How to adjust the ph value of boiler water

A boiler furnace and boiler water technology, applied in the chemical industry, can solve the problems of poor control of alkali addition, failure to achieve a gentle upward trend of the dotted line, alkaline corrosion of the boiler drum and the boiler body, etc., and avoid pH fluctuations. Large, fast and effective operation, good corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

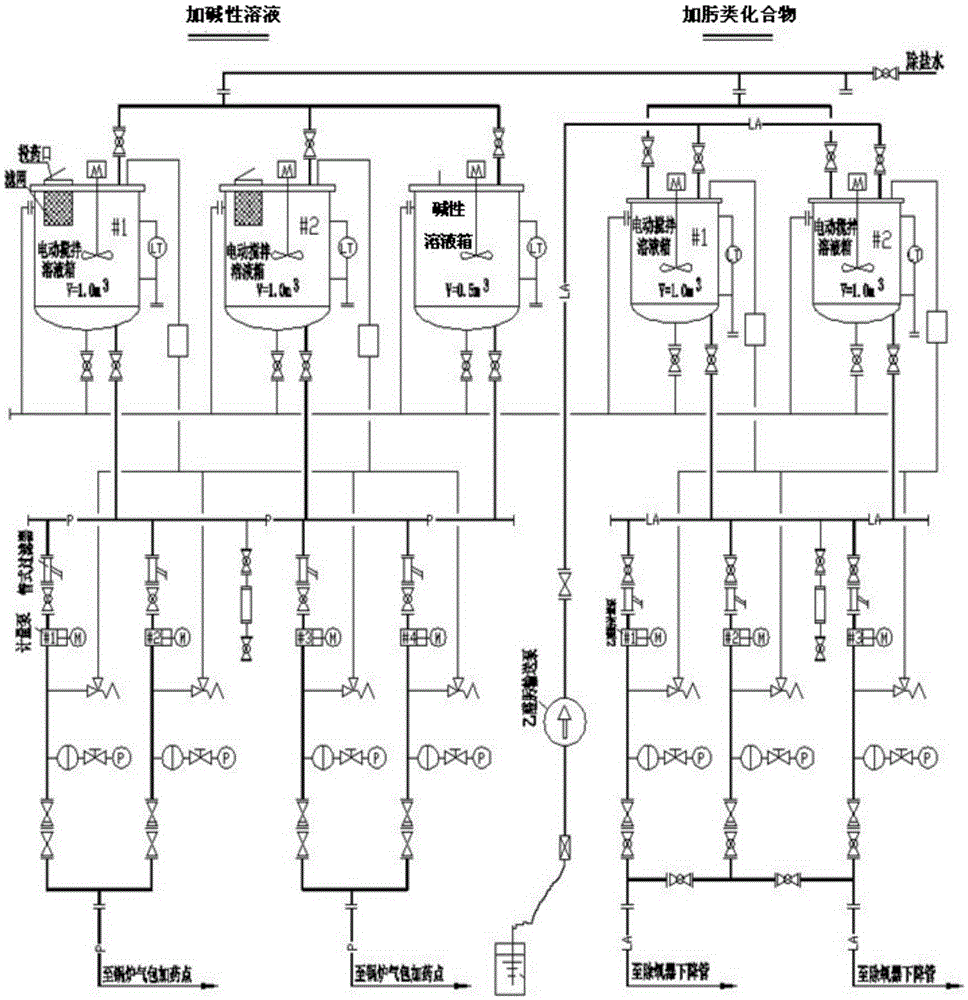

[0038] The 2# boiler water in the thermal power center was polluted by organic matter, and the online pH meter dropped from the normal 9.5 to 4.73. A dosing system with three first dosing metering boxes and two second dosing metering boxes was adopted, such as figure 1 shown.

[0039] Adding concentration is the sodium hydroxide solution of 3.5wt% in 3 first dosing metering boxes respectively, and adding concentration is respectively the acetaldehyde oxime solution of 4wt% in the second dosing metering box, by dosing pump in boiler steam Sodium hydroxide solution is added to the inlet of the dosing point of the package, and acetaldehyde oxime aqueous solution is added to the inlet of the boiler feed water dosing point. The water online pH meter controls the pH value of the boiler water to achieve a gentle rising trend of the curve. Wherein the volume of the alkaline solution added by the first dosing metering box accounts for 2% of the total volume of the boiler water, and th...

Embodiment 2

[0043] The 2# boiler water in the thermal power center was polluted by organic matter, and the online pH meter dropped from the normal 9.5 to 6.2. A dosing system with three first dosing metering boxes and two second dosing metering boxes was adopted, such as figure 1 shown.

[0044] Adding concentration is the sodium hydroxide solution of 2.5wt% in 3 first dosing metering boxes respectively, and adding concentration is the acetaldehyde oxime solution of 3wt% respectively in the second dosing metering box, by dosing pump in boiler steam Sodium hydroxide solution is added to the inlet of the dosing point of the package, and acetaldehyde oxime aqueous solution is added to the inlet of the boiler feed water dosing point. The water online pH meter controls the pH value of the boiler water to achieve a gentle rising trend of the curve. Wherein the volume of the alkaline solution added by the first dosing metering box accounts for 1% of the total volume of the boiler water, and the...

Embodiment 3

[0048] The operation is the same as in Example 1, the difference is as follows: respectively adding a concentration of 2wt% sodium hydroxide solution to the first 3 dosing metering boxes, and adding a concentration of 2.5wt% to the second dosing metering box respectively The methyl ethyl ketone oxime solution, wherein the volume of the alkaline solution added by the first dosing metering box accounts for 2% of the total volume of boiler water, and the volume of the acetaldehyde oxime solution added by the second dosing metering box accounts for 2.5% of the total volume of boiler furnace water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com