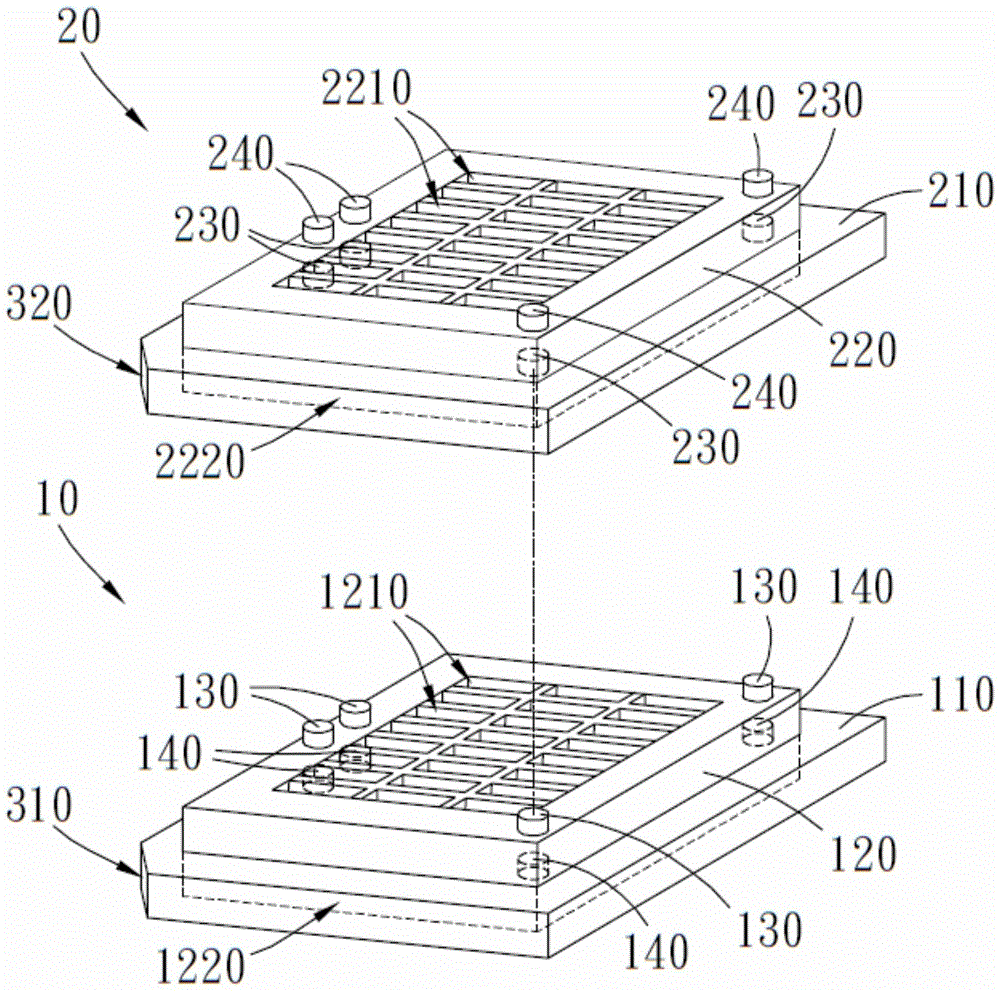

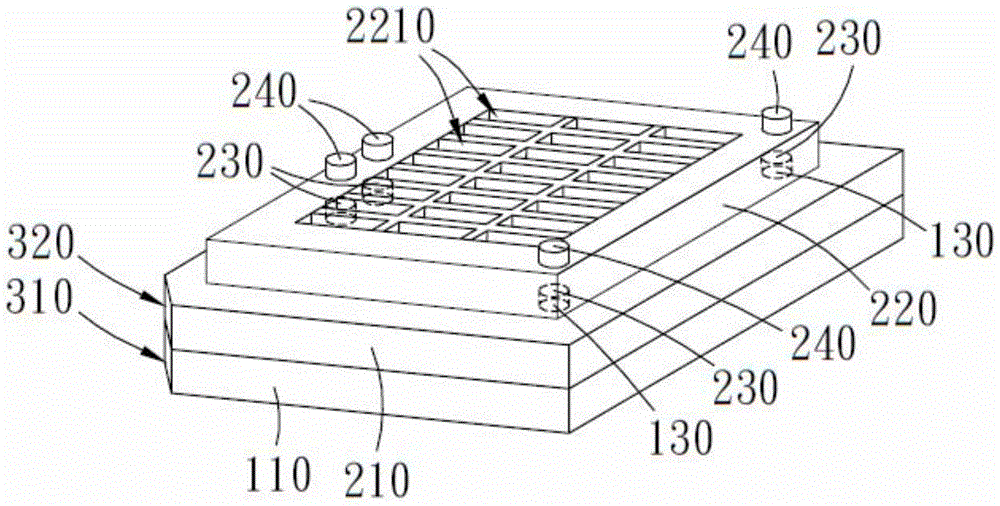

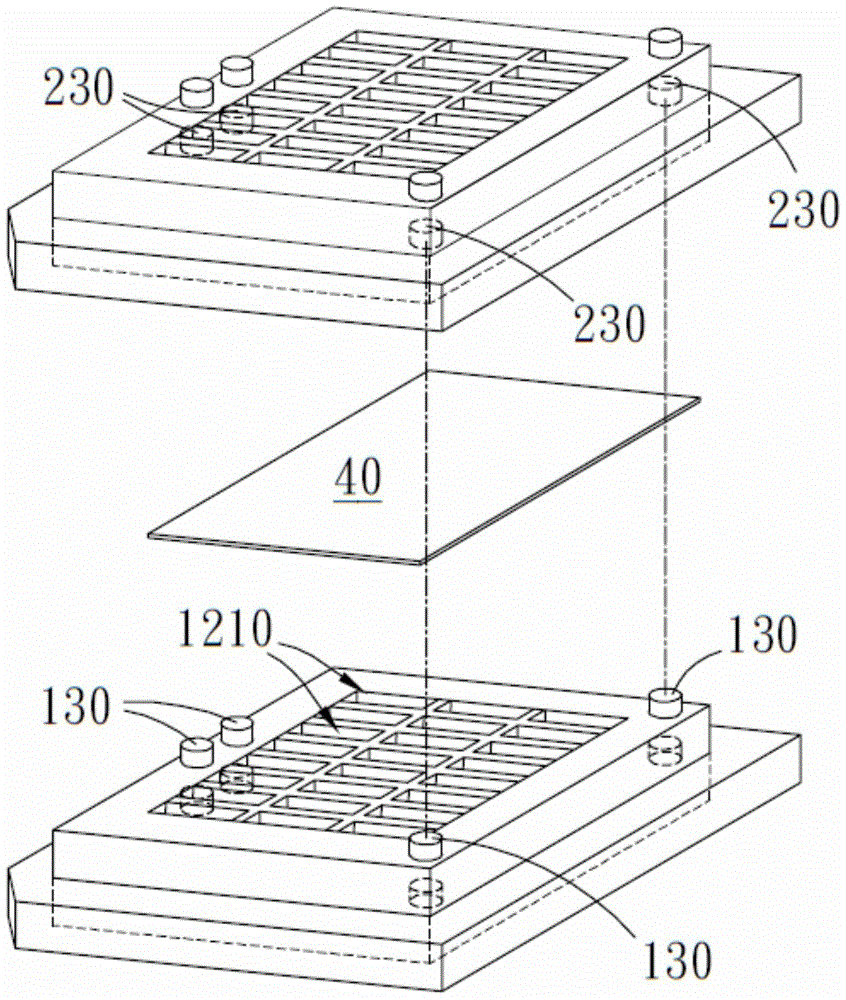

The structure of the chip carrier

A carrier plate and chip technology, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of high cost of double-sided chip carrier, poor process stability of double-sided chip carrier, and poor stacking of chip carrier. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the structural features of the present invention and the achieved effects have a further understanding and recognition, preferred embodiments and detailed descriptions are specially used, which are described as follows:

[0060] The present invention solves the problems related to the structure of the chip carrier in the prior art. In the process of bonding the chip to the substrate, the chip placed in the chip carrier sometimes needs to be turned over and placed upside down in the chip carrier. Flipping the chips one by one manually has a high error rate and is time-consuming, while using a double-sided chip carrier to place the chips costs a lot, and the stability of the manufacturing process of the double-sided chip carrier is poor. In addition, the conventional chip carrier The mechanism for preventing wrong stacking direction of the disc is insufficient, and the conventional chip carrier cannot fix the protective paper on the chip carrier. In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com