Preparation method of lithium silicate porous material used for absorption of high temperature CO2

A porous material, lithium silicate technology, applied in the field of preparation of lithium silicate porous materials, can solve problems such as lithium silicate porous materials that have not yet been seen, and achieve the effects of avoiding ball milling and calcination, reducing emissions, and reducing CO2 emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Lithium nitrate 0.4mol is dissolved in the mixed solvent 80ml that contains ethanol 55vol% ethanol and water, configuration molar concentration is the lithium nitrate solution of 5mol / L, then adds the citric acid of 0.07mol, stirs to obtain solution A; Add lithium nitrate and Add 0.1mol tetraethyl orthosilicate dropwise to the clear solution of citric acid and stir to obtain solution B; heat and stir the above solution B at 60°C for two hours to promote the hydrolysis of tetraethyl orthosilicate and complete the sol-gel transformation at the same time to obtain jelly shaped gel; put the gel in an oven, age at 70°C for 12 hours, and then dry at 120°C for 15 hours to obtain a xerogel precursor; grind the xerogel precursor into powder, then press it into a Lithium silicate porous material is obtained after medium ignition and combustion.

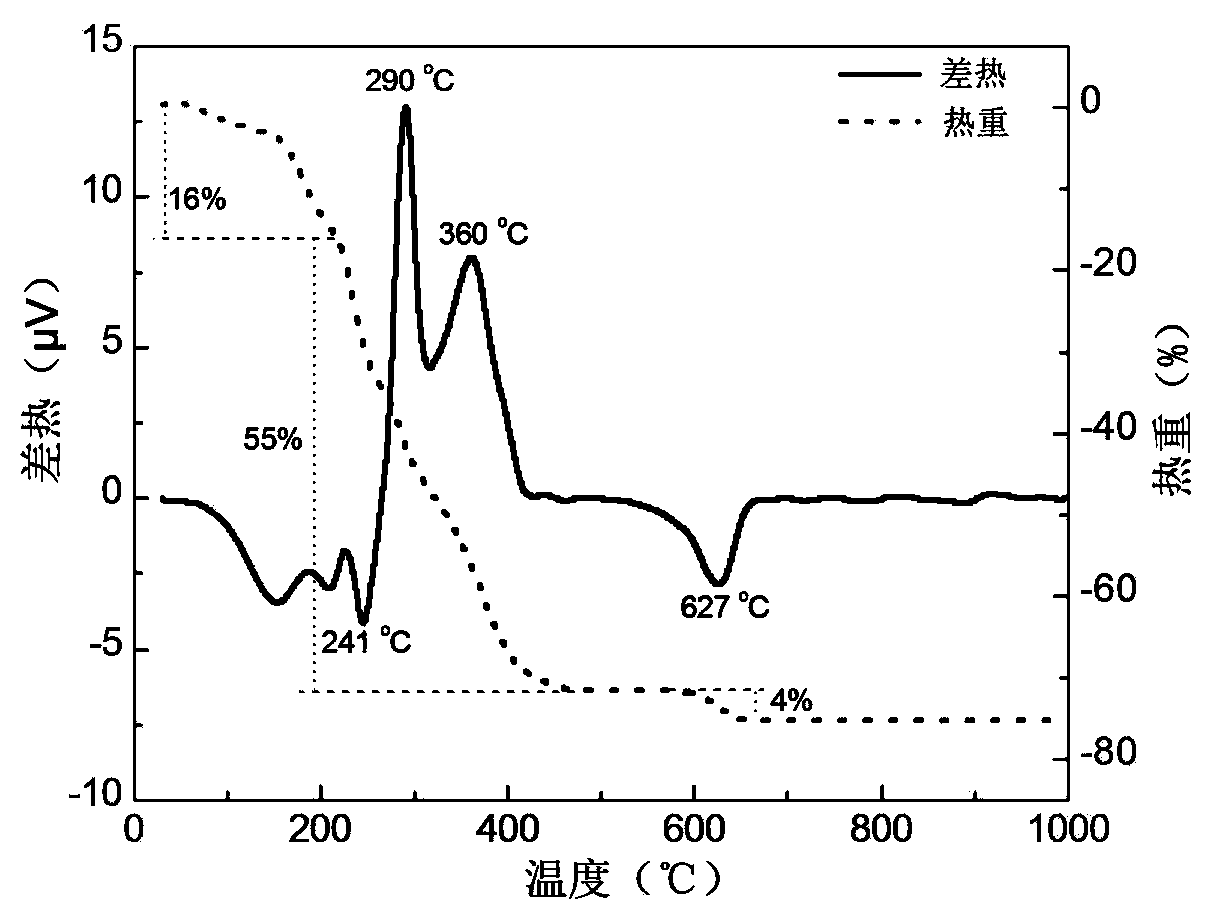

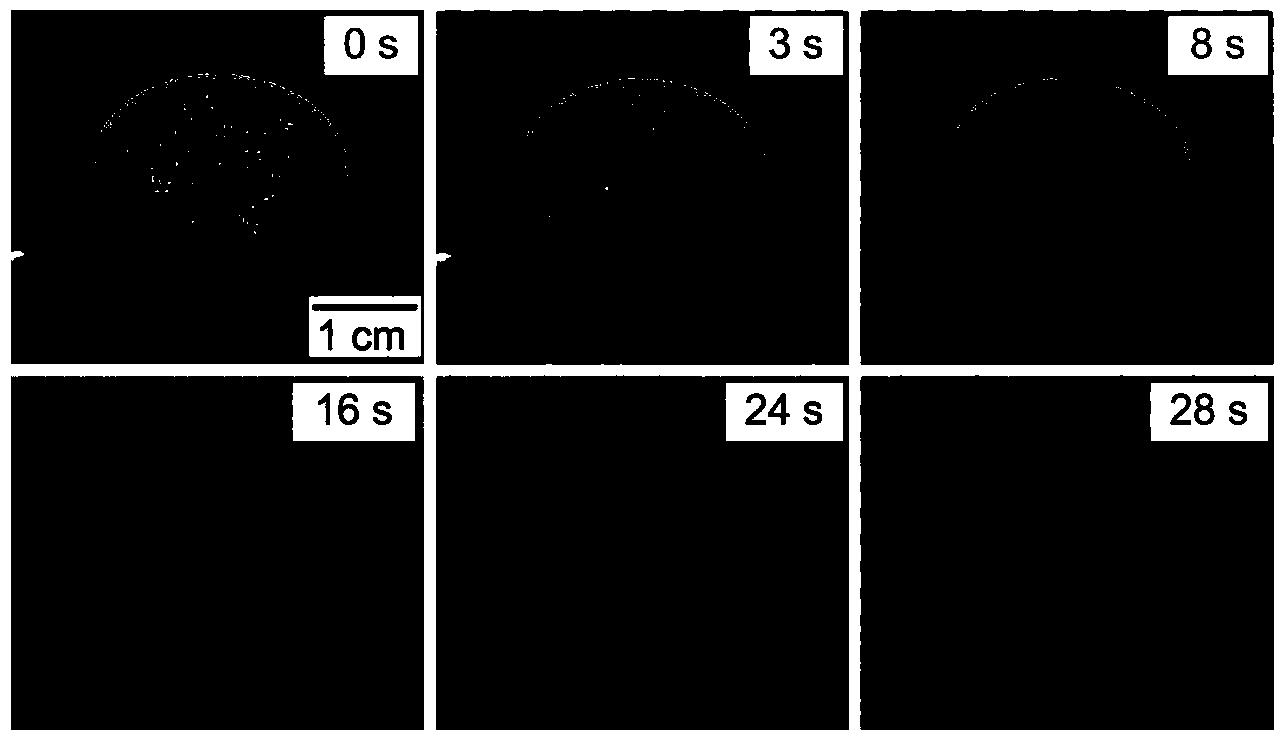

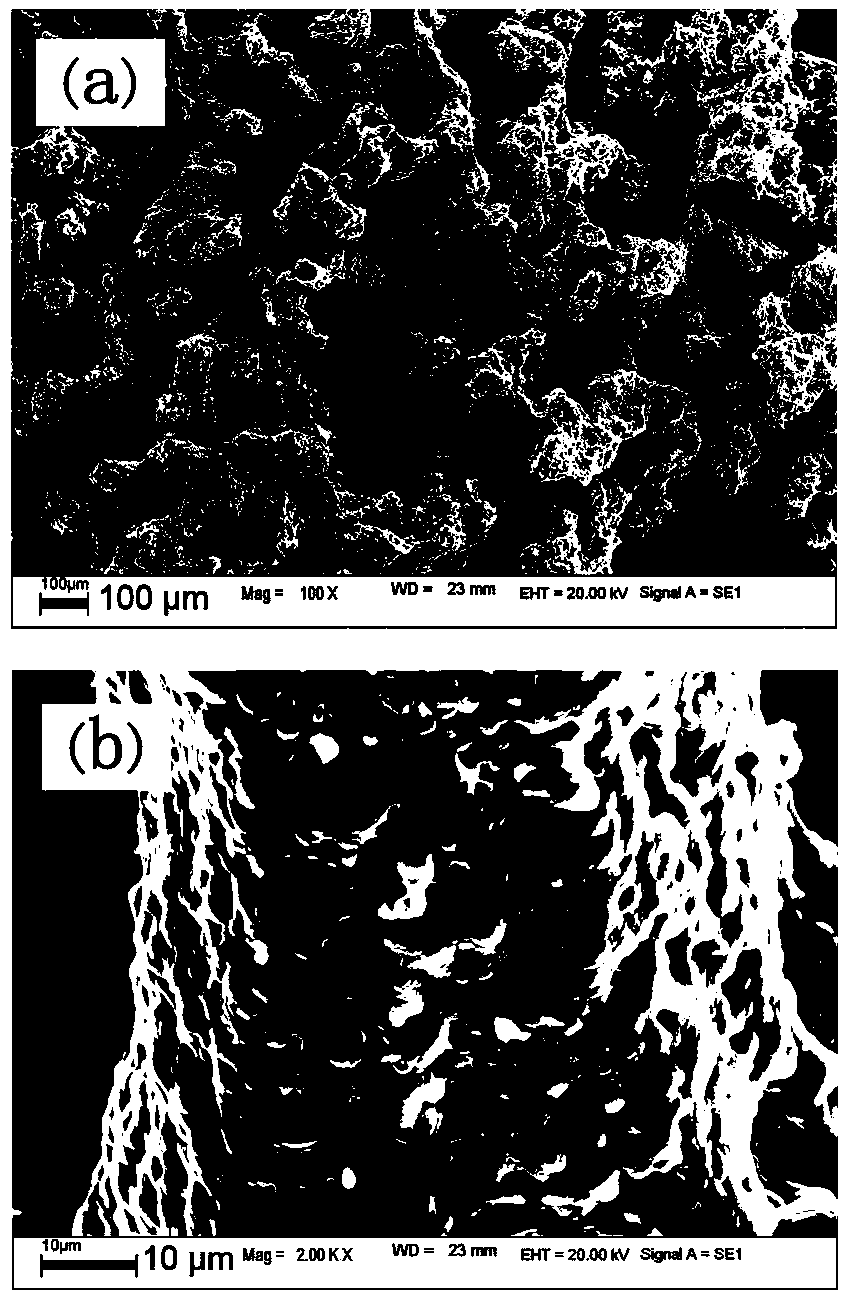

[0043] The thermogravimetric-differential thermal analysis results of the xerogels are found in figure 1 ,from figure 1 It can be see...

Embodiment 2

[0046] Dissolve 0.4 mol of lithium nitrate in 80 ml of a mixed solvent of ethanol and water containing 55 vol % of ethanol, configure 2 parts of lithium nitrate solutions with a molar concentration of 5 mol / L, add 0.05 mol and 0.1 mol of citric acid respectively, stir to obtain clarification Solution, other technological process and process parameter are with implementing example 1.

[0047] Carry out CO under the same condition as embodiment example 1 2 Adsorption test shows that the absorption rates are 26.5% and 24.2%, respectively.

Embodiment 3

[0049] Referring to the configuration of 3 parts of solution B in Example 1, the hydrolysis and sol-gelation processes were carried out at 40°C, 50°C and 70°C respectively. The corresponding hydrolysis time is shown in Table 1. Other technological process and technological parameter are with implementing example 1.

[0050] Carry out CO under the same condition as embodiment example 1 2 Adsorption test, the measured absorption rate is shown in Table 1.

[0051] Table 1 CO of products at different hydrolysis and sol-gelation temperatures 2 Absorption rate

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com