Vertical type circular seam automatic pipe welder

An automatic welding and vertical technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of narrow application range, low machining accuracy, limited radius, etc., achieve simple and reasonable structure setting, improve machining accuracy, guarantee full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

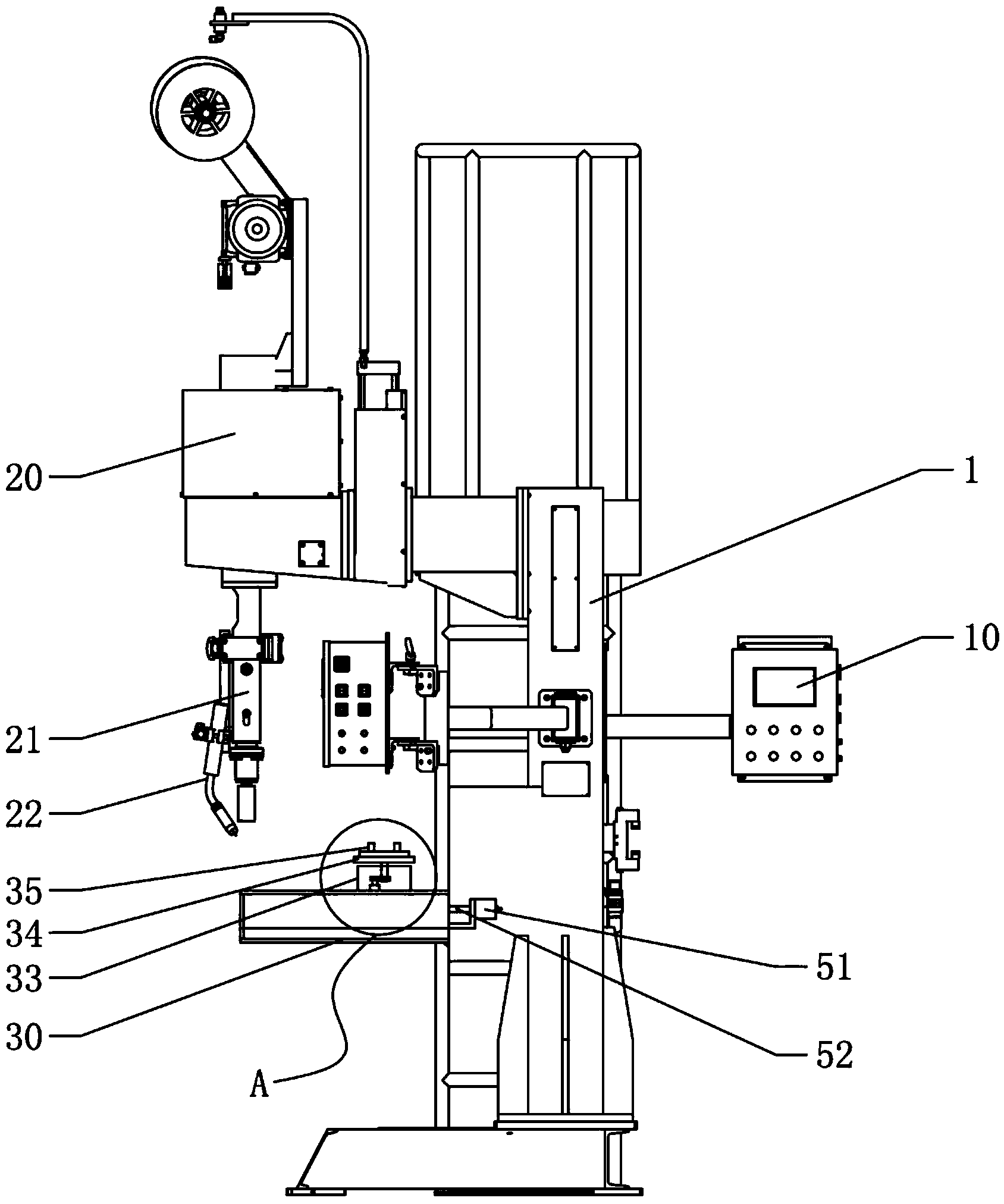

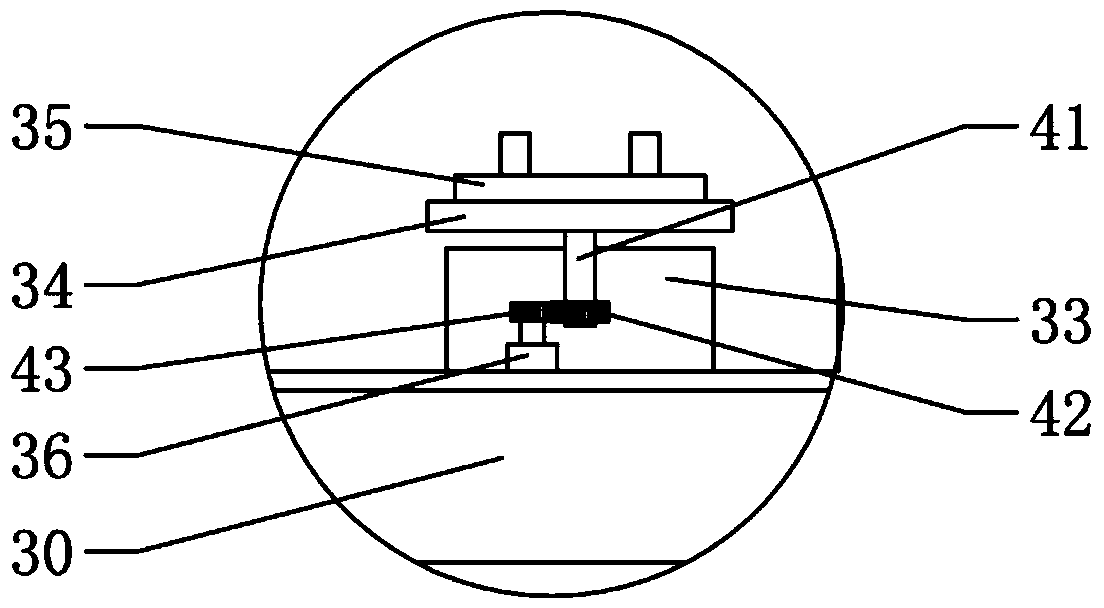

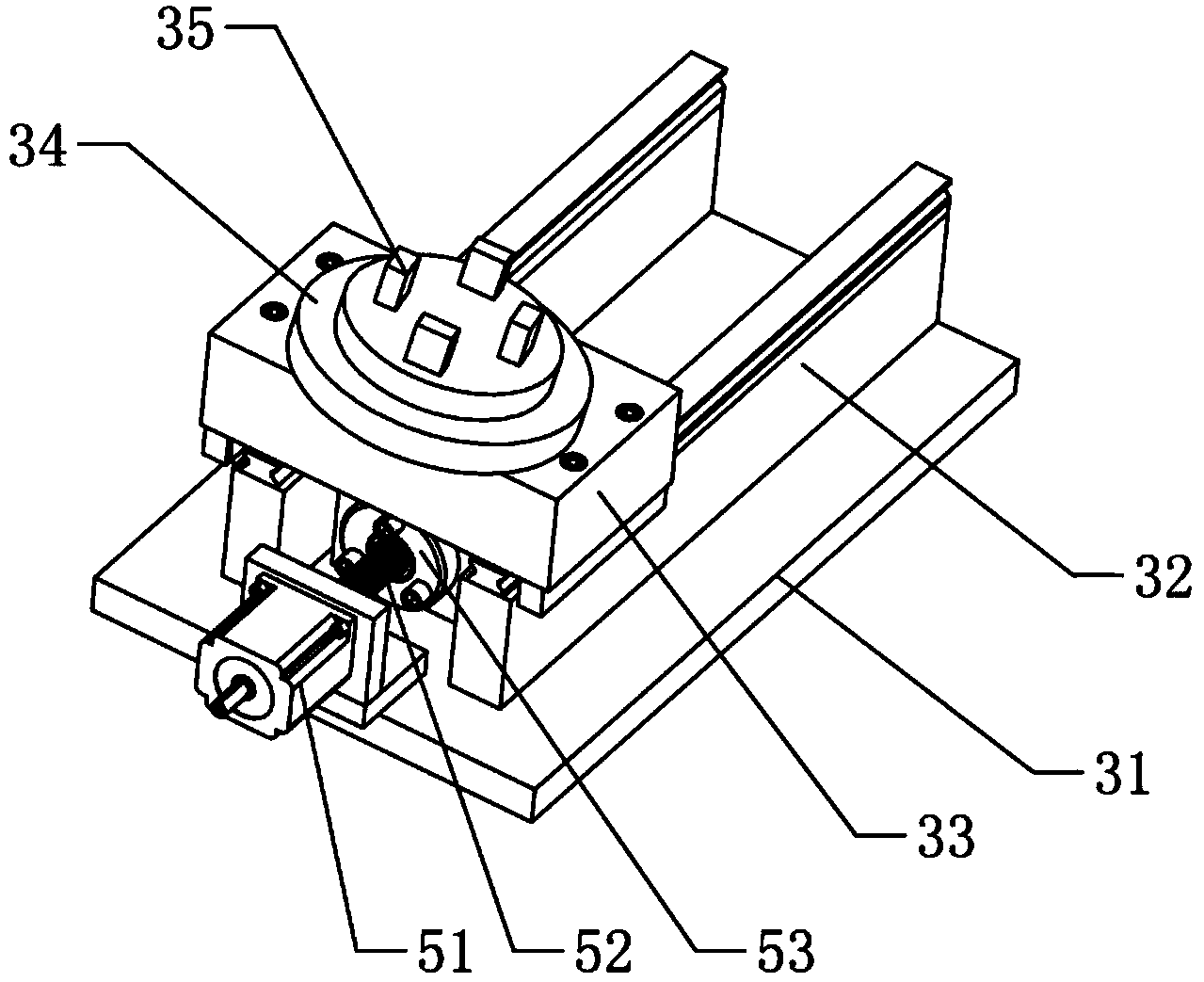

[0016] like Figure 1 to Figure 3 The shown vertical circular seam automatic pipe welding machine includes a vertical frame 1, a welding torch assembly located on the top of the frame 1, and a workbench 30 located at the bottom of the frame 1 and matched with the welding torch assembly. The welding torch assembly includes The box body 20 fixed on the frame 1, the first drive mechanism set in the box body 20, the welding torch 21 connected with the first drive mechanism, and the arc starter set on the welding torch 21 and matched with the welding torch 21 22. The frame 1 is also provided with a control panel 10, and the first driving mechanism includes a cylinder for controlling the vertical lifting of the welding torch 21, and a solenoid valve matched with the cylinder. The operating state of the cylinder is controlled by the solenoid valve, and then the vertical heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com