Method for purifying cyclohexanone through distillation adsorption

A cyclohexanone and adsorbent technology, applied in chemical instruments and methods, other chemical processes, separation/purification of carbonyl compounds, etc. value, the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0039] Preparation Example 1: Treatment of Adsorbent

[0040] Treat the sorbent as follows:

[0041] a) Modification of 4A molecular sieve: add conventional 4A molecular sieve to excess sodium hydroxide solution with a concentration of 0.02mol / L, heat and stir in an oil bath at 85°C for 5h, filter with suction, and rinse with deionized water until neutral , place the obtained sample in a 90°C oven to dry;

[0042] Then the dried 4A molecular sieve was used with 0.02mol / L NH 4 NO 3 The solution was soaked with a solid-to-liquid ratio of 1:15, that is, 15 mL of ammonium nitrate solution per 1 g of 4A molecular sieve, stirred for 5 h under heating in an oil bath at 85 ° C, and then suction filtered and washed. This process was repeated three times;

[0043] After the finally obtained 4A molecular sieve was placed in an oven at 90°C for 5h, it was roasted in a muffle furnace at 550°C for 6h, and after cooling, the 4A molecular sieve used in the above step 2) was obtained;

[0...

Embodiment 1

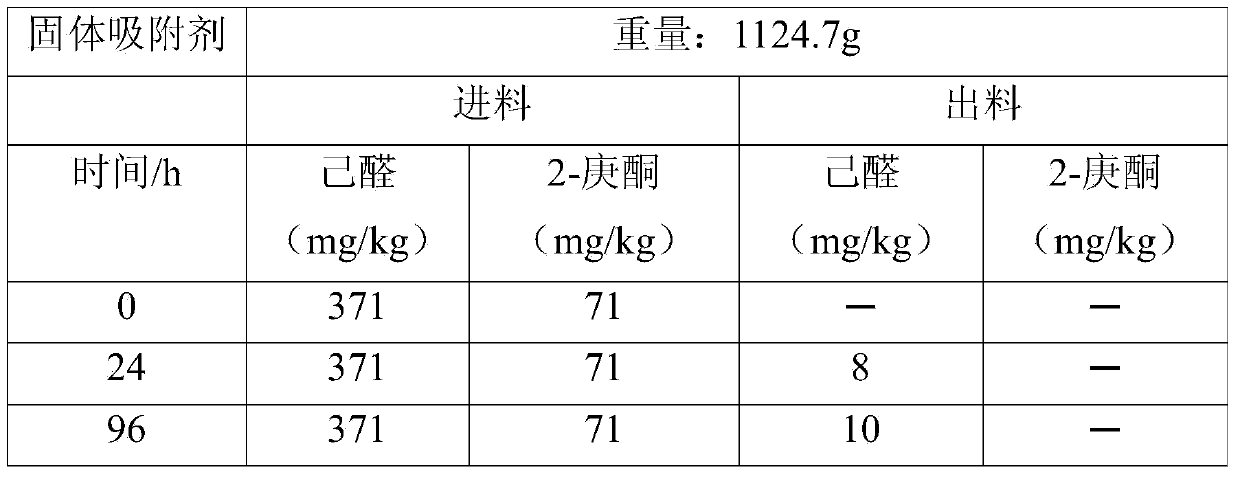

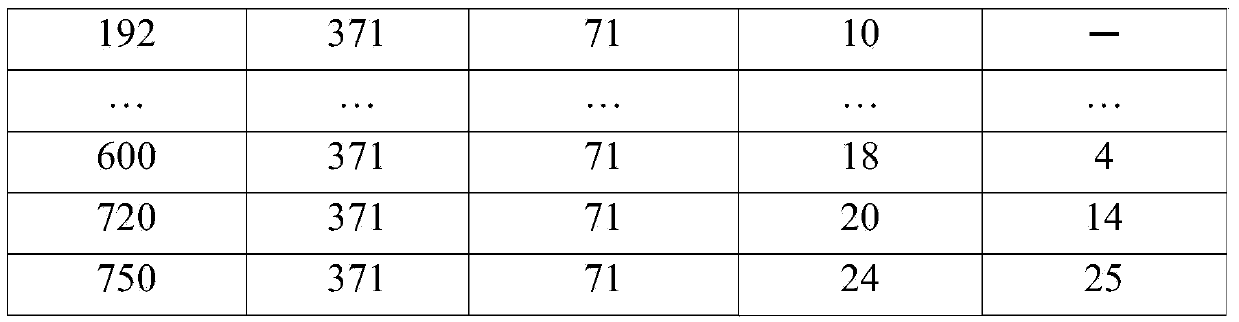

[0050] In the four adsorption columns (each adsorption column specification: column height 200mm, internal diameter 50mm, volume 0.39L) are respectively filled with 299.48g of activated alumina with an outer diameter of 2 to 3mm prepared in Preparation Example 1; 297.28g of 4A molecular sieve with a diameter of ~3mm; 264.38g of silica gel with an outer diameter of 3~5mm; According to distillation temperature 230℃, adsorption temperature 50℃, adsorption pressure 0.7MPa, liquid space velocity 2.0hr -1 Under the technological conditions of the present invention, the cyclohexanone raw material (the content of hexanal is 371mg / kg, and the content of 2-heptanone is 71mg / kg) before the secondary saponification is first passed through the distiller, and then passed through the adsorption column. The content of the impurity (hexanal and 2-heptanone) of cyclohexanone before and after treatment is shown in Table 2.

[0051] Table 2.

[0052]

[0053]

[0054] Note: "─" indicates ...

Embodiment 2

[0063] In four adsorption columns (each adsorption column specification: column height 200mm, inner diameter 50mm, volume 0.39L), fill successively according to the activated alumina 297.32g of outer diameter 2-3mm prepared in the preparation example 1; 295.58g of 3mm 4A molecular sieve; 270.38g of silica gel with an outer diameter of 3-5mm and 293.64g of bar-shaped 4A molecular sieve, a total of 1156.9g of four kinds of adsorbents. According to distillation temperature 230°C, adsorption temperature 50°C, adsorption pressure 0.7MPa, liquid space velocity 2.5hr -1 Under the technological conditions of the present invention, the cyclohexanone raw material (hexanal content is 290mg / kg, 2-heptanone content is 69mg / kg) before the secondary saponification is first passed through the distiller, and then passed through the adsorption column. The content of the impurity (hexanal and 2-heptanone) of cyclohexanone before and after treatment is shown in Table 4.

[0064] Table 4.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com