Production method of resistor

A production method and technology of resistors, applied in the direction of resistors, resistor manufacturing, circuits, etc., can solve problems such as burnout, insulation sleeve burnout, breakdown grounding, short-circuit tripping, etc., so as to improve the operating life and reduce the failure rate , The effect of improving the overcurrent capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

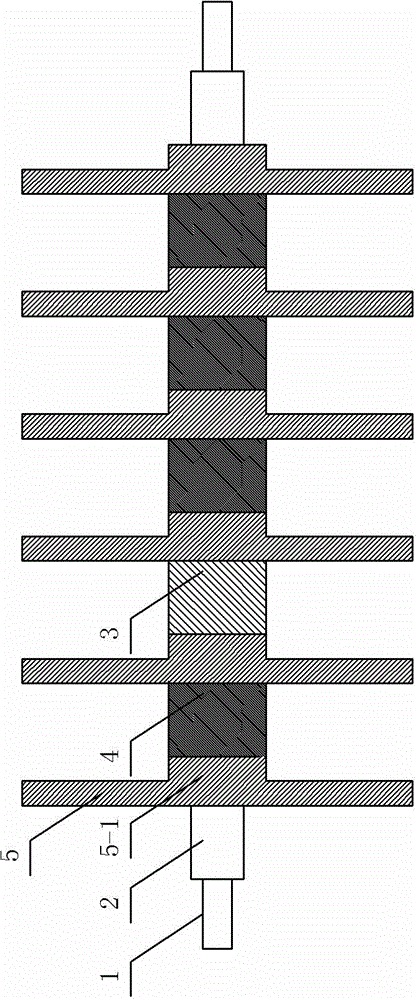

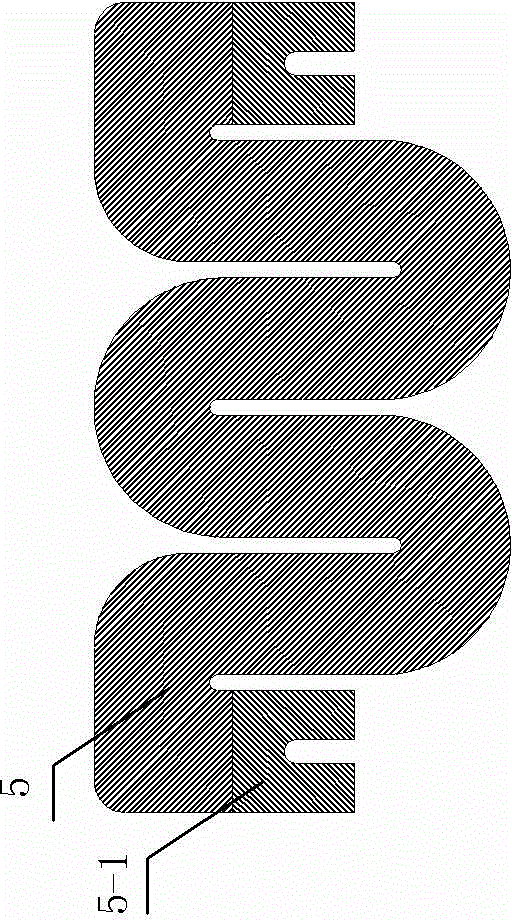

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0020] figure 1 , figure 2 and image 3 The production method of the resistor shown is carried out in the following steps:

[0021] (1) Insert insulating sleeves 2 on the outer sides of the two supporting rods 1 arranged side by side;

[0022] (2) Connect the two ends of the first resistance sheet 5 to one end of the two insulating sleeves 2 respectively;

[0023] (3) Put the metal beads 4 on the two insulating sleeves 2 along one side of the first resistance piece 5, and make the contact surface of one end of the metal bead 4 and the contact surface 5-1 of the resistance piece 5 side abutment;

[0024] (4) On the two insulating sleeves 2, insert a second resistance piece 5 along the other end of the metal bead 4, one side of the second resistance piece 5 abuts against the contact surface of the other end of the metal bead 4;

[0025] (5) On one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com