High uniformity aln film grown on sapphire substrate and its preparation method and application

A uniformity and substrate technology, applied in the field of high uniformity AlN thin film and its preparation, can solve the problems of high cost, low LED luminous efficiency, and difficulty in preparing high uniformity AlN thin film, so as to improve utilization rate, Unique growth process with reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

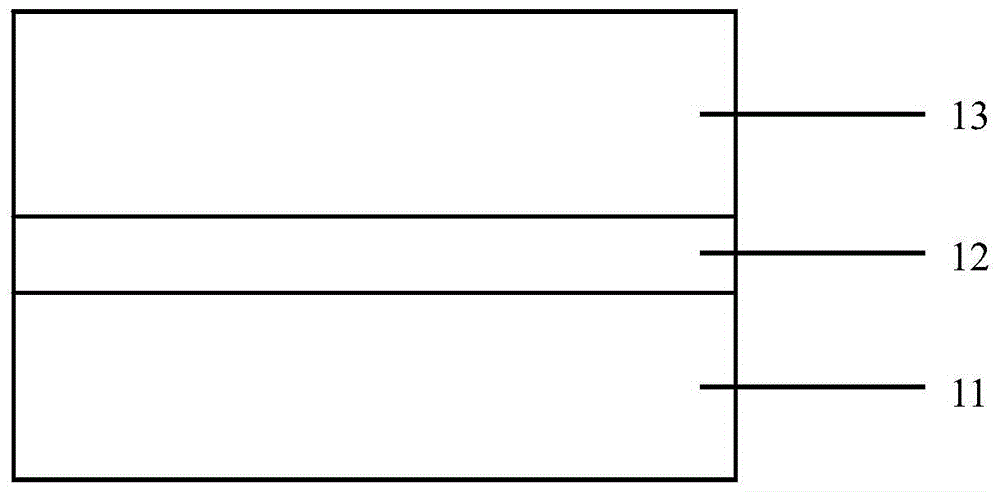

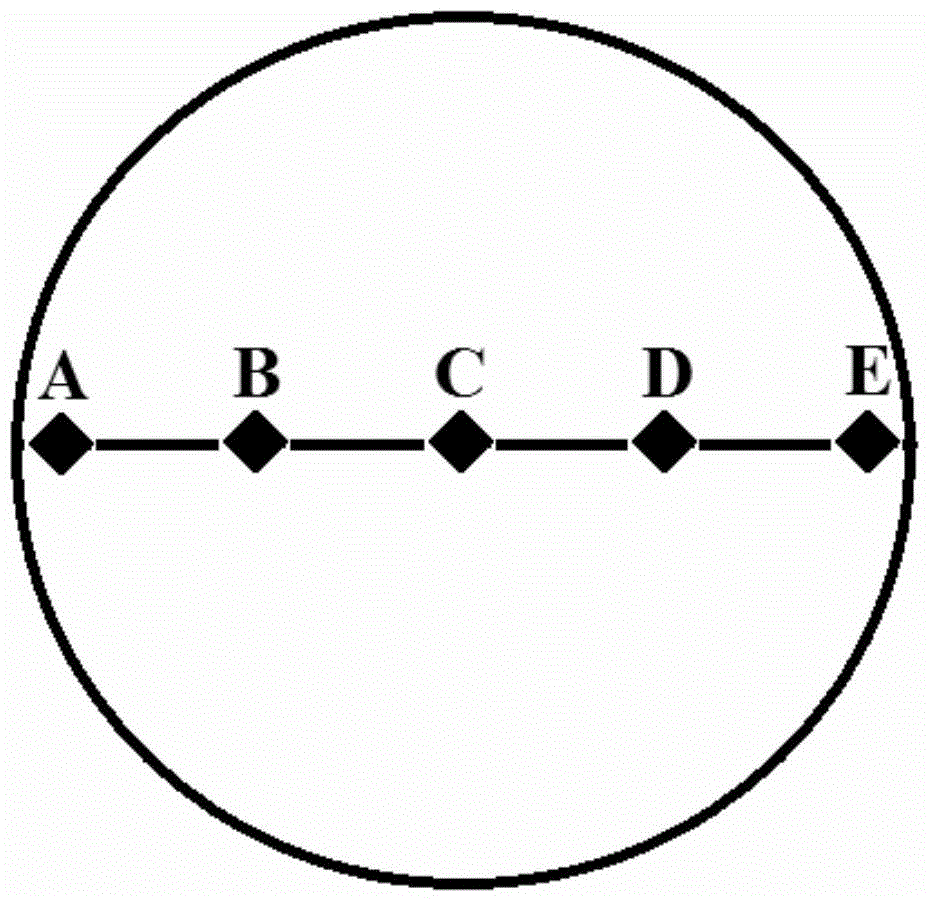

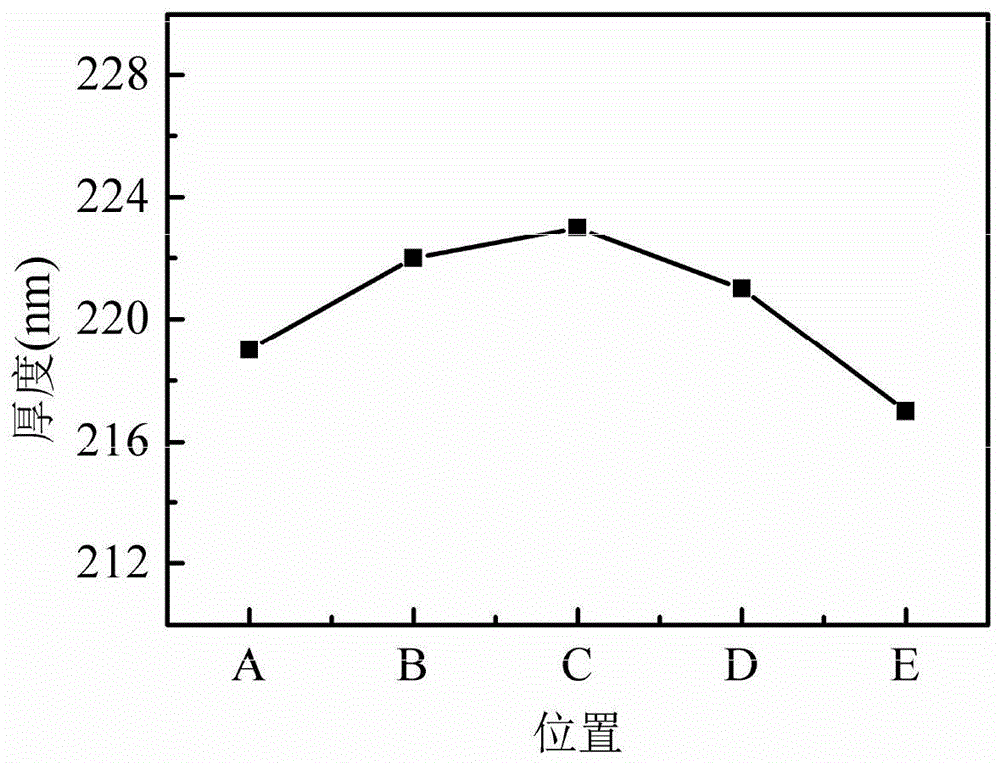

[0031] combine Figure 1-3 . A kind of AlN thin film grown on the sapphire substrate (see attached figure 1 ), including those grown on Al 2 o 3 The substrate (11) and its (0001) plane deviate 0.2° towards the (10-10) plane as the AlN nucleation layer (12) grown on the crystal epitaxial direction, and the AlN thin film grown on the AlN nucleation layer (12) (13). The thickness of the AlN nucleation layer (12) is 6nm, the thickness of the AlN thin film (13) is 220nm, and the unevenness is 2.69%.

[0032] The preparation method of the AlN thin film grown on the sapphire substrate of the present embodiment is made by the following steps:

[0033] a. Al 2 o 3 The substrate is cleaned and annealed; the specific process of the annealing is: the substrate is placed in the annealing chamber, and the Al 2 o 3 The substrate is annealed for 1 hour; the cleaning is specifically: Al 2 o 3 The substrate was ultrasonically cleaned in deionized water for 3 minutes at room temperatu...

Embodiment 2

[0042] This example is carried out on the basis of Example 1, the difference is that: the thickness of the AlN nucleation layer (12) is 10nm, the thickness of the AlN film (13) is 150nm, and the non-uniformity is 2.61 %.

Embodiment 3

[0044] This example is carried out on the basis of Example 1, the difference is that: the thickness of the AlN nucleation layer (12) is 5nm, the thickness of the AlN film (13) is 250nm, and the non-uniformity is 1.98 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com