Method for extracting m-phthalic acid-5-sodium sulfonate from ternary-monomer industrial waste water

A technology for the production of isophthalic acid and wastewater, which is applied in chemical instruments and methods, preparation of organic compounds, purification of alkali metal sulfite/sulfate, etc., and can solve problems such as high cost, economic loss, and loss of useful components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

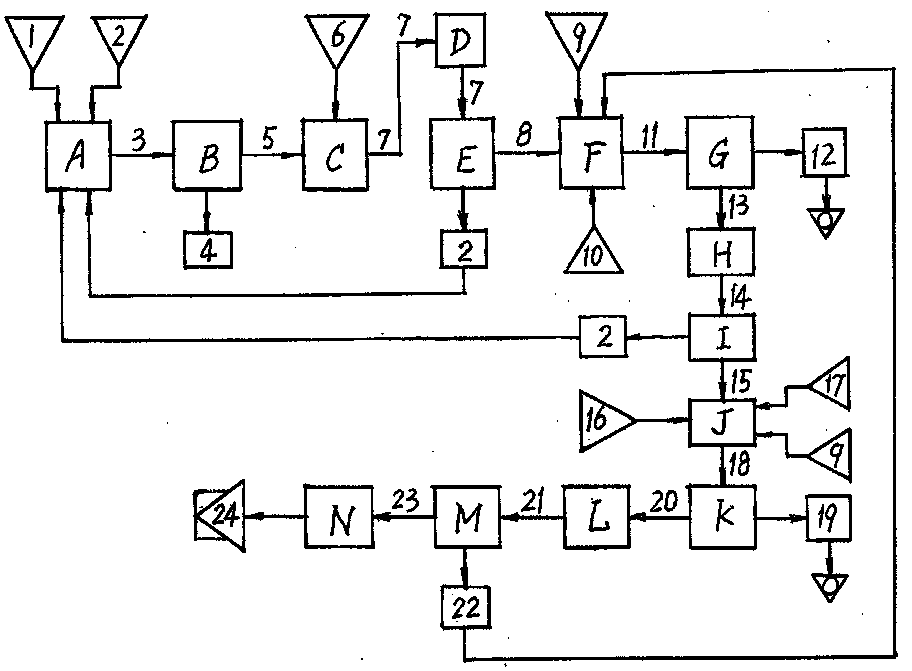

[0008] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0009] refer to figure 1 , the method for extracting isophthalic acid-5-sodium sulfonate from three-monomer production wastewater consists of precipitation crystallization tank A, filter press B, ester decomposition tank C, high-pressure pump D, distillation tower E, decolorization and miscellaneous absorption still F, filter G, concentrated crystallization kettle H, centrifugal dehydrator I, thermal melting kettle J, fine filter K, secondary concentration crystallization kettle L, rubber-lined dehydrator M, and dryer N are connected by pipelines to form a production line, with three single Solid production wastewater 1 is used as the main raw material, after precipitation and crystallization and press filtration process, ester decomposition and distillation process, decolorization and impurity removal and filtration process, concentration crystallizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com