Wind turbine system and electricity generation method thereof

A technology of wind power generation system and generator, applied in the direction of wind power generation, wind power engine, wind power motor combination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

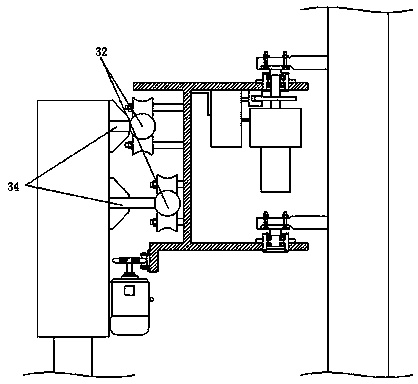

[0043] Such as figure 2 It is a schematic structural diagram of the wind power generator system in Embodiment 1 of the present invention. A gyrotron with a length of 2,000 meters and a radius of gyration of 100 meters, other positions are straight lines, the length direction of the gyrotron is in the windward direction, the height of the gyrotron is designed to be 20 meters, the total length of the blades is 23 meters, and the width is 2 meters. The number of cars is about 250-350, as long as the power reaches nearly 40 megawatts when the wind direction is not parallel to the straight line and reaches 13 m / s.

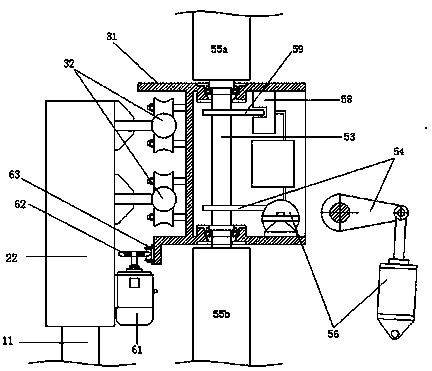

[0044] image 3 It is a schematic diagram of the connecting structure of the blade and the trolley of the present invention. The blade in the figure is a whole. The blade is connected to the upper and lower rotating shafts 53 of the blade through the upper and lower blade handles 51, and then through the blade angle servo system 56 The control vane 55 rotates at a de...

Embodiment 2

[0054] Such as Figure 11 It is a schematic structural diagram of the vertical wind power generator system of Embodiment 2. In the picture, there is a polygonal gyroscopic body with a length of 2000 meters. The length direction of the gyroscopic body faces the wind. The height of the gyroscopic body is designed to be 20 meters. The total length of the blades is 23 meters, and the width is 2 meters. The number of trolleys is about 250-350. The power reaches nearly 40 megawatts as long as the wind direction is not parallel to the straight line direction and reaches 13 m / s. The device in Example 2 is the same as that in Example 1.

Embodiment 3

[0056] A circular gyratory body with a diameter of 2000 meters, the height of the gyratory body is designed to be 20 meters, the total length of the blades is 23 meters, and the system is 2 meters wide. The number of trolleys is about 400-450, and the wind speed reaches 13 meters per second. When and in any wind direction, the power reaches nearly 35 megawatts. The device in Example 3 is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com