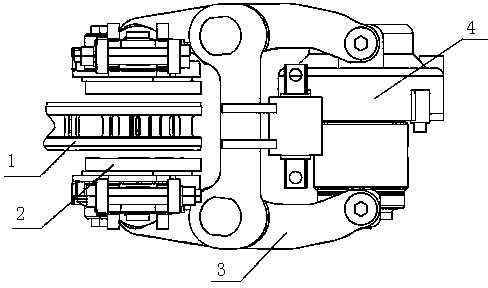

Motor train unit foundation brake device suitable for high and cold environment

A technology of basic braking devices and EMUs, applied in the direction of brake discs, brake types, railway braking systems, etc., can solve the problems of increasing maintenance workload and operating costs, a large number of manpower, material resources, financial resources, etc., and achieve improvement The effect of vehicle utilization, prevention of snow and ice accumulation on the surface, reduction of maintenance workload and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

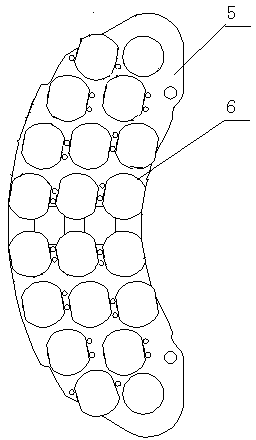

[0019] The bilateral gap between the brake disc and the brake pad is 3 mm, and the gap between the friction particles in the main friction area of the brake pad is 6.3 mm.

Embodiment 2

[0021] The bilateral gap between the brake disc and the brake pad is 5 mm, and the gap between the friction particles in the main friction area of the brake pad is 8 mm.

Embodiment 3

[0023] The bilateral gap between the brake disc and the brake pad is 6mm, and the gap between the friction particles in the main friction area of the brake pad is 5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com