to 90°C, and by using a fan directly connected to the PV panel, T co is better controlled and is in the range of 72.3°C to 83.2°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com