Civil engineering material volume change test instrument and test method

A technology of volume change and geotechnical materials, applied in the direction of material thermal expansion coefficient, etc., can solve the problems that the volume change of geotechnical materials cannot be measured, and achieve the effect of reducing influence, reducing test error and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

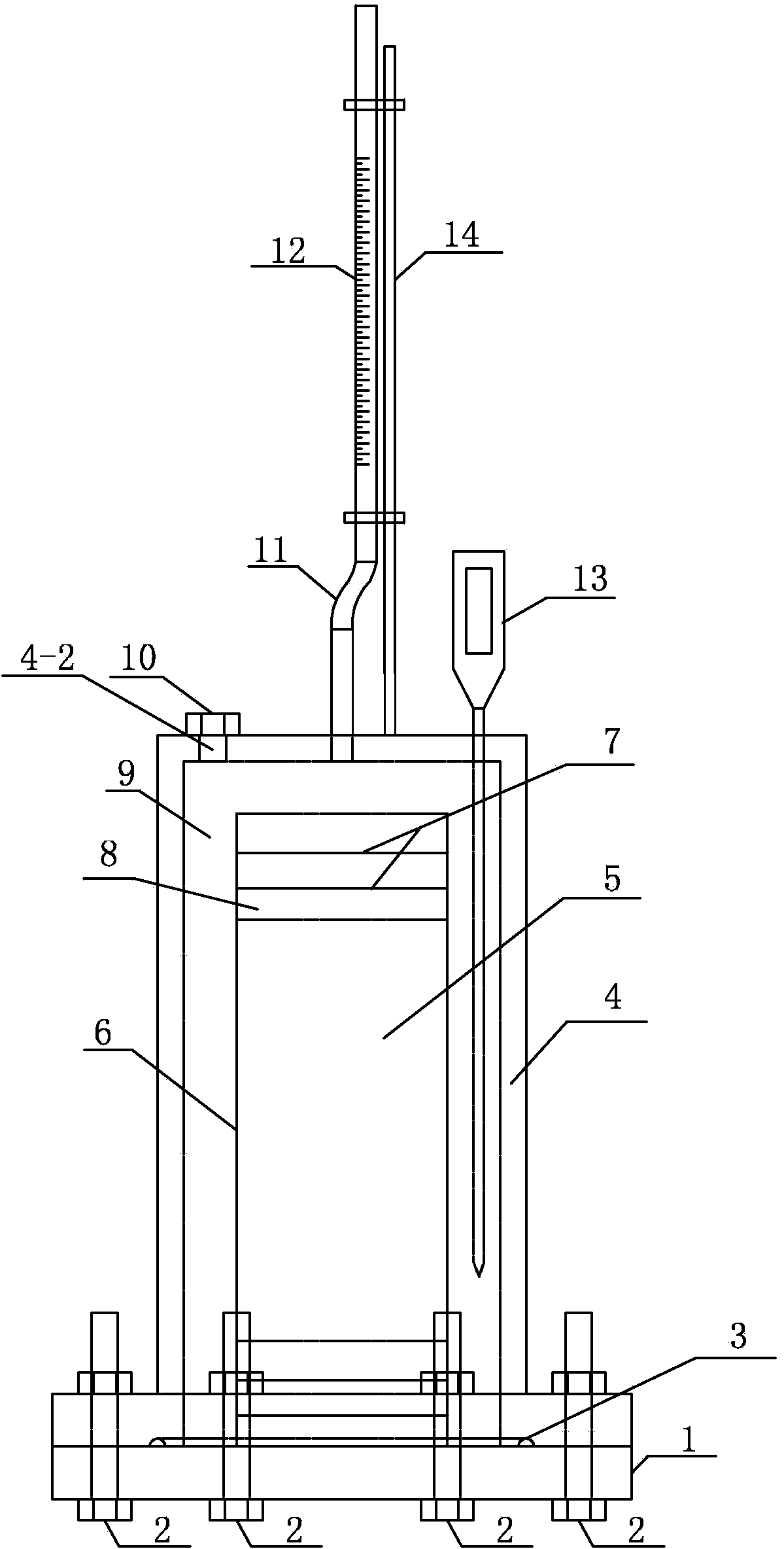

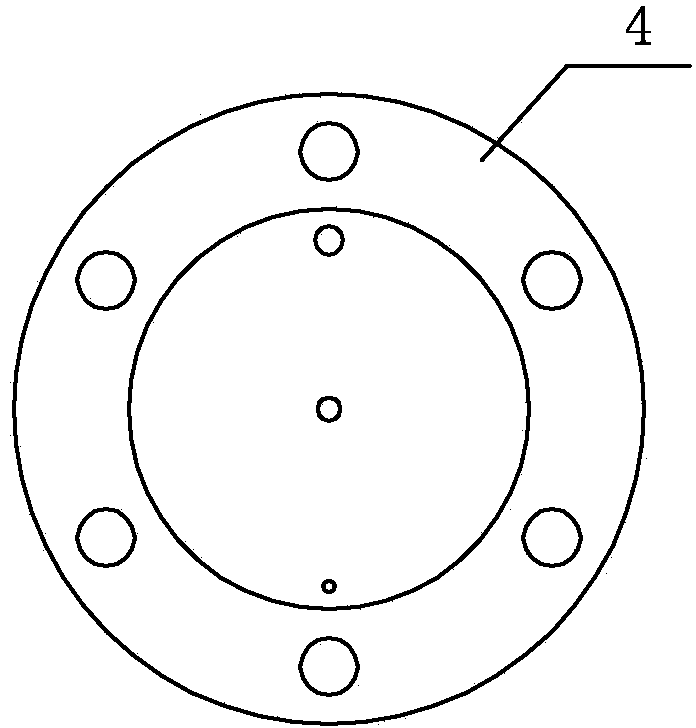

[0041] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, this embodiment includes a base 1, a sealing rubber ring 3, an upper cover 4, a sealing screw 10, a plastic tube 11, a scale glass tube 12, a probe thermometer 13 and a fixing frame 14, and the base 1 consists of a boss 1- 1 and the bottom plate 1-2, the boss 1-1 is set at the center of the upper end surface of the bottom plate 1-2, the boss 1-1 is integrated with the bottom plate 1-2, the upper cover 4 is barrel-shaped, and the upper cover 4 There is an annular groove 4-1 on the edge of the center hole of the lower end surface, the sealing rubber ring 3 is set in the annular groove 4-1, the upper cover 4 is fastened on the base 1, and the upper cover 4 is connected to the base 1 by four fastening screws 2. The base 1 is connected, the top of the upper cover 4 is provided with an air intake and exhaust hole 4-2, the threaded hole 9 can be used for water or air intake, the sealing s...

specific Embodiment approach 2

[0042] Specific implementation mode two: combination figure 1 Describe this implementation mode, this implementation mode is realized through the following steps:

[0043] Step 1, preparing the geotechnical material test piece: making the geotechnical test piece 5 into a cylindrical shape;

[0044] Step 2, calculate the volume of geotechnical specimen 5 before testing: calculate the volume of geotechnical specimen 5 according to geotechnical specimen 5 diameters and height, also can adopt the volume of geotechnical specimen 5 to record by wax seal drainage method, obtain by two ways The volume of V is denoted as V 0 ;

[0045] Step 3, install the geotechnical test piece 5: place the geotechnical test piece 5 on the boss 1-1, place the stopper 8 on the upper end surface of the geotechnical test piece 5, and use the waterproof rubber mold 6 to place the stopper 8 and the geotechnical test piece 5 and the cylindrical surface of the boss 1-1 are completely wrapped, and the rubb...

specific Embodiment approach 3

[0056] Specific implementation mode three: combination figure 1 Describe the present embodiment. In the present embodiment, the diameter of the geotechnical test piece 5 in step 1 is φ40mm±2mm, and the height is 50mm˜90mm. Other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com