Immobilized microorganism oil-spilling repairing agent and preparation method

A technology for immobilizing microorganisms and repairing agents, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of difficulty in forming polyvinyl alcohol balls, reducing microbial activity, and low mechanical strength of preparations, achieving high Microbial activity and cell capacity, enhanced tolerance, good stability and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

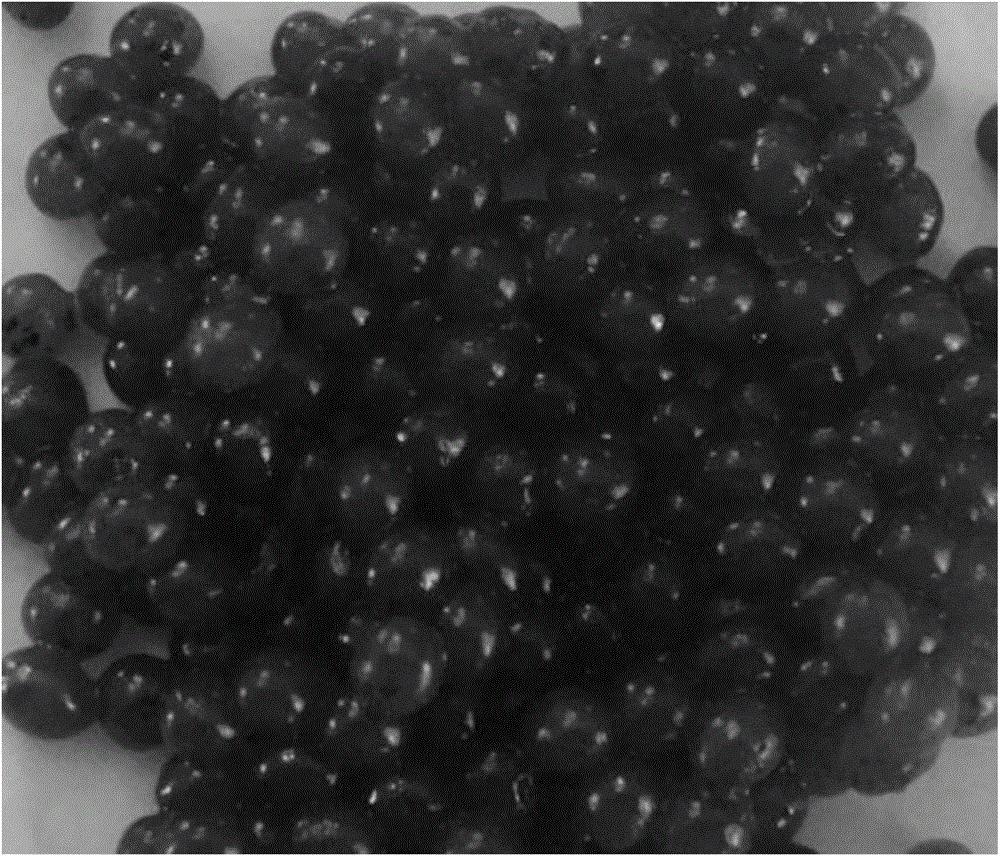

Image

Examples

Embodiment 1

[0040] A preparation method of an immobilized microbial oil spill restoration agent using sodium alginate-calcium chloride-modified mussel shells as an embedded and immobilized material, the specific steps are:

[0041] 1. Preparation of modified mussel shells

[0042] 1) Cleaning, sieving, drying and pulverizing the raw mussel shells, passing through an 80-mesh sieve, and setting aside;

[0043] 2) Weigh the mussel shells crushed above, and add the citric acid solution with a mass fraction of 2.5%, wherein the mass ratio of the mussel shells to the citric acid solution is 1:2, stir and mix, and mix the mixed feed solution in Immerse at room temperature for about 1.5h;

[0044] 3) Put the impregnated material liquid into a high-temperature muffle furnace, raise it from room temperature to the required activation temperature of 550° C., and keep the temperature at a rate of 50° C. / min for 30 minutes.

[0045] 4) The activated sample is taken out from the muffle furnace and co...

Embodiment 2

[0056] A preparation method of an immobilized microbial oil spill restoration agent using sodium alginate-calcium chloride-modified mussel shells as an embedded and immobilized material, the specific steps are:

[0057] 1. Preparation of modified mussel shells

[0058] 1) Cleaning, screening, drying and pulverizing the raw mussel shells, passing through a 40-mesh sieve, and setting aside;

[0059] 2) Take the mussel shells that have been crushed, and add them to a citric acid solution with a mass fraction of 5%, wherein the mass ratio of the mussel shells to the citric acid solution is 1:1, stir and mix, and put the mixed feed solution in Immerse at room temperature for about 2.0h;

[0060] 3) Put the impregnated material liquid into a high-temperature muffle furnace, raise it from room temperature to the required activation temperature of 300° C., and keep the temperature at a rate of 60° C. / min for 30 minutes.

[0061] 4) The activated sample is taken out from the muffle f...

Embodiment 3

[0072] A preparation method of an immobilized microbial oil spill restoration agent using sodium alginate-calcium chloride-modified mussel shells as an embedded and immobilized material, the specific steps are:

[0073] 1. Preparation of modified mussel shells

[0074] 1) Cleaning, sieving, drying and pulverizing the raw mussel shells, passing through an 80-mesh sieve, and setting aside;

[0075] 2) Take the crushed mussel shells and add them to a citric acid solution with a mass fraction of 2%, wherein the mass ratio of the mussel shells to the citric acid solution is 1:3, stir and mix, and put the mixed feed solution in Immerse at room temperature for about 1.0h;

[0076] 3) Put the impregnated material liquid into a high-temperature muffle furnace, raise it from room temperature to the required activation temperature of 600° C., and keep the temperature at a rate of 50° C. / min for 15 minutes.

[0077] 4) The activated sample is taken out from the muffle furnace and cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com