Cleaning method for filter core used for hydrogen peroxide production process

A production process, hydrogen peroxide technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of long time, affecting production and operation, and achieve the effect of simple equipment, flexible maintenance plan and arrangement, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

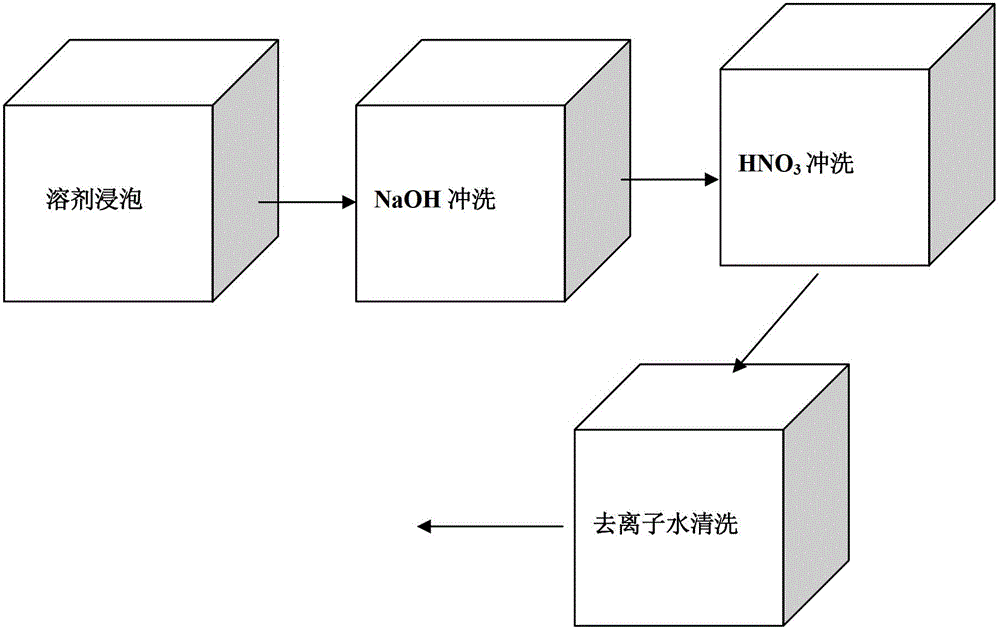

[0014] Such as figure 1 As mentioned above, a method for cleaning the filter element used in the production process of hydrogen peroxide, the filter element is first placed in the solvent benzene and soaked for 1 h, then placed in lye, that is, NaOH with a mass concentration of 3%, and cleaned for 0.5 h, and then placed in acid solution, that is, the mass concentration Concentration of 2% HNO 3 Neutralize, and finally rinse with deionized water for 3 times.

Embodiment 2

[0016] A method for cleaning a filter element used in a hydrogen peroxide production process. First, the filter element is soaked in solvent benzene for 2 hours, then placed in lye, that is, NaOH with a mass concentration of 10%, and cleaned for 2 hours, and then placed in an acid solution, that is, a mass concentration of 8%. HNO 3 Neutralize in neutralization, then soak in benzene solvent again for 2 hours, then place in lye, that is, NaOH with a mass concentration of 10%, wash for 2 hours, and then place in acid solution, that is, HNO with a mass concentration of 8%. 3 Neutralize, cycle twice, and finally rinse in deionized water for 5 times.

Embodiment 3

[0018] Such as figure 1 As mentioned above, a method for cleaning the filter element used in the production process of hydrogen peroxide, the filter element is first placed in the solvent trimethylbenzene and soaked for 1.5 hours, then placed in lye, that is, NaOH with a mass concentration of 5%, and cleaned for 1 hour, and then placed in acid solution. The mass concentration is 5% HNO 3 Neutralize, cycle three times in turn, and finally rinse in deionized water for four times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com